Selenium-doped nickel-cobalt sulfide with cross-linked nanosheet structure and preparation method of selenium-doped nickel-cobalt sulfide

A nickel-cobalt sulfide and selenium doping technology, applied in nickel compounds, chemical instruments and methods, nickel sulfide, etc., can solve nickel-cobalt sulfide low conductivity, slow charge transfer kinetics, and multiple oxidation of charge transfer kinetics Reduce active sites and other issues to achieve the effects of improving electrochemical performance, solving slow reaction kinetics, enhancing electrical conductivity and redox reaction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

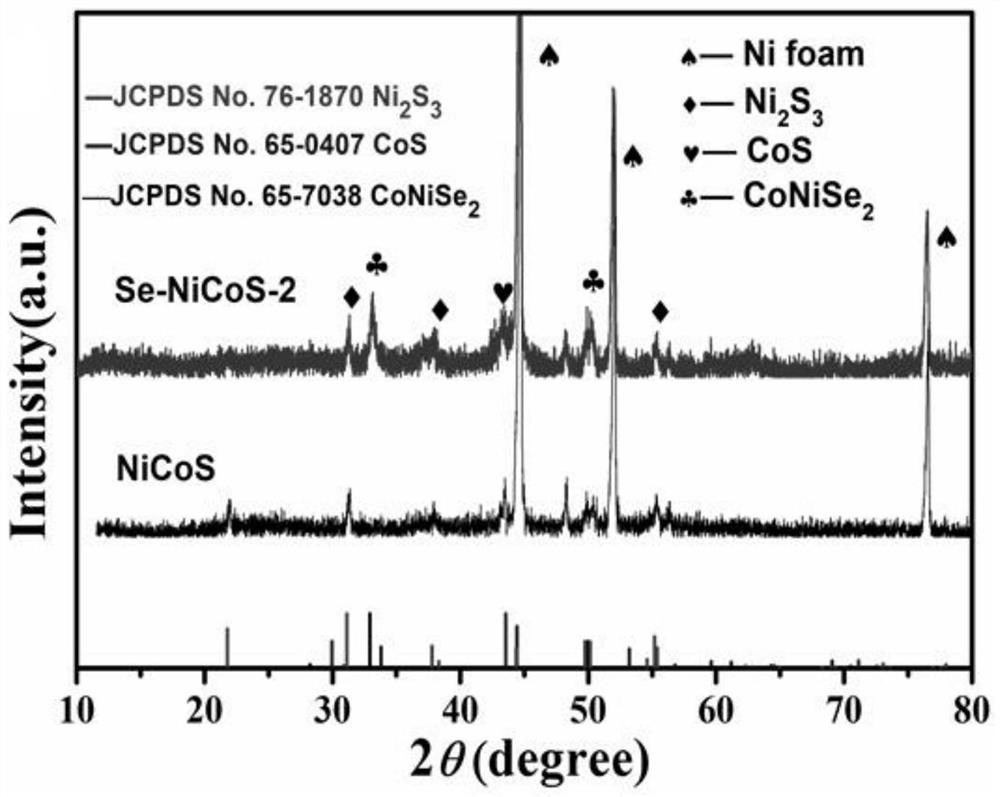

[0042] A method for preparing a selenium-doped nickel-cobalt sulfide electrode material with an intercrosslinked nanosheet structure. Specific steps include:

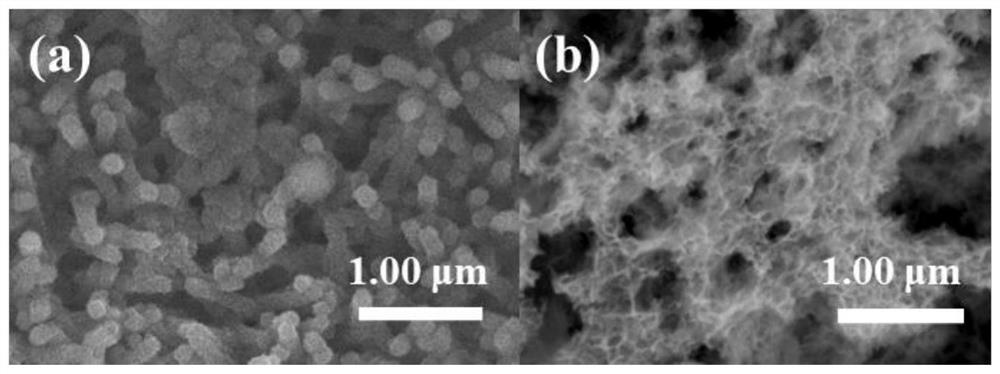

[0043] ① from nickel chloride hexahydrate (NiCl 2 ·6H 2 O), cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) and urea (CO(NH 2 ) 2 ) as a raw material, with a mass ratio of 1:2:2, reacting at a temperature of 120° C. for 8 hours by a hydrothermal method to prepare a nickel-cobalt precursor;

[0044] ② Place the nickel-cobalt precursor synthesized in step ① in a high-pressure reactor containing 50mM sodium sulfide solution, and react at a temperature of 120°C for 10h to carry out ion exchange reaction to obtain nickel-cobalt sulfide (NiCoS);

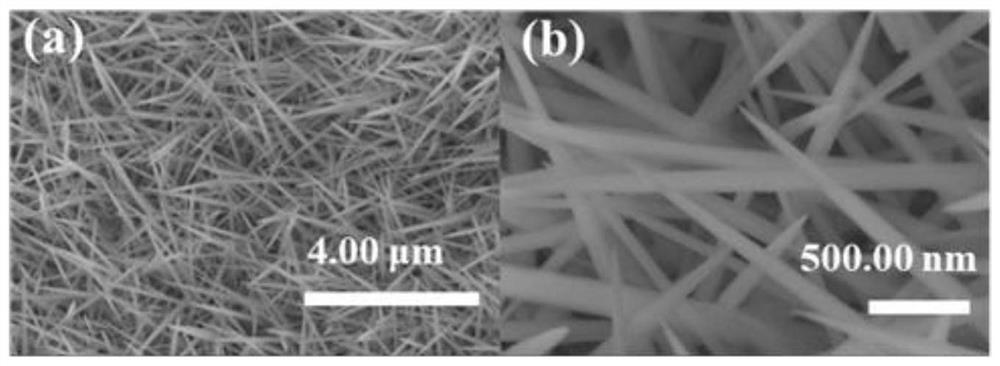

[0045] 3. The nickel-cobalt sulfide of gained is subjected to heat treatment selenization reaction, and the concrete process of heat treatment selenization process is: when nickel-cobalt sulfide and selenium powder are 11:5 by mass (selenium powder introduction amount is 5mg), 35...

Embodiment 2

[0048] The difference between this embodiment and Example 1 is that, for the selenium-doped nickel-cobalt sulfide material, nickel-cobalt sulfide and selenium powder are 11:10 by mass in the heat treatment selenization process (the amount of selenium powder introduced is 10mg).

Embodiment 3

[0050] The difference between this embodiment and Example 1 is that, for the selenium-doped nickel-cobalt sulfide material, nickel-cobalt sulfide and selenium powder are 11:20 by mass in the heat treatment selenization process (the introduction amount of selenium powder is 20mg).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com