Cyclodextrin-based metal organic framework composite material as well as preparation method and application thereof

A metal-organic framework, organic framework technology, applied in electrochemical generators, coatings, electrical components, etc., can solve the problems of dangerous operation, poor electrochemical performance, etc., and achieve low cost, high porosity, and superior mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

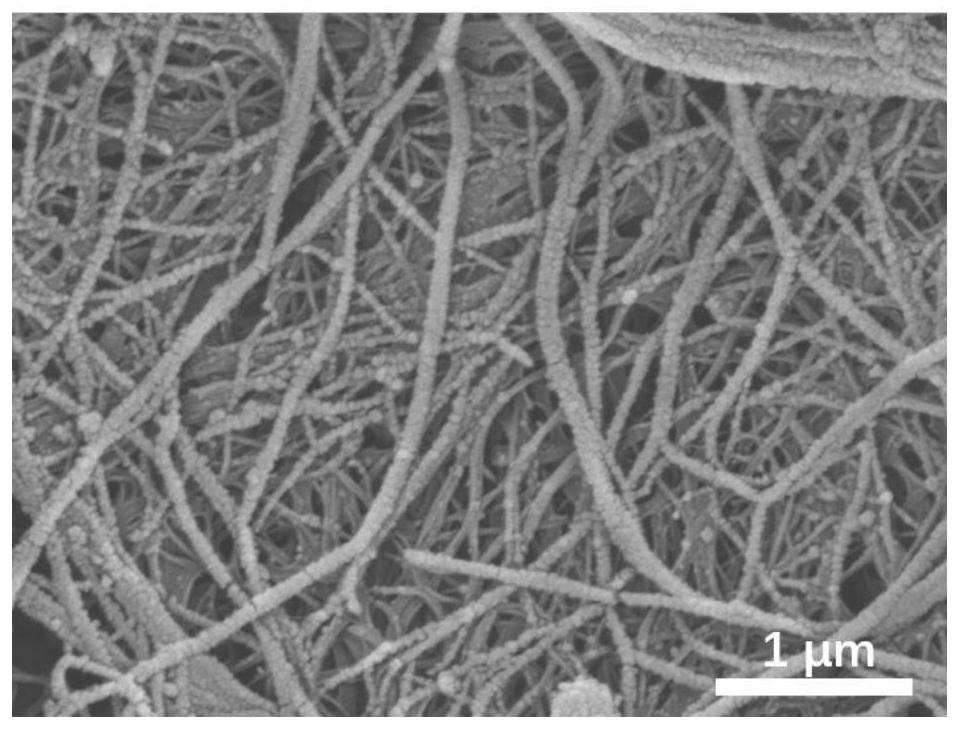

[0032] Step 1: Preparation of cellulose matrix: use commercially available bacterial cellulose, cut into small pieces about 3*3cm in size, soak in 3wt.% NaOH solution, heat to 80°C, stir for 12h, wash to remove residual impurities, Wash with deionized water several times until PH ≈ 7, use a crusher for mechanical crushing, disperse in deionized water, the mass concentration of bacterial cellulose is 1.7mg / mL, suction filter to form a film, pre-freeze, and freeze in a freeze dryer Let dry for 24 hours.

[0033] Step 2: Preparation of Mg metal-organic framework Mg-β-CD-MOF composite cellulose membrane: Weigh 0.203g of magnesium chloride hexahydrate and dissolve it in 10ml of deionized water, dissolve it fully by ultrasonication for 5min at 25°C, and weigh 1.984g of β-cyclopaste Add the essence to the above solution, dissolve it fully by ultrasonication for 5 minutes at 25°C, filter it into a 50mL beaker with a needle filter with a pore size of 0.45μm, immerse the cellulose membr...

Embodiment 2

[0036] Step 1: Preparation of cellulose matrix: use commercially available bacterial cellulose, cut into small pieces about 3*3cm in size, soak in 20wt.% NaOH solution, heat to 80°C, stir for 12h, wash to remove residual impurities, Wash with deionized water several times until PH ≈ 7, use a crusher for mechanical crushing, disperse in deionized water, the mass concentration of bacterial cellulose is 20mg / mL, suction filter to form a film, pre-freeze, and dry in a freeze dryer 24 hours.

[0037] Step 2: Preparation of K metal-organic framework K-γ-CD-MOF composite cellulose membrane: Weigh 0.345g of potassium carbonate and dissolve it in 10mL of deionized water, dissolve it fully by ultrasonication for 5min at 25°C, and weigh 0.162g of γ-cyclodextrin Add it to the above solution, dissolve it fully by ultrasonication for 5 minutes at 25°C, filter it into a 50mL beaker with a needle filter with a pore size of 0.45μm, immerse the cellulose membrane in it, put it into another 200m...

Embodiment 3

[0040] Step 1: Preparation of cellulose matrix: use commercially available bacterial cellulose, cut into small pieces about 3*3cm in size, soak in 5wt.% NaOH solution, heat to 80°C, stir for 12h, wash to remove residual impurities, Wash with deionized water several times to PH ≈ 7, use a crusher for mechanical crushing, disperse in deionized water, the mass concentration of bacterial cellulose is 7.1mg / mL, transfer 5ml dispersion liquid to the mold, pre-freeze, in Dry in a freeze dryer for 48 hours.

[0041] Step 2: Preparation of Na metal-organic framework Na-γ-CD-MOF composite cellulose membrane: Weigh 0.02g of sodium hydroxide and 1.296g of γ-cyclodextrin and dissolve them in 5mL of deionized water, and dissolve them fully by ultrasonication for 5min at 25°C , mix, filter into a 50mL beaker with a needle filter with a pore size of 0.45μm, immerse the cellulose airgel in it, put it into another 200mL beaker filled with 40mL of absolute ethanol, seal the container, and react ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com