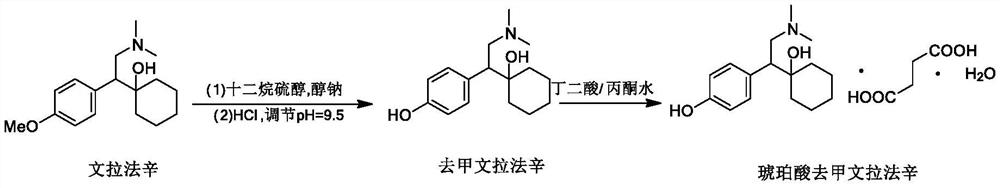

Preparation method of desvenlafaxine succinate

A technology of desvenlafaxine succinate and desvenlafaxine, applied in carboxylate preparation, carboxylate preparation, chemical instruments and methods, etc., can solve centrifugation difficulties, difficult industrialization, pull through Problems such as low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 desvenlafaxine succinate

[0030] Add 89.62kg of venlafaxine, sodium lauryl mercaptide (3.5eq), and N-methylpyrrolidone (3.0ml / g) into the reaction kettle, stir and heat up to 170-180°C, keep stirring and react for 6h, then cool down To below 50°C, add water (5ml / g) and ethyl acetate (4ml / g), control the temperature at 0-10°C, adjust the pH to 1 with concentrated hydrochloric acid, separate the liquids, and use ethyl acetate (4ml / g) for the aqueous phase Wash, control the temperature of the water phase at 20-30°C, add dropwise 40% sodium hydroxide aqueous solution to adjust the pH to 9-10, filter, measure the residue on ignition of the filter cake 2.5%, use purified water 6.8g / g for the filter cake, 20-30°C Beat for 0.5-1.0 hours, centrifuge, filter cake detection residue on ignition 0.06%, get desvenlafaxine wet product, weight 115.33 (kg), water content Wherein, m is the feeding amount of venlafaxine 89.62kg.

[0031] Add desvenlafax...

Embodiment 2

[0032] The preparation of embodiment 2 desvenlafaxine succinate

[0033] Add 85.12kg of venlafaxine, sodium lauryl mercaptide (3.5eq), and N-methylpyrrolidone (3.0ml / g) into the reaction kettle, stir and heat up to 170-180°C, keep stirring and react for 6h, then cool down When the temperature is below 50°C, add water (5ml / g) and ethyl acetate (4ml / g), control the temperature at 0-10°C, adjust the pH to 4 with concentrated hydrochloric acid, separate the liquid, and use dichloromethane (4ml / g) for the aqueous phase Wash, add 40% aqueous sodium hydroxide solution dropwise at 40-50°C to adjust the pH to 9-10 in the water phase, filter, measure the residue on ignition of the filter cake is 2.7%, use purified water 6.8g / g for the filter cake, 20-30°C Beat for 0.5-1.0 hours, centrifuge, filter cake detection residue on ignition 0.05%, get desvenlafaxine wet product, weight 108.11 (kg), water content Wherein, m is the feeding amount of venlafaxine 85.12kg.

[0034] Add desvenlafax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com