Multi-layer rendering method for art cloth

A multi-layer rendering and cloth technology, applied in the field of cloth rendering, can solve the problems of cloth drying loss, environmental protection, color mixing, etc., to achieve the effect of improving stability, ensuring aesthetics, and improving adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

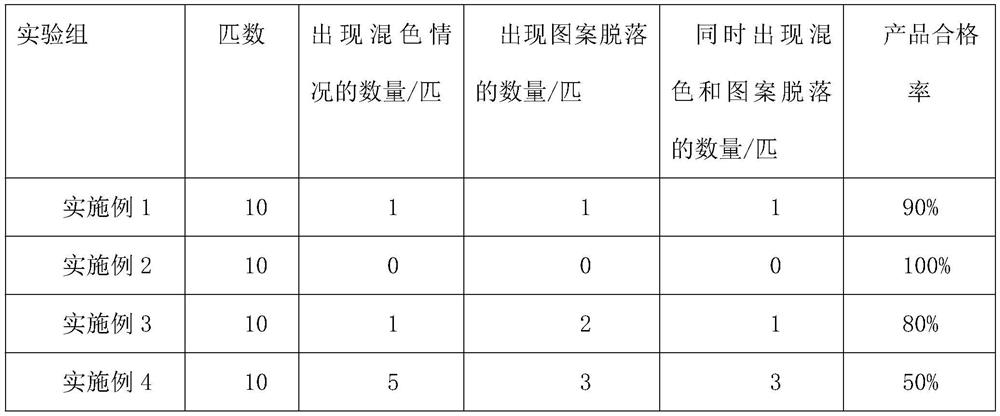

Examples

Embodiment 1

[0018] A multi-layer rendering method for artistic cloth, the specific rendering method is as follows:

[0019] Step 1, cloth pretreatment operation: Put the cloth to be rendered into the mixing container and inject the treatment solution at 100°C, the stirring speed is controlled at 300 rpm, and the stirring time is controlled at 30 minutes for pretreatment, among which the treatment solution is Contains 0.8g / L of scouring agent, 1.2g / L of adhesion enhancer and 3.5g / L of sodium hydroxide. After the above stirring is completed, the treated cloth is placed at 80°C for boiling treatment, and then at 20°C Wash with water, then pickle in 0.5g / L acetic acid solution;

[0020] Step 2, layered dye injection operation: a. Put the pretreated cloth into deionized water, add wetting agent and vat dye, stir until even after heating up, and then cool down to obtain dye liquor;

[0021] b. Soak the cloth in a container and perform singeing, desizing and mercerizing to obtain the treated cl...

Embodiment 2

[0029] A multi-layer rendering method for artistic cloth, the specific rendering method is as follows:

[0030] Step 1, cloth pretreatment operation: Put the cloth to be rendered into the mixing container and inject the treatment liquid at 110°C, the stirring speed is controlled at 400 rpm, the stirring time is controlled at 40 minutes, and the pretreatment is carried out, among which the treatment liquid is Contains 1.5g / L scouring agent, 1.6g / L adhesion enhancer and 4g / L sodium hydroxide. After the above stirring is completed, the treated cloth is boiled at 90°C, and then washed at 25°C. , then pickling in 0.7g / L acetic acid solution;

[0031] Step 2, layered dye injection operation: a. Put the pretreated cloth into deionized water, add wetting agent and vat dye, stir until even after heating up, and then cool down to obtain dye liquor;

[0032] b. Soak the cloth in a container and perform singeing, desizing and mercerizing to obtain the treated cloth;

[0033] c. Put the ...

Embodiment 3

[0040] A multi-layer rendering method for artistic cloth, the specific rendering method is as follows:

[0041] Step 1, cloth pretreatment operation: Put the cloth to be rendered into the mixing container and inject the treatment liquid at 120°C, the stirring speed is controlled at 450 rpm, and the stirring time is controlled at 50 minutes for pretreatment, among which the treatment liquid is Contain 2.5g / L scouring agent, 2g / L adhesion enhancer and 5g / L sodium hydroxide. After the above stirring is completed, place the treated cloth at 100°C for boiling treatment, then wash it with water at 30°C, and then Pickling in 1g / L acetic acid solution;

[0042] Step 2, layered dye injection operation: a. Put the pretreated cloth into deionized water, add wetting agent and vat dye, stir until even after heating up, and then cool down to obtain dye liquor;

[0043] b. Soak the cloth in a container and perform singeing, desizing and mercerizing to obtain the treated cloth;

[0044] c. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com