ABS (Acrylonitrile Butadiene Styrene) resin composite antioxidant and preparation method thereof

A composite antioxidant and ABS resin technology, applied in the field of antioxidants, can solve the problem of single composition and function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

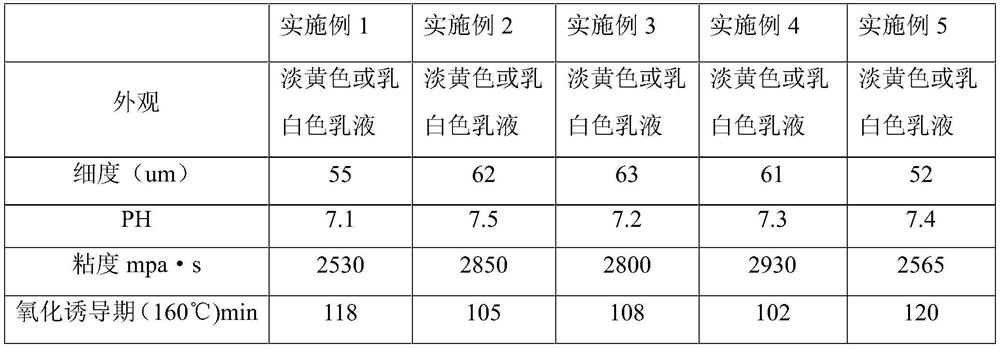

Examples

Embodiment 1

[0021] Pour 57.5g of measured deionized water into the dispersion tank and start stirring at a low speed, slowly add 0.85g of light stabilizer 5411 weighed to dissolve, and then add 0.65g of polyacrylic acid after it is completely dissolved Stir the methyl ester for 20 minutes, then slowly add 5.5g of zinc stearate weighed, after the zinc stearate is completely dissolved, slowly add 23.5g of antioxidant WL and 12.0g of antioxidant 3052 respectively Increase the stirring speed and stir vigorously for about 10 minutes, then reduce the speed and continue stirring for 30 minutes to obtain a preliminary dispersion. After the preliminary dispersion is ground by a sand mill and then filtered through a filter, it is the required ABS resin composite antioxidant.

Embodiment 2

[0023] Pour 53.0g of measured deionized water into the dispersion tank and start stirring at a low speed, slowly add 1.2g of light stabilizer 770 weighed to dissolve, and then add 0.3g of silicone oil weighed and stir After 10 minutes, slowly add 5.5g of the weighed glycol fatty acid ester, and slowly add the weighed antioxidant WL 25.5g and antioxidant 3052 14.5g after the glycol fatty acid ester is completely dissolved Then increase the stirring speed and stir vigorously for about 5 minutes, then reduce the speed and continue stirring for 20 minutes to obtain a preliminary dispersion. After the preliminary dispersion is ground by a sand mill and then filtered through a filter screen, it is the required ABS resin composite antioxidant. .

Embodiment 3

[0025] Pour 55.5g of measured deionized water into the dispersion tank and start stirring at a low speed, slowly add 0.8g of light stabilizer 5411 weighed to dissolve, and then add 0.2g of palmitic acid after it is completely dissolved After the isopropyl ester is stirred for 30 minutes, slowly add 5.5g of dipentaerythritol ester that has been weighed. After the dipentaerythritol ester is completely dissolved, slowly add 22.5g of antioxidant WL and 15.5g of antioxidant 3052 respectively, and then speed up. Stir vigorously at the stirring speed for about 15 minutes, then reduce the rotating speed and continue stirring for 40 minutes to obtain a preliminary dispersion. After the preliminary dispersion is ground by a sand mill and then filtered through a filter screen, it is the required ABS resin composite antioxidant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com