Polyimide nano particle as well as preparation method and application thereof

A technology of polyimide and nanoparticles, applied in textiles and papermaking, single-component synthetic polymer rayon, fiber chemical characteristics, etc., can solve problems such as insufficient compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

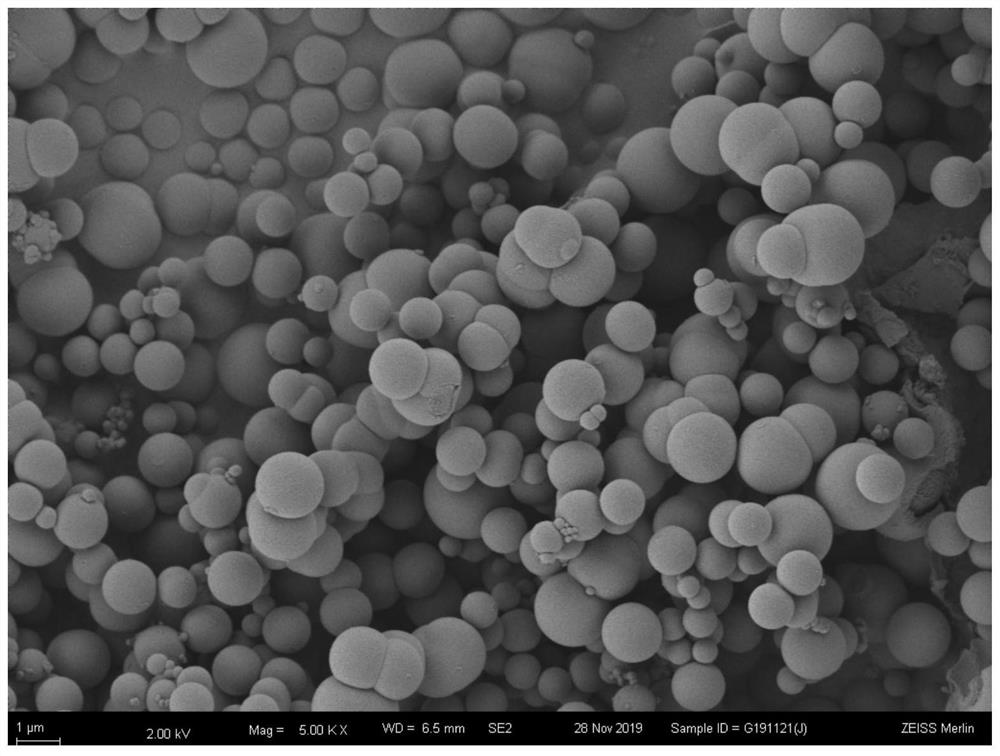

[0077] 1. The 2.00g homophthalic anhydride (9.16mmol) was dispersed into 98.00g of water, and the heating solution temperature was stirred to 80 °C for 2h until the monomer was completely dissolved, at which time the solution was given an aqueous solution of homophthalic acid.

[0078] 2. 1.51g tri(4-aminophenyl)amine (5.19mmol) and 0.21g 3,5-diaminobenzoic acid (1.38mmol) dissolved in water, to be dissolved and dispersed, slowly added to the homophenylenetetracarboxylic acid solution to form a salt, stirred to obtain a powder solid, select ethanol solvent for cleaning and filtration, vacuum drying to obtain a salt monomer composed of acid and amine composite.

[0079] 3. Disperse 1.00g of salt into 99.00g of water, then transfer it to a hydrothermal reactor with stirring, set the reaction temperature to 180 °C, stirring the reaction for 6h.

[0080]4. The product is dispersed into water / ethanol solution for cleaning, filtering, and gradually replacing the water / ethanol solution ...

Embodiment 2

[0084] 1. As in Step 1 of Example 1, a homophthalic acid solution is obtained.

[0085] 2. 0.68g of 1,3,5,7-tetraaminoadamantane (3.44mmol) and 0.35g of 3,5-diaminobenzoic acid (2.29mmol) dispersed in ethanol solution, to be dissolved and dispersed, slowly added to the homophthalic acid solution to form a salt, stirred to obtain a powder solid, select an ethanol solvent for cleaning and filtration, vacuum drying to obtain a salt monomer composed of acid and amine compound.

[0086] 3. Perform a hydrothermal reaction as in step 3 of Example 1.

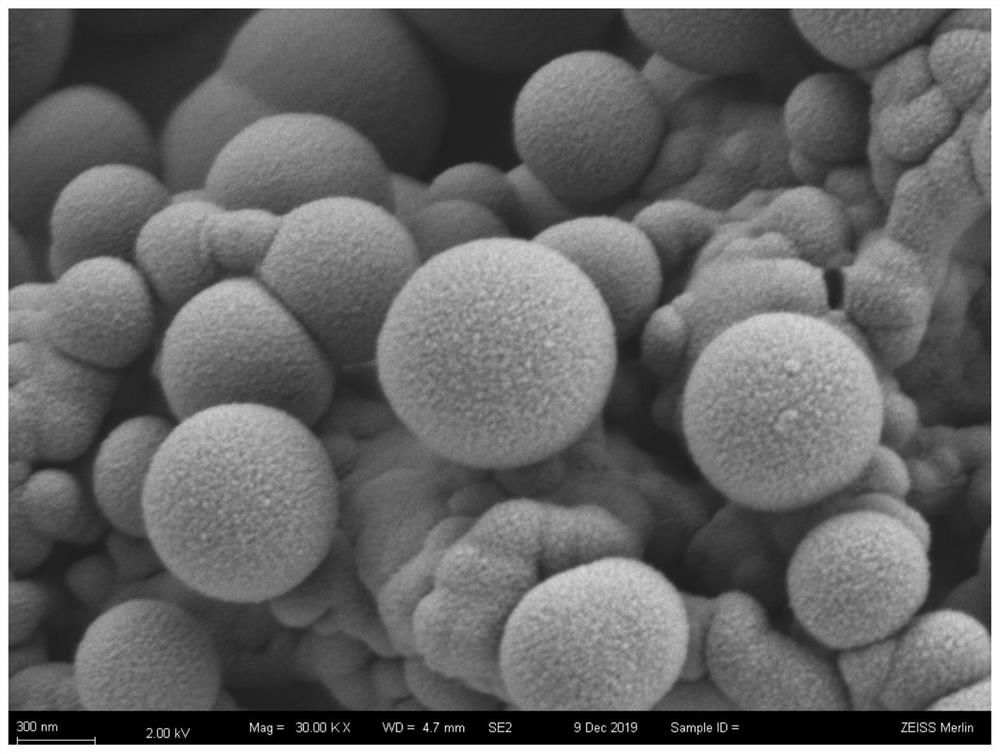

[0087] 4. As in step 4 of Example 1, the sample is cleaned and dried, and the spherical nanoparticles with a size distribution of 0.1~ 0.5 μm are obtained by electron microscopy, such as Figure 2 as shown.

[0088] 5. As in step 5 of Example 1, the blend coating film is carried out, and a polyimide composite film is prepared.

[0089] 6. After the polyimide composite film is modified, the surface wettability is improved, the contact angle o...

Embodiment 3

[0091] 1.00g of homophthalicarboxylic dianhydride (4.58mmol) and 1.35g of 3,3,4,4-biphenyltetracarboxylic dianhydride (4.58mmol) dispersed into 97.65g of water, heated solution temperature to 80 °C stirred for 4h reaction, added 10g ethanol, so that the two tetraic acid monomers completely dissolved in solution.

[0092] 2. 1.51g tri(4-aminophenyl)amine (5.19mmol) and 0.21g 3,5-diaminobenzoic acid (1.38mmol) dissolved in water, to be dissolved and dispersed, slowly added to the homophenylenetetracarboxylic acid solution to form a salt, stirred to obtain a powder solid, select ethanol solvent for cleaning and filtration, vacuum drying to obtain a salt monomer composed of acid and amine composite.

[0093] 3. Perform a hydrothermal reaction as in step 3 of Example 1.

[0094] 4. As in step 4 of Example 1, the sample is cleaned and dried, and the spherical nanoparticles with a size distribution of 2 to 4 μm are obtained by electron microscopy characterization statistics.

[0095] 5. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com