Desulfurizing agent for preventing desulfurization enriching agent from hardening at low temperature and preparation method of desulfurizing agent

A technology of desulfurization enrichment agent and desulfurization agent, which is applied in the direction of separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of small sulfur capacity of desulfurization agent and easy hardening of desulfurization enrichment agent, so as to ensure the specific surface area and avoid Burst, meet the effect of high precision and high sulfur capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

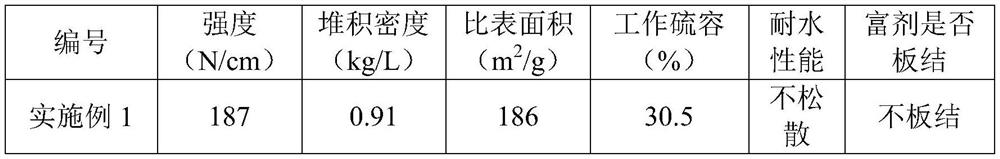

Embodiment 1

[0030] A desulfurizing agent for preventing hardening of the desulfurizing enrichment agent at low temperature, comprising the following raw materials proportioned by weight: 50 parts of ferric oxide, 10 parts of basic zinc carbonate, 20 parts of pseudo-boehmite, diatomaceous earth 10 parts, 2.0 parts of binder sodium carboxymethyl cellulose, 5 parts of water glass, 3.5 parts of lubricant graphite.

[0031] Among them, the particle size of ferric oxide, basic zinc carbonate and pseudo-boehmite is 150-180 mesh.

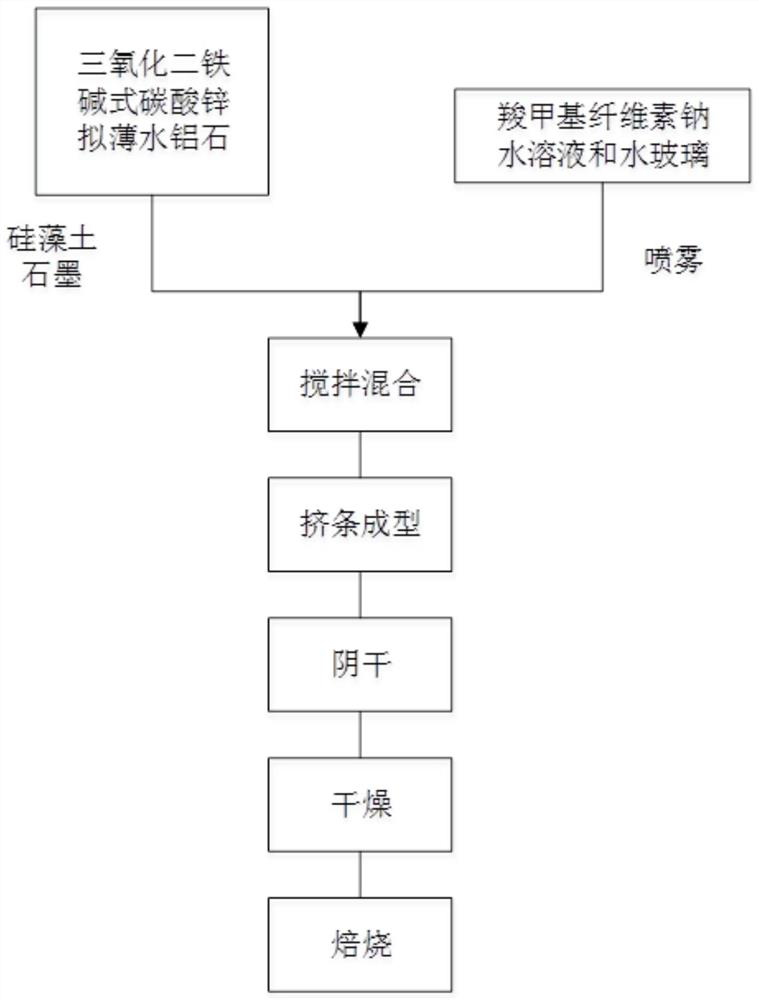

[0032] A kind of preparation method of the desulfurization agent that prevents desulfurization enrichment agent from forming compaction at low temperature, comprises the following steps:

[0033] Step (1): Ferric oxide, pseudo-boehmite and basic zinc carbonate are pulverized with a ball mill respectively, and sieved after pulverization, and the sieved meshes are 150 mesh and 180 mesh;

[0034] Step (2): Mixing ferric oxide, pseudoboehmite, basic zinc carbonate, diatom...

Embodiment 2

[0041] A desulfurizing agent for preventing hardening of the desulfurizing enrichment agent at low temperature, comprising the following raw materials proportioned by weight: 50 parts of ferric oxide, 10 parts of basic zinc carbonate, 20 parts of pseudo-boehmite, diatomaceous earth 10 parts, 2.5 parts of binder sodium carboxymethyl cellulose, 5 parts of water glass, 3.0 parts of lubricant graphite.

[0042] Among them, the particle sizes of ferric oxide, basic zinc carbonate and pseudo-boehmite are all 150-180 mesh.

[0043] A kind of preparation method of the desulfurization agent that prevents desulfurization rich agent from forming compaction at low temperature, comprises the following steps:

[0044] Step (1): Ferric oxide, pseudo-boehmite and basic zinc carbonate are pulverized with a ball mill respectively, and sieved after pulverization, and the sieved meshes are 150 mesh and 180 mesh;

[0045] Step (2): Mixing ferric oxide, pseudoboehmite, basic zinc carbonate, diatom...

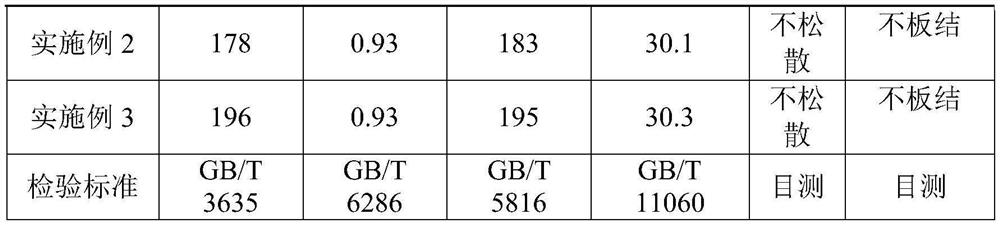

Embodiment 3

[0052] A desulfurizing agent for preventing hardening of the desulfurizing enrichment agent at low temperature, comprising the following raw materials proportioned by weight: 50 parts of ferric oxide, 10 parts of basic zinc carbonate, 20 parts of pseudo-boehmite, diatomaceous earth 10 parts, 2.5 parts of binder sodium carboxymethyl cellulose, 5 parts of water glass, 3.5 parts of lubricant graphite.

[0053] Among them, the particle size of ferric oxide, basic zinc carbonate and pseudo-boehmite is 150-180 mesh.

[0054] A kind of preparation method of the desulfurization agent that prevents desulfurization enrichment agent from forming compaction at low temperature, comprises the following steps:

[0055] Step (1): Ferric oxide, pseudo-boehmite and basic zinc carbonate are pulverized with a ball mill respectively, and sieved after pulverization, and the sieved meshes are 150 mesh and 180 mesh;

[0056] Step (2): Mixing ferric oxide, pseudoboehmite, basic zinc carbonate, diatom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com