Telomer of aluminum diethylphosphinate and preparation method of telomer

A technology of diethylphosphinic acid and phenylethylphosphinate, which is applied in the field of preparation of aluminum diethylphosphinate, can solve the difficulty in meeting the requirements of phosphorus-containing wastewater treatment, low light conversion efficiency, Increase the distillation to remove the acetic acid solvent link and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

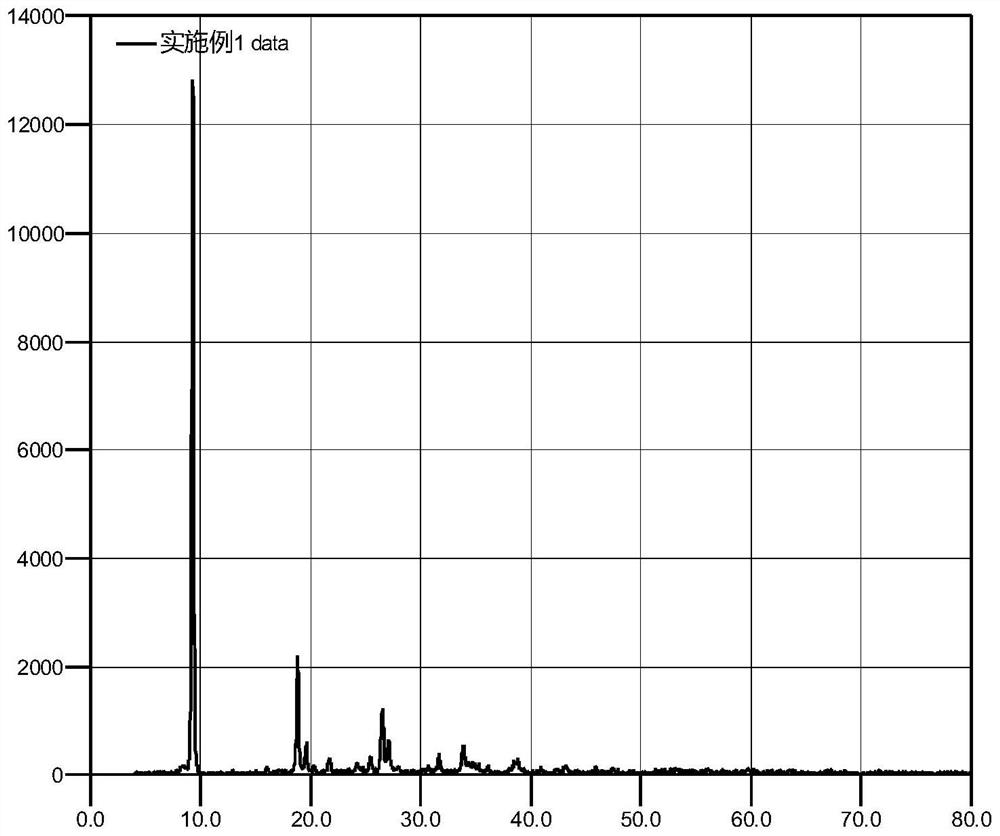

Embodiment 1

[0079] Sodium hypophosphite solution, configured into 227 grams per liter of solution, heated to 65 ° C, slowly added dropwise 1.5wt% acetophenone (calculated as sodium hypophosphite) and OP-10 mixture (the mixture of acetophenone and OP-10 The mass ratio is 1:1.0), after the air is replaced by nitrogen, ethylene is introduced to keep the pressure at 0.40MPa, and the microwave generator in the reactor is turned on to start the reaction. After reacting for 5 hours, every 30 minutes, start to detect whether the reaction is complete. The obtained reaction solution was raised to 90° C., and the reaction method with aluminum sulfate was the same as that of Comparative Example 1. The yield was 98% (calculated as phosphorus).

Embodiment 2

[0081] Sodium hypophosphite solution, configured into 227 grams per liter of solution, heated to 75 ° C, slowly added dropwise 4.5wt% acetophenone (calculated as sodium hypophosphite) and OP-10 mixture (the mixture of acetophenone and OP-10 The mass ratio is 1:1.0), after the air is replaced by nitrogen, ethylene is introduced to keep the pressure at 0.43MPa, and the microwave generator in the reactor is turned on to start the reaction. After reacting for 5 hours, every 30 minutes, start to detect whether the reaction is complete. The obtained reaction solution was raised to 90° C., and the reaction method with aluminum sulfate was the same as that of Comparative Example 1. The yield was 97% (calculated as phosphorus).

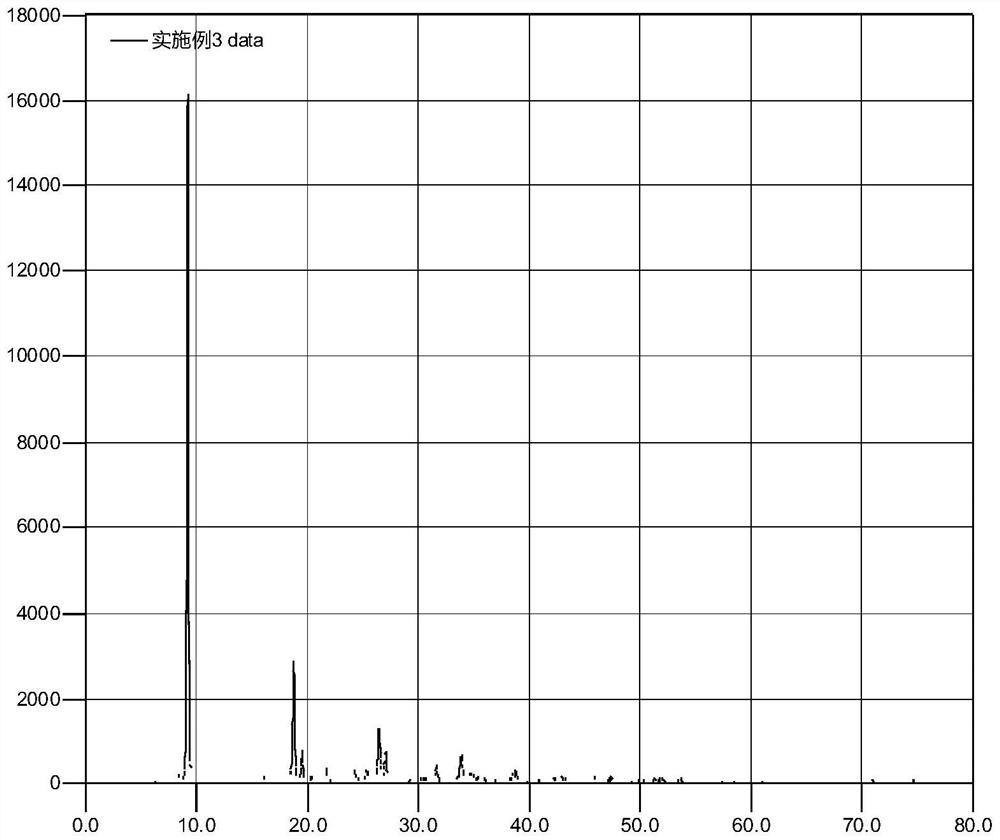

Embodiment 3

[0083] Sodium hypophosphite solution, configured into 227 g / L solution, heated to 85 ° C, slowly added dropwise 2.5wt% isobutyryl phenone (calculated as sodium hypophosphite) and OP-10 mixture (acetophenone and OP- The mass ratio of 10 is 1:1.0), after the air is replaced by nitrogen, ethylene is introduced to keep the pressure at 0.45MPa, and the microwave generator in the reactor is opened to start the reaction. After reacting for 5 hours, every 30 minutes, start to detect whether the reaction is complete. The obtained reaction solution was raised to 90° C., and the reaction method with aluminum sulfate was the same as that of Comparative Example 1. The yield was 98% (calculated as phosphorus).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com