Electrochemical dyestuff dyeing device and method

The technology of a dyeing device and dyeing method, which is applied in the field of electrochemical dyeing devices, can solve the problems of unfavorable production, high price, and short service life of ion exchange membranes, so as to improve production efficiency, realize recycling, and accelerate the electrochemical reduction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

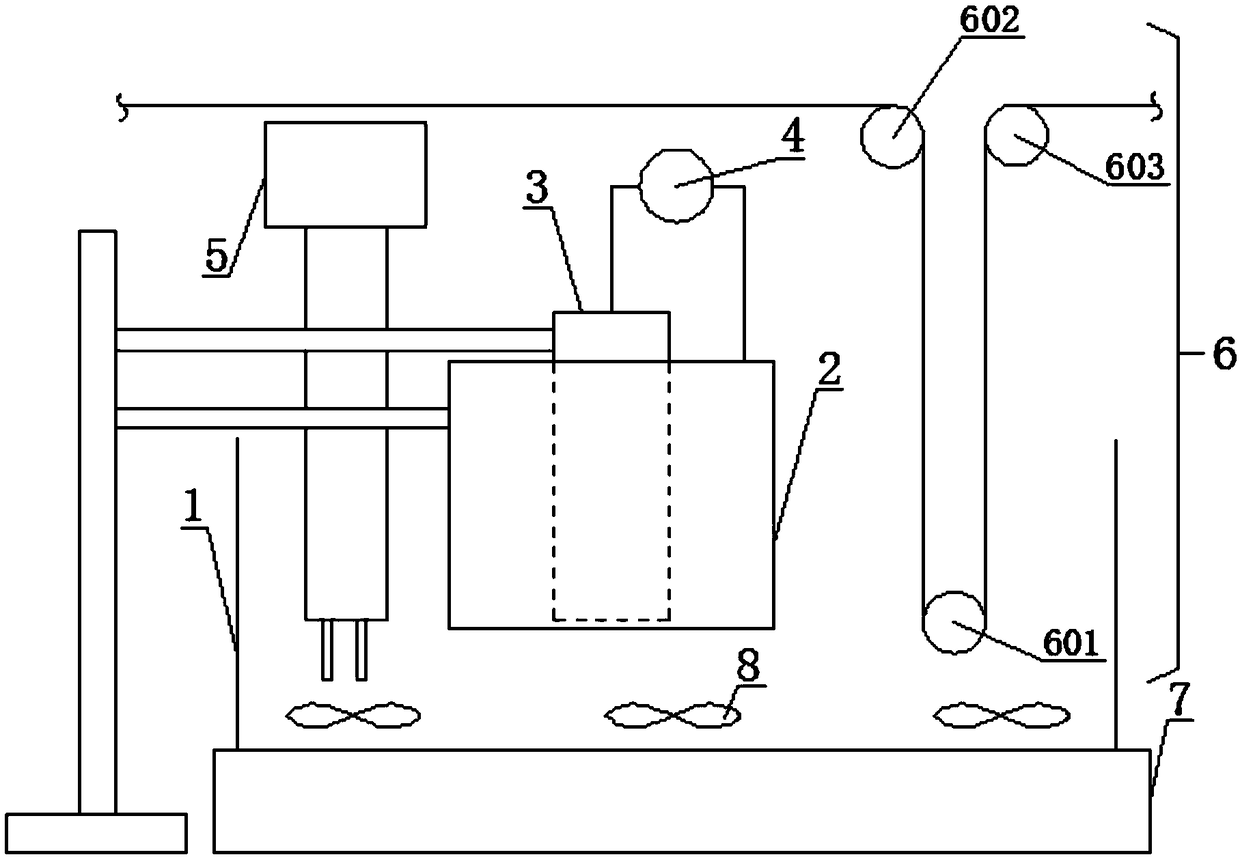

Image

Examples

Embodiment 1

[0052] In 4g / L sodium hydroxide aqueous solution, add 5g / L sodium sulfate, 0.02mol / L triethanolamine, 1.5g sulfide blue in turn and stir thoroughly to obtain an electrolyte, which is added to the electrolytic cell of the electrochemical dye dyeing device The reduction is carried out in the medium, the cathode is a graphene / polypyrrole composite material, the anode is a graphene / polypyrrole composite material, the electrolytic reduction temperature is 60 ° C, the electrolytic current density is 0.15 A / dm2, and the electrolyte is completely reduced to a reducing solution , turn on the roller mechanism to dye the yarn, and then energize and restore for 0.5 hour, and the measured current efficiency is 75.4%.

Embodiment 2

[0054] In 4g / L sodium hydroxide aqueous solution, add 5g / L sodium sulfate, 0.06mol / L triethanolamine, 1.8g sulfur red in sequence and stir thoroughly to obtain an electrolyte, which is added to the electrolysis of the same electrochemical dyeing device Reduction in the pool, the cathode graphene / polypyrrole composite material, the anode carbon nanotube / polyphenylene vinylene composite material, the electrolytic reduction temperature is 60 ° C, the electrolytic current density is 0.4 A / dm2, and the electrolyte is completely reduced to For reducing solution, turn on the roller mechanism to dye the yarn, and then energize and reduce for 0.5 hours, and the measured current efficiency is 80.3%.

Embodiment 3

[0056] Add 5g / L iron sulfate, 0.1mol / L triethanolamine, and 2g sulfur black in 4g / L sodium hydroxide aqueous solution, and stir thoroughly to obtain an electrolyte, which is then added to the electrolytic cell of the same electrochemical dye dyeing device The reduction is carried out in the medium, the cathode is carbon nanotube / polyphenylene acetylene composite material, the anode is carbon nanotube / polyphenylene acetylene composite material, the electrolytic reduction temperature is 60 ℃, the electrolytic current density is 0.25 ampere / square decimeter, and the electrolyte is completely Reduce to reducing solution, turn on the roller mechanism to dye the yarn, and then energize and reduce for 0.5 hours, the measured current efficiency is 71.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com