Diesel oil pour point depressant containing allyl phenyl ether as well as preparation method and application of diesel oil pour point depressant

A technology of allyl phenyl ether and diesel pour point depressant, which is used in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve problems such as affecting the normal use of diesel oil, blocking diesel engine filters, etc., to improve the pour point depressant effect. , The effect of improving cold flow and solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

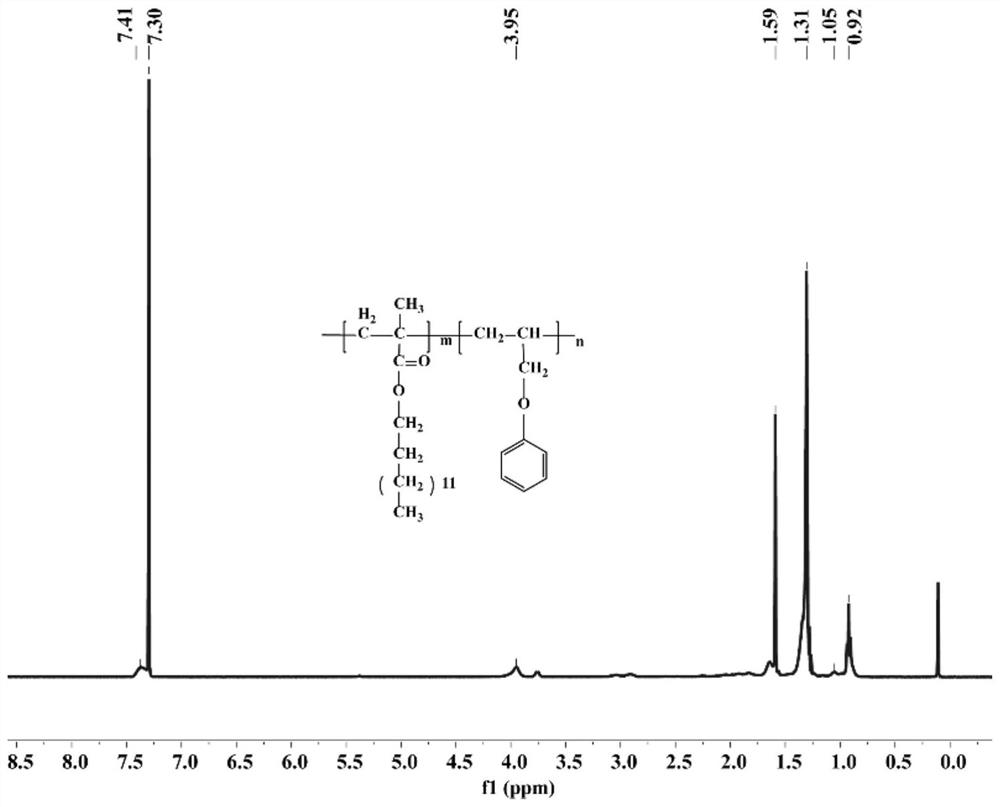

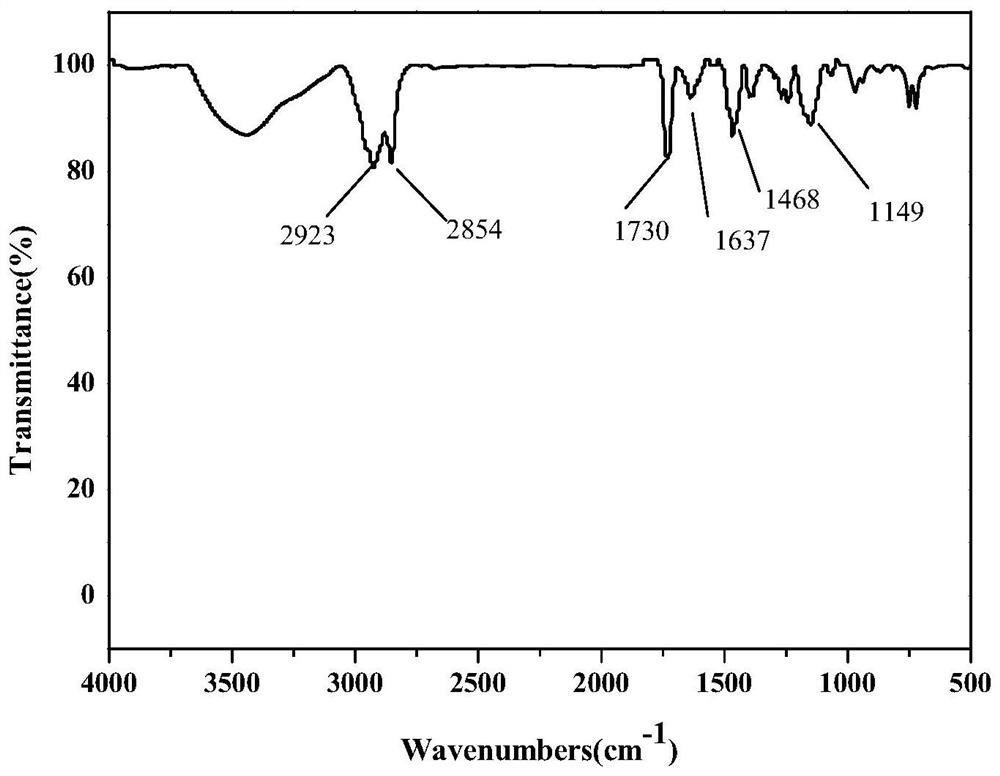

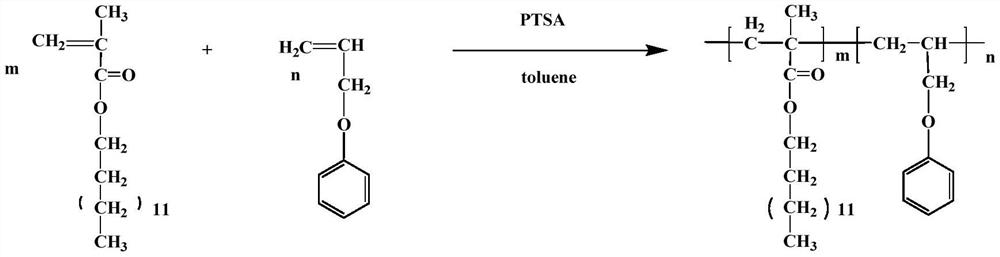

[0029] A diesel decoagulant containing allyl phenyl ether, the preparation method comprising the following steps:

[0030] 1) Preparation of tetradeteryl methacrylate:

[0031] The methacrylic acid and tetradecanol were added to toluene in a molar ratio of 1.2:1, and then the polymerization inhibitor p-benzenediol was added to the catalyst p-toluenesulfonic acid, heated and stirred until the solid was dissolved, and then pre-reacted at 90 ° C for 1h; then heated to 100-120 ° C, and the esterification reaction was carried out for 4-6 hours to obtain the reaction mixture; The amount of hydrophenol is 0.56-0.63% of the total mass of methacrylic acid and tetradecyl alcohol, and the amount of p-toluenesulfonic acid is 1.1-1.3% of the total mass of methacryl acid and tetradecyl alcohol;

[0032] 5wt% NaOH solution was used to wash until the solution was weakly alkaline, and then washed with deionized water to neutral, the organic phase was placed in a steamer for rotational evaporation,...

Embodiment 1

[0040] A phenoxy-containing diesel decoagulant, is made of tetradeceth methacrylate and allyl phenyl ether polymerization, the preparation method comprises the following steps:

[0041] 1) Add tetradecanol (21.44g) and methacrylic acid (10.33g) to the dry and clean three-mouth flask in a molar ratio of 1:1.2, and then move the three-mouth flask to the oil bath pot, install the thermometer, condensing tube, water separator and pass water;

[0042] 2) Add the polymerization inhibitor hydroquinone and catalyst p-toluenesulfonic acid, the amount of tetradecanol and methacrylic acid total mass of 0.6% and 1.2%, respectively, and 40mL reaction solvent toluene, and then heat up to 60 °C to dissolve the solid, and maintain 90 °C for 1 hour of pre-reaction;

[0043] 3) Heat up to 120 °C and react for 6 hours; after the resulting reaction product system is cooled to room temperature, pour into a 250mL separating funnel, wash 3 times with 5wt% NaOH solution to weak alkaline, wash 3 times wit...

Embodiment 2

[0049] A phenoxy-containing diesel deagulant, composed of tetradeceth methacrylate and allyl phenyl ether polymerization, wherein the dosage of tetradeceth methacrylate is 5.65g, the amount of allyl phenyl ether is 0.89g, and the molar ratio of tetradeceth methacrylate to allyl phenyl ether is 3:1. The remainder is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com