Method for determining content of components in iron ore by X-ray fluorescence spectrometry

The technology of fluorescence spectrometry and fluorescence spectrometer is applied in the field of X-ray fluorescence spectrometry to determine the content of components in iron ore, which can solve the problems of long inspection period, high maintenance cost, poor decoating effect, etc., so as to improve the service life, The effect of reducing maintenance costs and shortening inspection cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

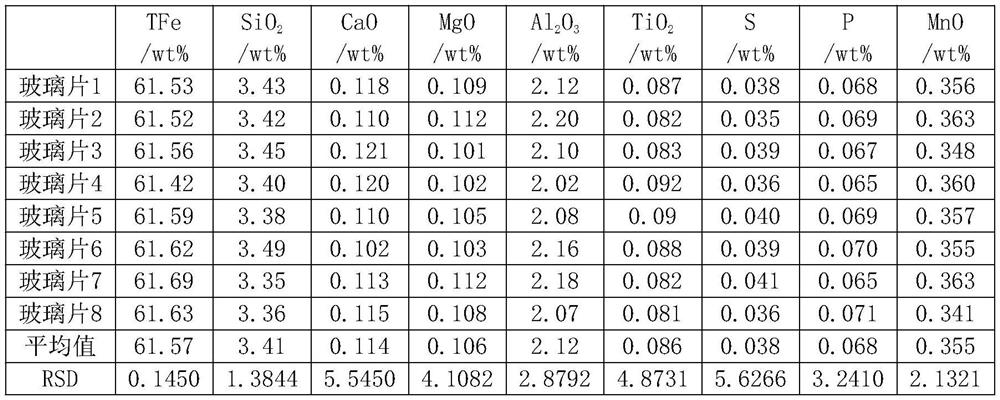

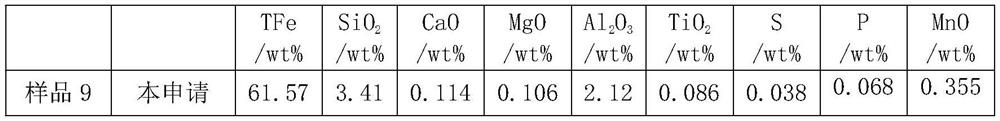

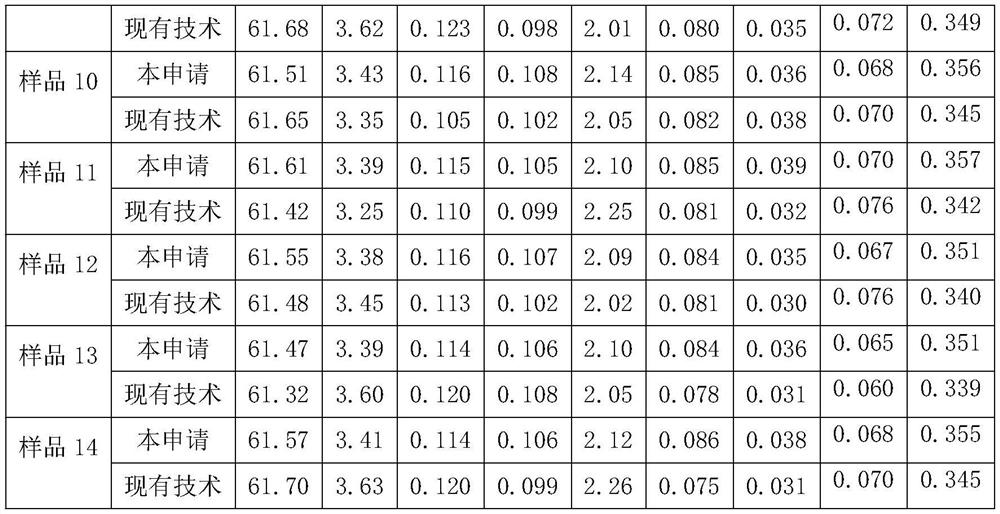

Examples

Embodiment 1

[0047] A method for determining the content of components in iron ore by X-ray fluorescence spectrometry, comprising the following steps in sequence:

[0048] 1) Iron ore sample, mixed flux, oxidizing agent, cobalt powder and release agent are loaded into platinum crucible, and the release agent is ammonium bromide;

[0049] In step 1), the mixed flux is lithium tetraborate and lithium metaborate, the quality of lithium tetraborate: the quality of lithium metaborate=67%:33%;

[0050] The oxidizing agent is potassium nitrate;

[0051] Add water to ammonium bromide and be mixed with the aqueous solution of ammonium bromide, the concentration of the aqueous solution of ammonium bromide is 200g / L, add 10 drops of aqueous solution of ammonium bromide;

[0052] The mass of iron ore sample is 0.2000g±0.0001g, the mass of mixed flux is 7.0000g±0.0005g, the mass of oxidant is 0.5000g±0.0002g, and the mass of cobalt powder is 0.2000g±0.0001g;

[0053] 2) heating and melting the mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com