Multipurpose coated paper and production process thereof

A production process and technology of coated paper, applied in the field of coated paper, to achieve the effect of bright printing color, excellent coating strength and reducing stocking quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

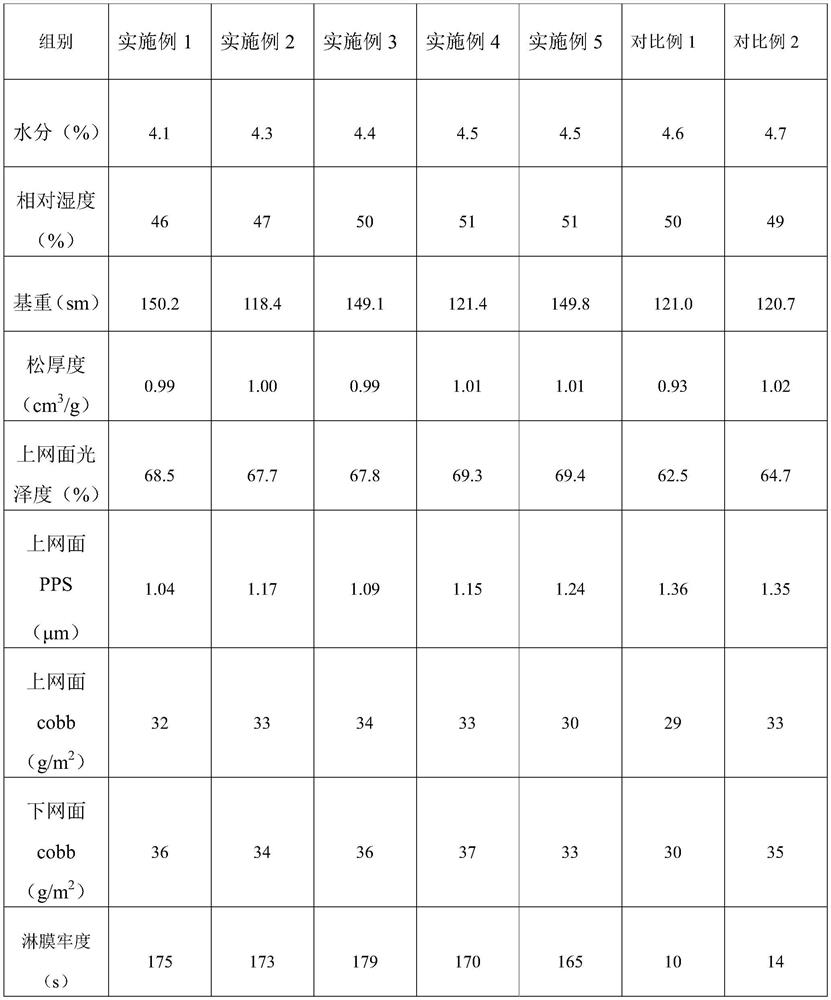

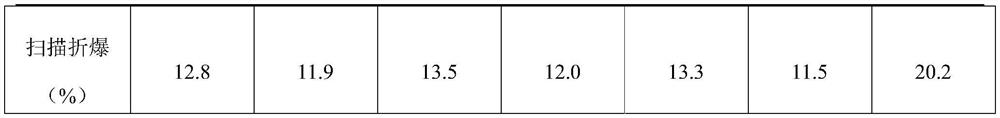

Examples

Embodiment 1

[0028] The production technology of embodiment 1 multipurpose coated paper

[0029] (1) Bleached hardwood kraft pulp, bleached softwood kraft pulp and alkaline hydrogen peroxide mechanical pulp with a mass ratio of 80:5:15 were mixed to obtain dry pulp.

[0030] (2) Add 20% ground calcium carbonate, positive starch 8kg / t, positive polyacrylamide retention aid 100ppm, colloidal silicon dioxide 4.0kg / t and alkenyl succinic anhydride sizing agent 1.5kg according to the absolute dry slurry quality / t, mixed to obtain base paper dry pulp, the base paper dry basis weight is 100gsm, moisture content is 7%, the ground calcium carbonate adopts C60 grade, and the particle size in the ground calcium carbonate is less than or equal to 2 μm The particle content is 60%.

[0031] (3) The dry pulp of the base paper is made by a single-layer wire, and the ratio of the pulp to the wire is 1.050, and the base paper is obtained.

[0032] (4) Base paper uses enzymatic starch coating for surface ...

Embodiment 2

[0037] The production technology of embodiment 2 multi-purpose coated paper

[0038] (1) Bleached hardwood kraft pulp with a mass ratio of 85:15 and alkaline hydrogen peroxide mechanical pulp were mixed to obtain dry pulp.

[0039](2) Add 10% ground calcium carbonate, positive starch 5kg / t, positive polyacrylamide retention aid 50ppm, colloidal silicon dioxide 3.0kg / t and alkenyl succinic anhydride sizing agent 1.0kg according to the absolute dry slurry quality / t, mixed to obtain base paper dry slurry, the base paper dry basis weight is 75gsm, moisture content is 5%, the ground calcium carbonate adopts C60 grade, and the particle size in the ground calcium carbonate is less than or equal to 2 μm The particle content is 60%.

[0040] (3) The dry pulp of the base paper is made by a single-layer wire, and the ratio of the pulp to the wire is 1.040, and the base paper is obtained.

[0041] (4) Base paper uses enzymatic starch coating to carry out surface sizing, the amount of g...

Embodiment 3

[0046] The production technology of embodiment 3 multi-purpose coated paper

[0047] (1) Bleached hardwood kraft pulp, bleached softwood kraft pulp and alkaline hydrogen peroxide mechanical pulp with a mass ratio of 76:8:16 were mixed to obtain dry pulp.

[0048] (2) Add 12.8% ground calcium carbonate, positive starch 6kg / t, positive polyacrylamide retention aid 80ppm, colloidal silicon dioxide 3.6kg / t and alkenyl succinic anhydride sizing agent 1.4kg according to the absolute dry slurry quality / t, mixed to obtain base paper dry slurry, the base paper dry basis weight is 101gsm, moisture content is 6.6%, the ground calcium carbonate adopts C60 grade, and the particle size in the ground calcium carbonate is less than or equal to 2 μm The particle content is 60%.

[0049] (3) The dry pulp of the base paper is made by a single-layer wire, and the ratio of the pulp to the wire is 1.045, and the base paper is obtained.

[0050] (4) Base paper uses enzymatic starch coating to car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com