Preparation method and application of castor oil-based polyamide capable of being cross-linked by ultraviolet light

An oil-based polyamide and castor oil-based technology, which is applied in the field of polymers, can solve the problems of thermoplastic elastomers such as unrecoverable properties and complex methods, and achieve the effects of expanding the scope of use, simple preparation methods, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

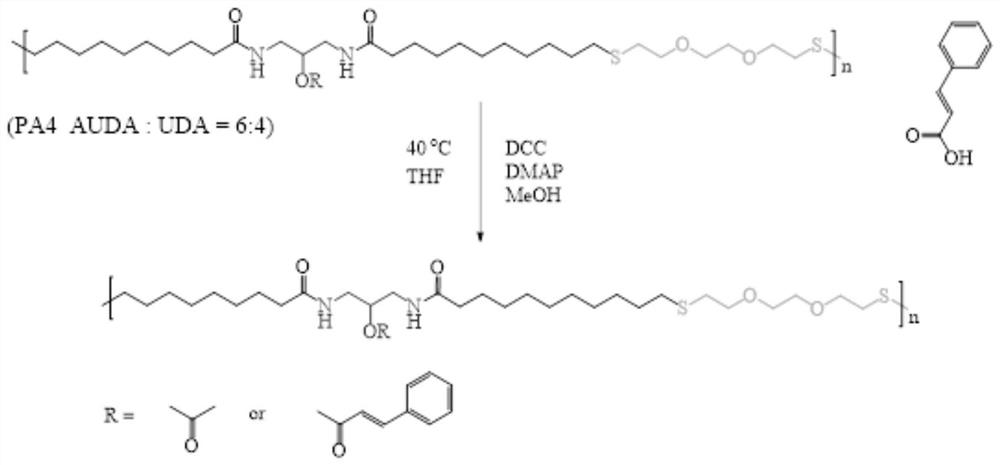

[0055] The preparation of castor oil-based functional polyamide comprises the following steps:

[0056] 13g parts by weight functional polyamide monomer 1, 14g functional polyamide monomer 2, 12g oxadithiol and 0.1g azobisisobutyronitrile catalyst were dissolved in 25mL tetrahydrofuran solvent; Minutes, placed in a 65°C oil bath for 24 hours of reaction; finally, the functional polyamide product was obtained by methanol precipitation.

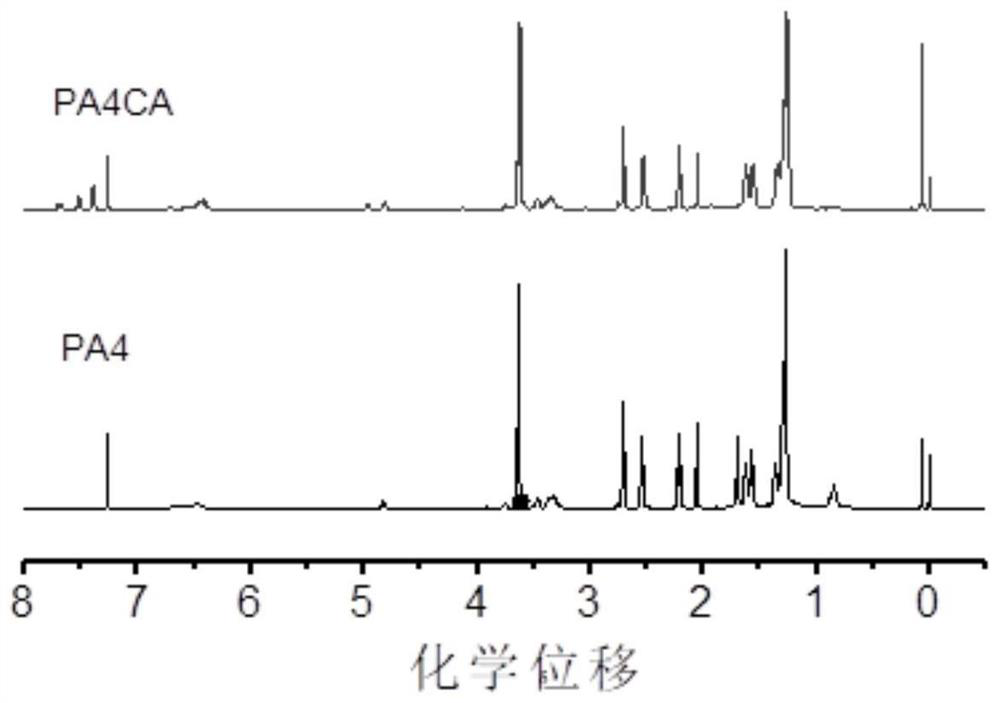

[0057] The structural formula of the castor oil-based functional polyamide synthesized in the present embodiment is as follows:

[0058]

[0059] , where R 2 for -OH or The structural formula of functional polyamide monomer 1 in the present embodiment is: It is the functional polyamide monomer in Example 1-1 disclosed by the patent publication No. CN107501116 A.

[0060] The structural formula of functional polyamide monomer 2 in the present embodiment is: It is the functional polyamide monomer in Example 3 disclosed by the patent pu...

Embodiment 2

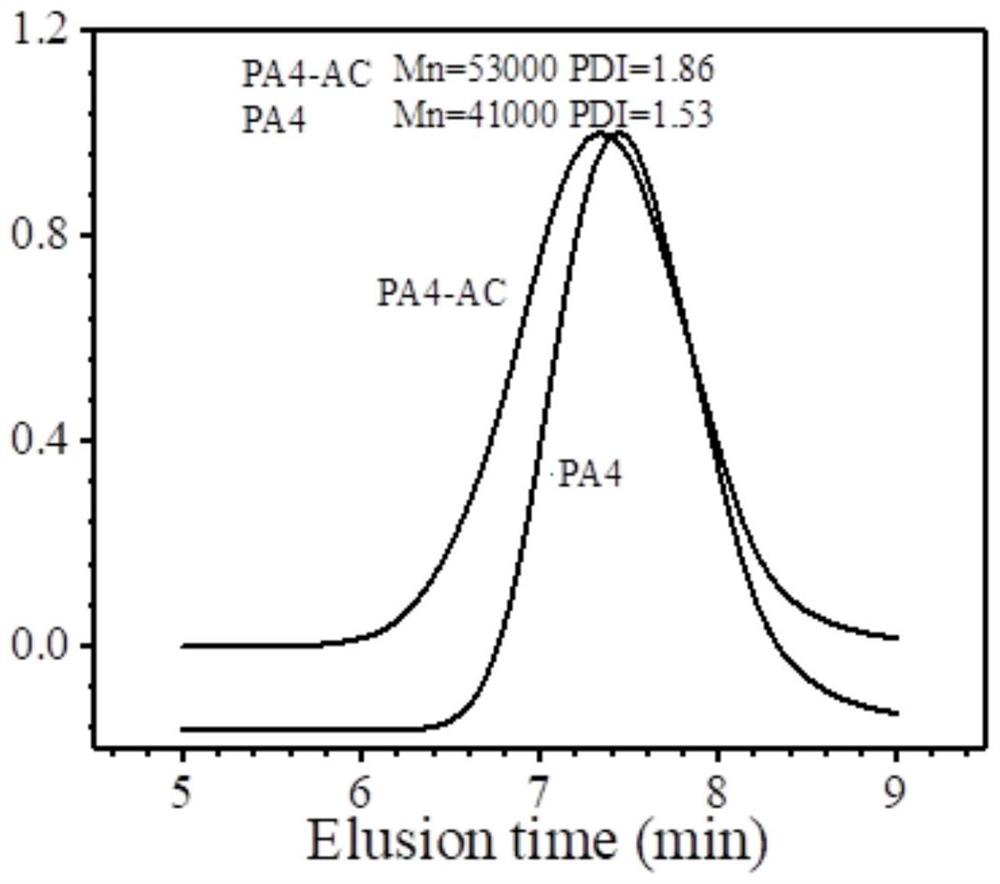

[0062] The preparation method of the castor oil-based polyamide that can be crosslinked by ultraviolet light, the preparation route is as follows figure 1 As shown, the reaction molar ratio -OH:-COOH:DCC:DMAP=1:2:2:0.01, specifically includes the following steps:

[0063] 1) Put 6.296g of castor oil-based elastomer and 1.812g of cinnamic acid in a 50mL round bottom flask, add 15mL of tetrahydrofuran (THF) to mix, and dissolve completely at 65°C;

[0064] 2) Dissolve 50 mg of dimethylaminopyridine (DMAP) in 500 μL of THF solution, add it to the round bottom flask of step (1), weigh 1 g of dicyclohexylcarbodiimide (DCC) and dissolve it in 4.5 mL of THF solution, add In the round bottom flask of step 1). The round bottom flask was sealed. React at 65°C for 12h. The reactant was purified in ethyl acetate to obtain a UV-crosslinkable castor oil-based polyamide.

Embodiment 3

[0066] The preparation method of castor oil-based photocrosslinked polyamide elastomer comprises the following steps:

[0067] Take 1 g of the UV-crosslinkable castor oil-based polyamide in Example 2 into a 20 mL sample bottle, add 10 mL of THF, heat until completely dissolved, place it in a UV light box, and irradiate with a 365 nm UV lamp for 0.5 h to obtain castor oil-based polyamide. Photocrosslinkable polyamide elastomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture stress | aaaaa | aaaaa |

| Fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com