Flow chemical synthesis method of chlorotrifluoroethylene copolymer

A technology of chlorotrifluoroethylene and synthesis method, which is applied in the field of polymer synthesis, and can solve the problems that there are no research reports on the polymerization of flow chemical gas monomers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

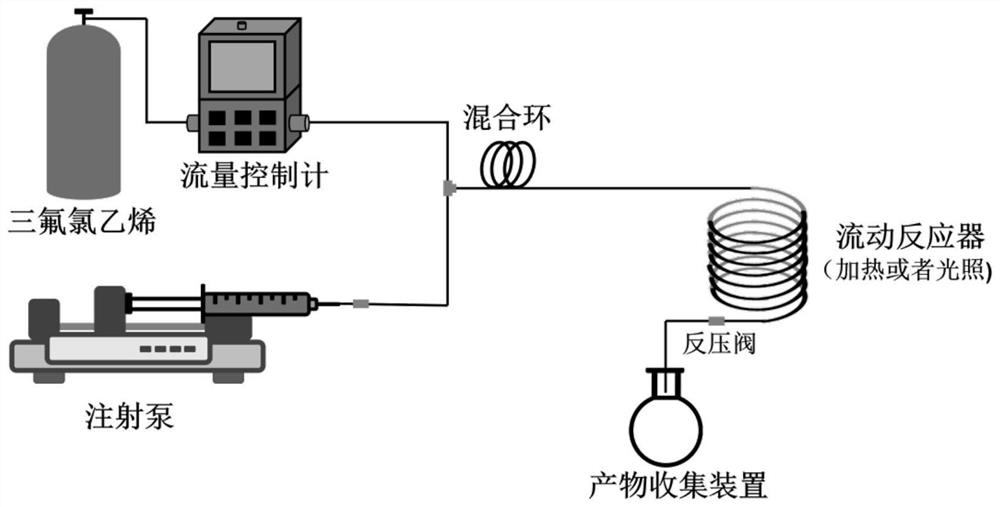

[0028] Embodiment 1: the heating flow chemical synthesis of chlorotrifluoroethylene and n-butyl vinyl ether copolymer

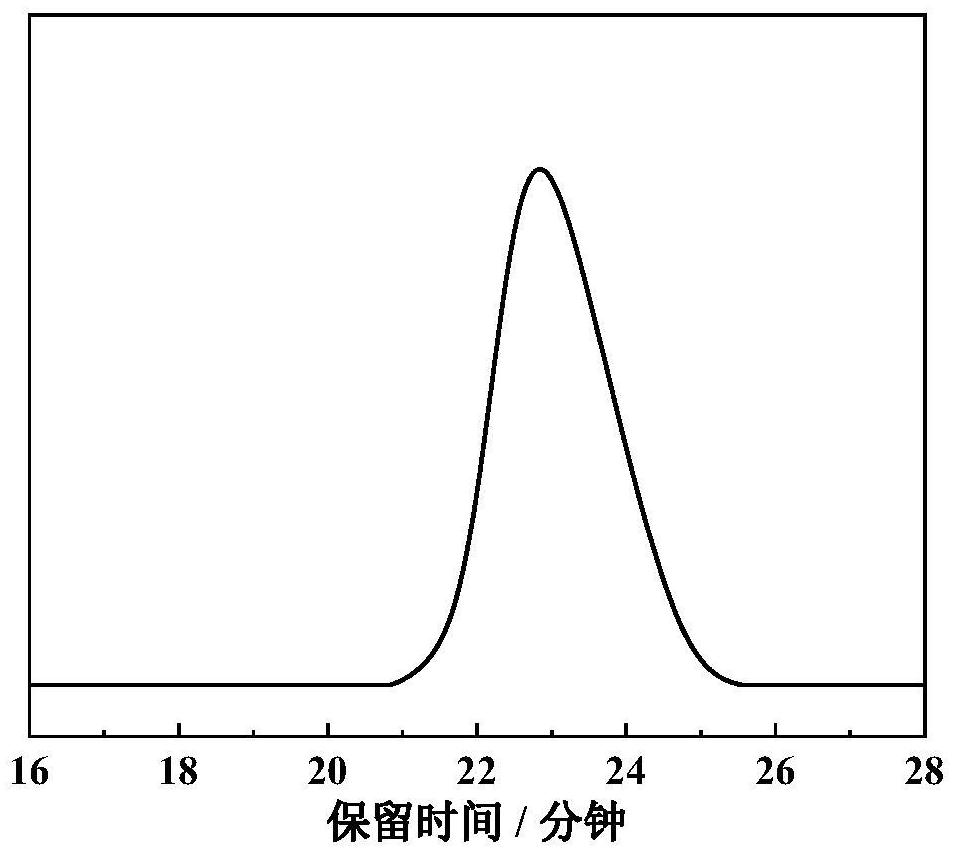

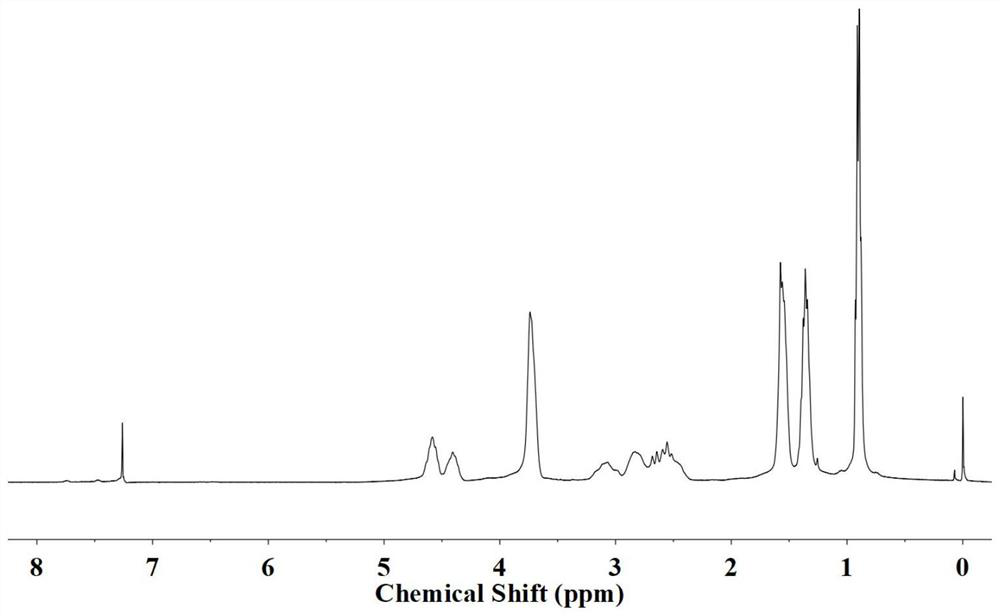

[0029] According to the molar ratio of n-butyl vinyl ether: AIBN = 1000: 1, add 20 mmol and 0.02 mmol of the above raw materials into the glass bottle in turn, then add 20 mL of diethyl carbonate to dissolve each component, and blow nitrogen gas to remove the reaction solution Oxygen in the figure 1 on the syringe pump shown. The pressure of the back pressure valve at the end of the flow reactor is 60 psi. After connecting all parts of the device and immersing the flow reactor in a constant temperature oil bath at 80 °C, set the flow rate of the gas flow control meter to 1 SCCM, and the flow rate of the syringe pump Set at 20 μL / min. Chlorotrifluoroethylene gas and reaction liquid are mixed through the mixing ring, and then flow into the reactor for copolymerization. After reacting for 1 hour, collect the solution after the reaction at the outlet, and pass...

Embodiment 2

[0030] Embodiment 2: The light flow chemical synthesis of chlorotrifluoroethylene and n-butyl vinyl ether copolymer

[0031]According to the molar ratio of n-butyl vinyl ether: TPO = 1000: 1, add 20 mmol and 0.02 mmol of the above raw materials into the glass bottle in turn, then add 20 mL of diethyl carbonate to dissolve each component, and blow nitrogen gas to remove the reaction solution Oxygen in the figure 1 on the syringe pump shown. The pressure of the back pressure valve at the end of the flow reactor is 40 psi, connect all parts of the device and place the flow reactor under the irradiation of a 450 nm blue light, set the flow rate of the gas flow controller to 1 SCCM, and set the flow rate of the syringe pump to 1 SCCM. Set at 20 μL / min. Chlorotrifluoroethylene gas and reaction liquid are mixed through the mixing ring, and then flow into the reactor for copolymerization. After reacting for 1 hour, collect the solution after the reaction at the outlet, and pass 1 ...

Embodiment 3

[0032] Embodiment 3: the heating flow chemical synthesis of chlorotrifluoroethylene and vinyl acetate copolymer

[0033] According to the molar ratio of vinyl acetate: AIBN = 1000: 1, add 20 mmol and 0.02 mmol of the above raw materials into the glass bottle in sequence, then add 20 mL of diethyl carbonate to dissolve each component, blow nitrogen gas to remove the oxygen in the reaction solution , then transferred to a syringe and secured the syringe in the figure 1 on the syringe pump shown. The pressure of the back pressure valve at the end of the flow reactor is 60 psi. After connecting all parts of the device and immersing the flow reactor in a constant temperature oil bath at 80 °C, set the flow rate of the gas flow control meter to 2 SCCM, and the flow rate of the syringe pump Set at 40 μL / min. Chlorotrifluoroethylene gas and reaction liquid are mixed through the mixing ring, and then flow into the reactor for copolymerization. After reacting for 0.5 hours, collect t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com