A polydopamine-coated sustained-release MNO 2 Nanoparticle drug delivery system

A nano-microsphere and drug-carrying system technology, applied in the field of biomedicine, can solve the problems of high toxicity and side effects, low selection specificity, and application limitations, and achieve the effects of high targeting, good biocompatibility, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] Provide the aforementioned sustained-release MnO 2 The preparation method of the new drug-carrying system of nano-microspheres includes:

[0076] Step 1: The glucose solution with a concentration of 0.01-0.5M is transferred to a tetrafluoroethylene autoclave, hydrothermally reacted at a temperature of 150-300 ° C for at least 12 hours to obtain a brown precipitate, washed several times with deionized water and absolute ethanol, Dry in a blast oven at 60-90 °C to obtain carbon nanospheres;

[0077] Step 2: Nano carbon balls are ultrasonically dispersed in deionized water to obtain a nano carbon ball water dispersion, adjusted to 1-5 with concentrated HCl, according to nano carbon balls and KMnO 4 Powder weight ratio of 1:2-4 is added to KMnO 4 Powder, continue to ultrasonically disperse for at least 10min, react at 80-150℃ for 30min-12h, and generate MnO in situ 2 , washed with deionized water and absolute ethanol, dried, and sintered at 200-500 °C for not less than 2...

Embodiment 1

[0089] Provide a slow-release MnO 2 A new drug-loading system for nano-microspheres, specifically pH-controlled release and folic acid-targeted drug-loading MnO 2 Nanocomposite hollow sphere, its preparation process is as follows figure 1 As shown, the preparation method includes the following steps.

[0090](1) Preparation of carbon nanospheres: magnetically stir 0.1M 30mL glucose solution uniformly and transfer it to a 50mL tetrafluoroethylene autoclave for hydrothermal reaction at 180°C for 15h; deionized water is used for the obtained brown precipitate and anhydrous ethanol were washed 3 times respectively, placed in an 80°C blast oven and dried to constant weight to obtain carbon nanospheres.

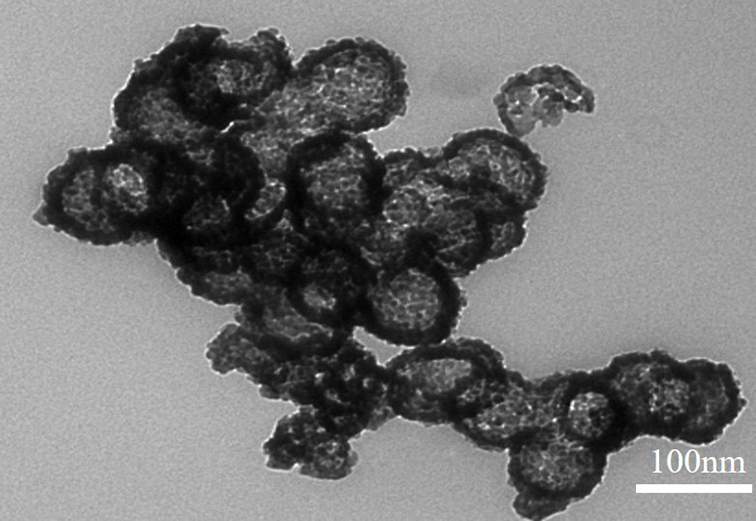

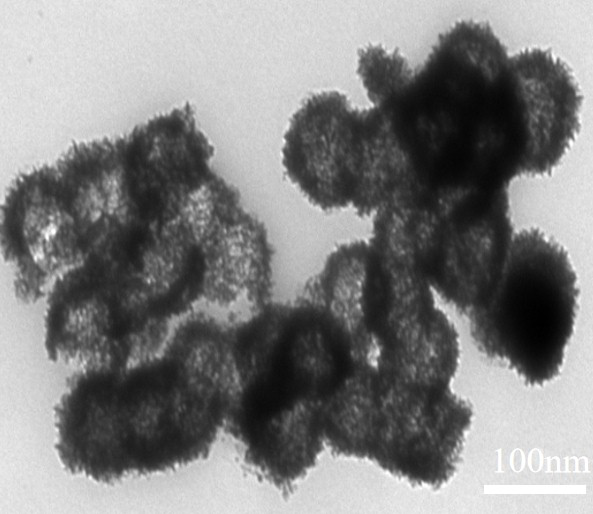

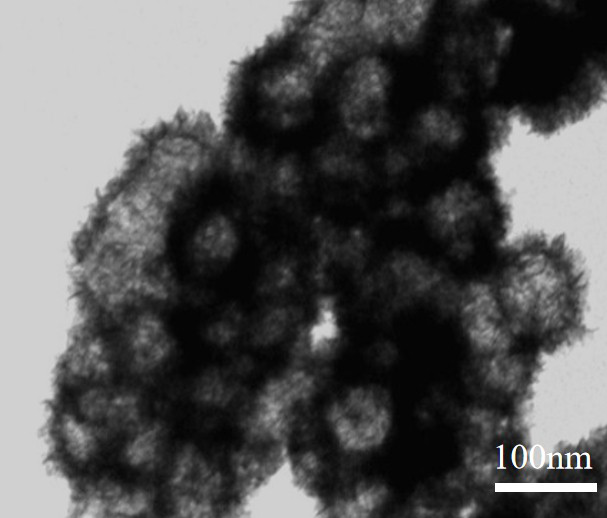

[0091] (2) Preparation of MnO 2 Nano hollow sphere: Ultrasonic 0.042g nano carbon sphere (35KHz, 0.4W / cm 2 ) was dispersed in 20 mL of deionized water, and the pH was adjusted to 2.5 with concentrated HCl; then 0.111 g of KMnO was added to the suspension 4 Powder, continue to ...

Embodiment 2

[0096] Characterization of nanomaterials, the potential of nanomedicines at different pH values (5.0 and 7.4) was tested using a Malvern nanoparticle size analyzer. The result is as Image 6 As shown, at pH=7.4 (simulating the blood environment in vivo), all the prepared nanomaterials are negatively charged, indicating that the negatively charged nanomedicines can avoid the adsorption of proteins in vivo, can reduce the toxic effects of drugs in vivo, prolong the Circulation cycle of drugs in vivo; at pH=5.0 (simulating tumor microenvironment), MnO 2 @DOX is coated with PDA and then modified with -NH 2 make MnO 2 @DOX-NH 2 Shows strong positive charge, realizes charge inversion, and the final MnO 2 @DOX-NH 2 The -FA composite nanomedicine is positively charged, which helps the nanomedicine to aggregate to the tumor cells with negatively charged surface, so that the drug can be targeted and concentrated, which is convenient for targeted drug delivery and improves the the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com