System for increasing proportion of organic waste co-processed by cement kiln and processing method

A technology for organic waste and co-processing, applied in separation methods, combustion methods, chemical instruments and methods, etc., can solve the problems of insufficient disposal of organic waste, slow response of adjustment speed, and high temperature of tertiary air, and reduce auxiliary fuels. The effect of consumption, increase of organic waste, and reduction of negative impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

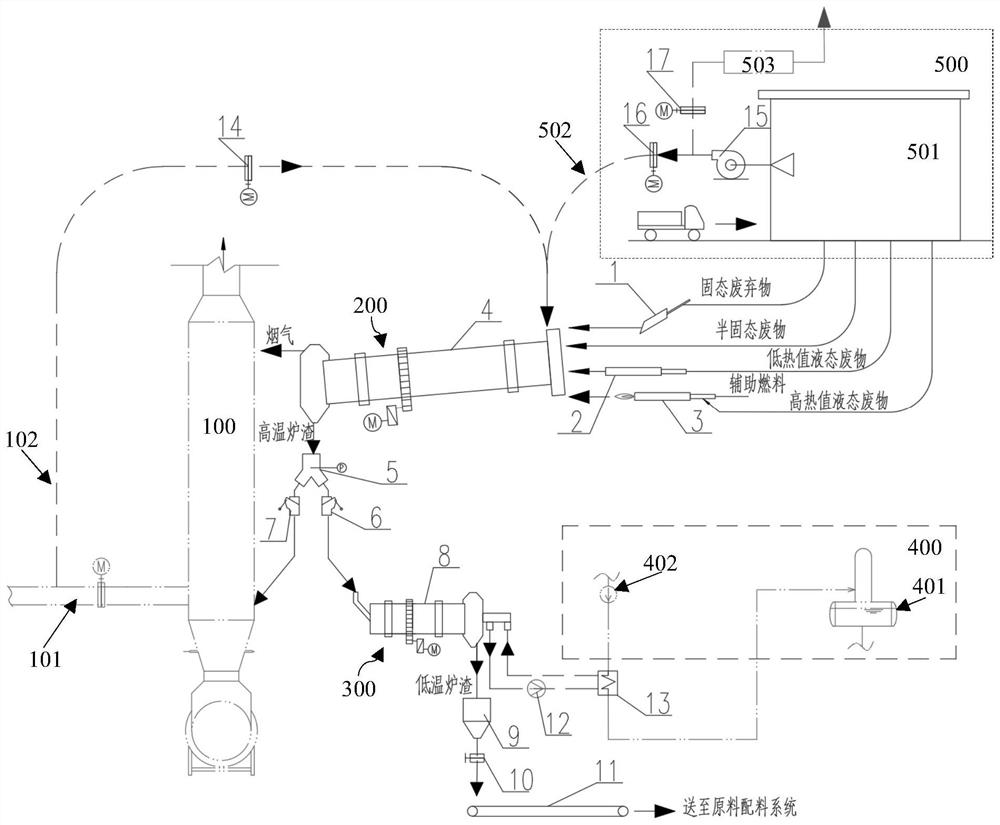

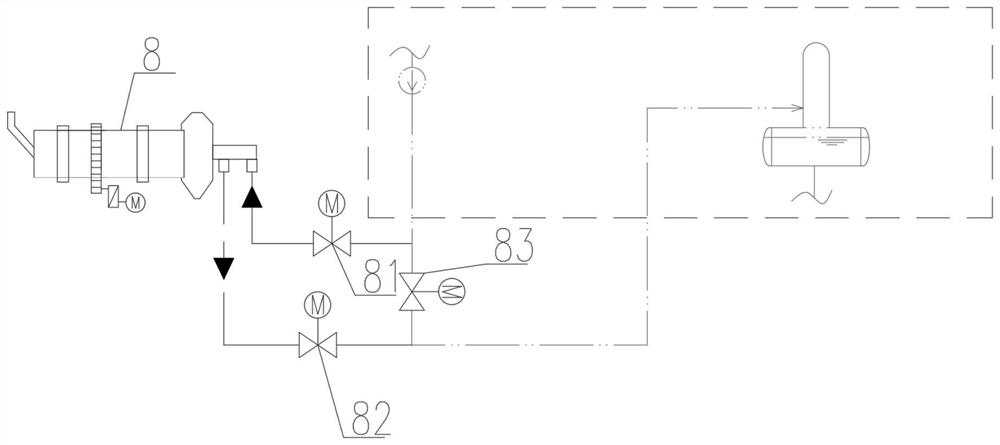

[0024] Embodiment 1: as figure 1 As shown, the system for increasing the proportion of organic waste in the co-processing of cement kilns according to the present invention includes a calciner 100, a tertiary air duct 101 connected to the calciner 100, a high-temperature pre-treatment system 200, a residue cooling and conveying system 300, and waste heat power generation System 400 and waste pretreatment system 500. The high-temperature pre-treatment system 200 includes a sealed feeding device 1, a waste liquid spray gun 2, a burner 3, and a multi-phase waste pre-combustion furnace 4. The waste outlet of the multi-phase waste pre-combustion furnace 4 is connected to the material distribution device 5, The outlet of the distribution device 5 communicates with the calciner 100 through the first valve 6 and communicates with the residue cooling conveying system 300 through the second valve 7 respectively. The slag cooling conveying system 300 includes a slag cooler 8 , a slag bi...

Embodiment 2

[0032] Example 2: Using the system described in Example 1 to increase the proportion of co-processing organic waste in cement kilns for residue treatment, the residual heat can be recovered and the power generation capacity of the system can be increased.

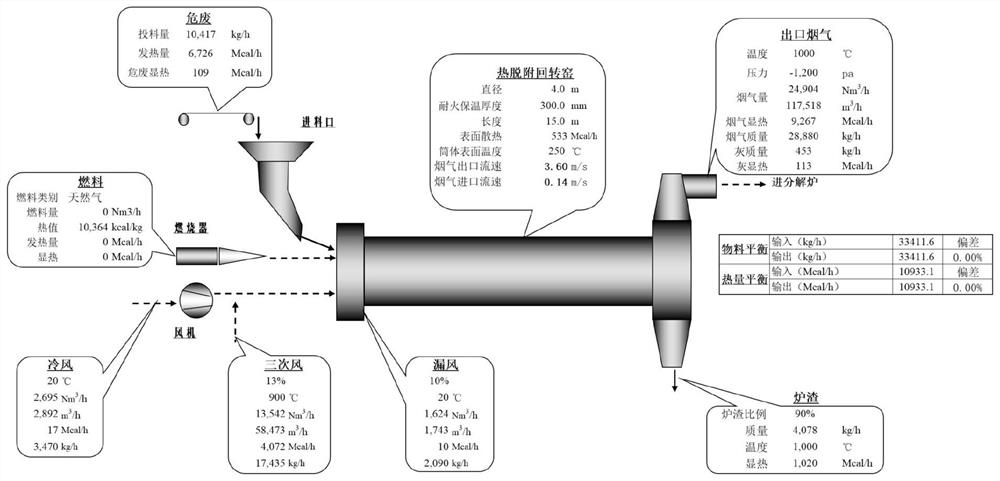

[0033] (1) Calculation of heat balance of high temperature pretreatment system for organic waste disposal

[0034] The calculation uses the tertiary air of the cement production line as part of the combustion air source and heat source, and adjusts the air supply ratio of the tertiary air to ensure that the rotary kiln does not need supplementary combustion. Organic waste with low calorific value (1000kcal / kg) was selected as the research object, and its composition is shown in Table 1.

[0035] Table 1 Elemental composition of organic waste with low calorific value (1000kcal / kg) co-processed in cement kiln

[0036] type C H O N S Cl Water ASH F composition ratio Hazardous Waste 10.00% 2.20% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com