Burner for producing inorganic spheroidized particles, device for producing inorganic spheroidized particles, and method for producing inorganic spheroidized particles

A burner and inorganic technology, applied in the direction of combustion methods, chemical instruments and methods, burners, etc., can solve the problems that cannot fully ensure the residence time of the burner flame (heating time, unable to give heat, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078]

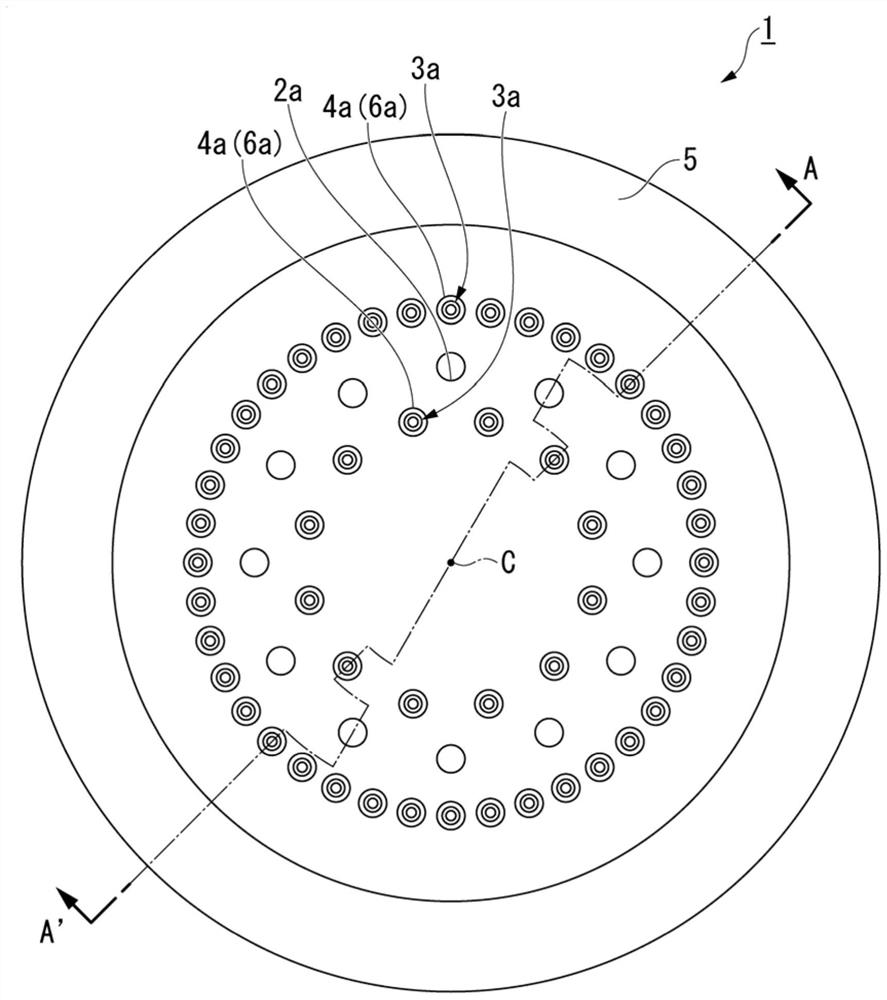

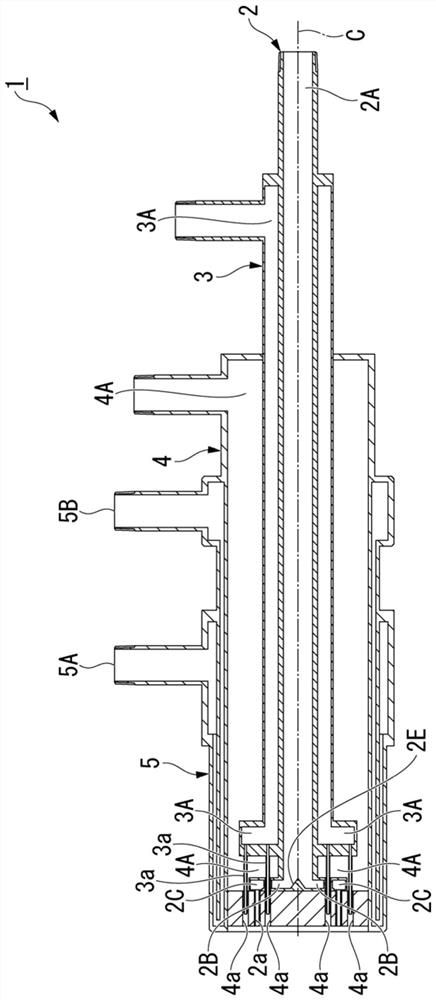

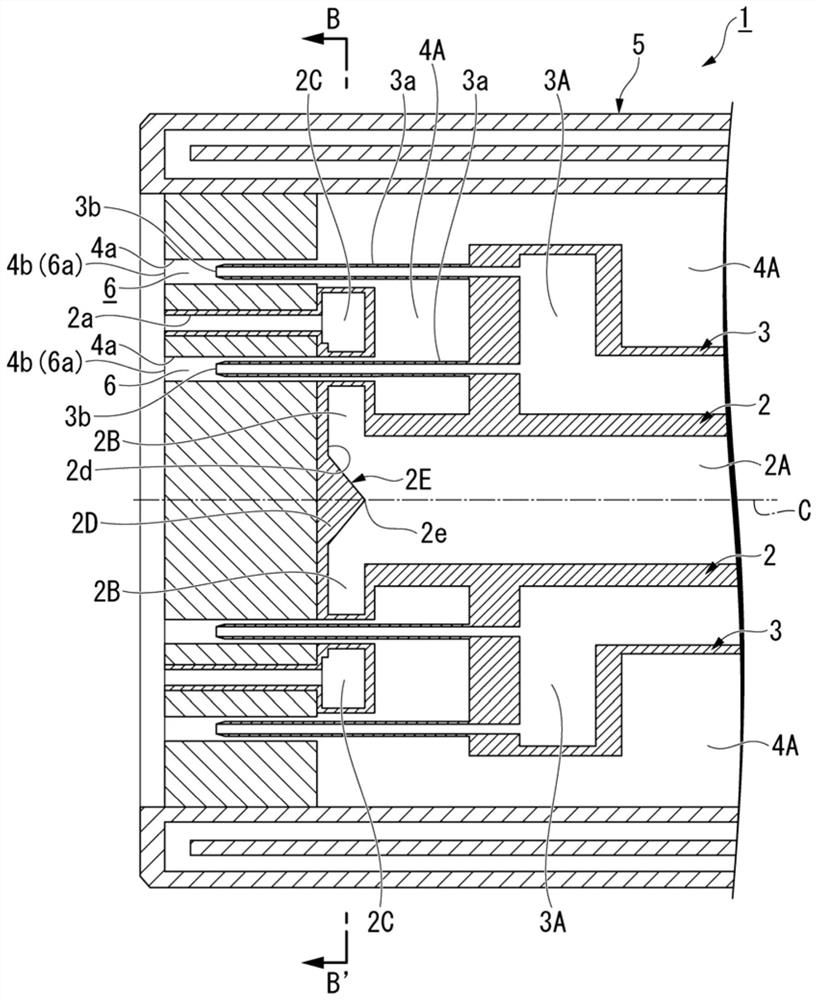

[0079] Hereinafter, a burner for producing spheroidized inorganic particles as a first embodiment to which the present invention is applied will be described in detail together with an apparatus for producing spheroidized inorganic particles and a production method using the same, using the drawings. In addition, in the drawings used in the following description, characteristic parts may be shown enlarged for the sake of easy understanding of features and for convenience, and the dimensional ratio of each component may not necessarily be the same as the actual one.

[0080] (Burner for manufacturing inorganic spheroidized particles)

[0081] First, the structure of the burner for producing spheroidized inorganic particles according to the first embodiment will be described. Figure 1 to Figure 4 A burner for producing spheroidized inorganic particles (hereinafter, may be simply referred to as a "burner") as a first embodiment to which the present invention is applie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com