Antibacterial degradable gas barrier material and preparation method thereof

A technology of gas barrier and degradable materials, which is applied in the field of antibacterial and degradable gas barrier materials and its preparation, can solve the problems of difficulty in meeting the performance requirements of plastic film moisture retention, difficulty in meeting food preservation requirements, weakening gas barrier properties, etc., and achieve easy batch production The chemical production, the preparation method are simple and convenient, and the effect of improving the gas barrier property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

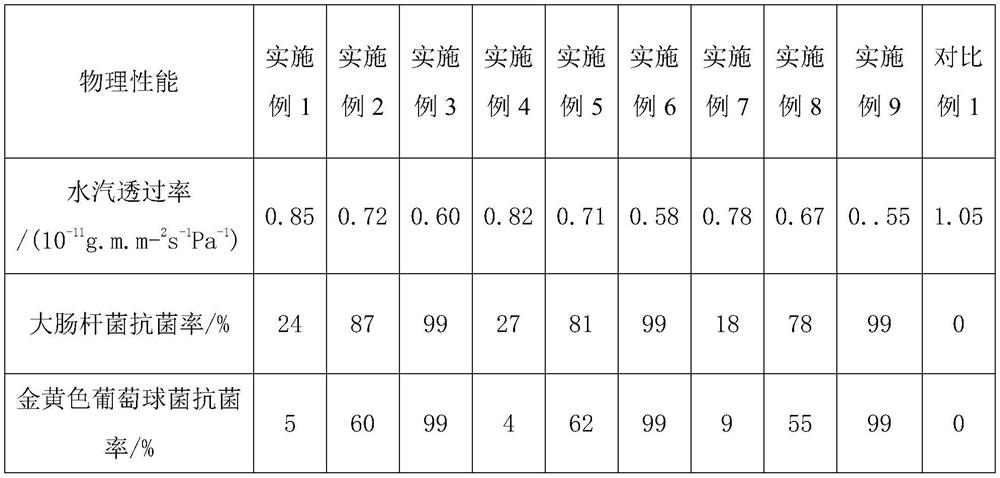

Examples

Embodiment 1

[0023] Weigh PBAT 84.45wt%; PLA 10wt%; ionic liquid modified montmorillonite 5wt%; compatibilizer: 0.5wt%; photoinitiator: 0.05wt%. Mix evenly to obtain mixed raw materials.

[0024] The above-mentioned mixed raw materials are placed in the main feeding bin of the intermeshing co-rotating twin-screw extruder, and are added into the barrel of the extruder through the feeding screw. D is 40, the temperature of each zone of the main cylinder from the feeding port to the outlet of the machine head is set as: 140°C, 140°C, 140°C, 150°C, 150°C, 160°C, 160°C, and the speed of the main engine is 200-300 rpm Minutes, through melt extrusion, cooling, granulation, and drying, an antibacterial and degradable material with good gas barrier properties is obtained.

[0025] The above-mentioned degradable materials are blow molded on a film blowing machine, the blow molding temperature is 140°C, and the film thickness is 30-50 μm. The blown film material is irradiated with ultraviolet light...

Embodiment 2

[0029] Weigh PBAT 79.45wt%; PLA 10wt%; ionic liquid modified montmorillonite 10wt%; compatibilizer: 0.5wt%; photoinitiator: 0.05wt%. Mix evenly to obtain mixed raw materials.

[0030] The above-mentioned mixed raw materials are placed in the main feeding bin of the intermeshing co-rotating twin-screw extruder, and are added into the barrel of the extruder through the feeding screw. D is 40, the temperature of each zone of the main cylinder from the feeding port to the outlet of the machine head is set as: 140°C, 140°C, 140°C, 150°C, 150°C, 160°C, 160°C, and the speed of the main engine is 200-300 rpm Minutes, through melt extrusion, cooling, granulation, and drying, an antibacterial and degradable material with good gas barrier properties is obtained.

[0031] The above-mentioned degradable materials are blow molded on a film blowing machine, the blow molding temperature is 140°C, and the film thickness is 30-50 μm. The blown film material is irradiated with ultraviolet ligh...

Embodiment 3

[0035] Weigh PBAT 69.45wt%; PLA 10wt%; ionic liquid modified montmorillonite 20wt%; compatibilizer: 0.5wt%; photoinitiator: 0.05wt%. Mix evenly to obtain mixed raw materials.

[0036] The above-mentioned mixed raw materials are placed in the main feeding bin of the intermeshing co-rotating twin-screw extruder, and are added into the barrel of the extruder through the feeding screw. D is 40, the temperature of each zone of the main cylinder from the feeding port to the outlet of the machine head is set as: 140°C, 140°C, 140°C, 150°C, 150°C, 160°C, 160°C, and the speed of the main engine is 200-300 rpm Minutes, through melt extrusion, cooling, granulation, and drying, an antibacterial and degradable material with good gas barrier properties is obtained.

[0037] The above-mentioned degradable materials are blow molded on a film blowing machine, the blow molding temperature is 140°C, and the film thickness is 30-50 μm. The blown film material is irradiated with ultraviolet ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com