Preparation method of PtCo/C intermetallic compound catalyst with high metal content

An intermetallic compound, high metal technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of agglomeration and sintering affecting the performance of catalysts, and achieve the effect of small particle size and excellent catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of the PtCo / C intermetallic compound catalyst of high metal content, specifically comprises the steps:

[0034] (1) Disperse the carbon carrier into an analytically pure ethylene glycol solution, and ultrasonically disperse for 30-60 minutes;

[0035] (2) Dissolve the platinum salt precursor in an analytically pure ethylene glycol solution and sonicate for 10-20min;

[0036] (3) Add the ethylene glycol solution of the platinum salt precursor to the carbon carrier ethylene glycol solution and sonicate for 30-60 minutes, add the alkali-ethylene glycol solution to adjust the pH value to 8-12, and disperse it by ultrasonic for 30-60 minutes;

[0037] (4) Add a reducing agent to the mixed solution obtained in step (3), and stir at room temperature for 30-60min;

[0038] (5) reacting the mixed solution obtained in step (4) in an oil bath in a protective atmosphere, and filtering, washing and drying after the reaction;

[0039] (6) Dissolving the...

Embodiment 1

[0055] A kind of preparation method of high metal content PtCo / C intermetallic compound catalyst, specifically comprises the following steps:

[0056] (1) Disperse 600mg of Vulcan XC-72 carbon powder produced by American Cabot Company in 100ml of ethylene glycol solution, and ultrasonically disperse for half an hour;

[0057] (2) 1.03g of chloroplatinic acid was dissolved in 106ml of analytically pure ethylene glycol solution for ultrasonication for 10 minutes;

[0058] (3) Add the chloroplatinic acid ethylene glycol solution to the Vulcan XC-72 ethylene glycol solution for half an hour, add sodium hydroxide to adjust the pH value to 10, and ultrasonically disperse for 1 hour;

[0059] (4) Add 60 mg of glucose to the mixed solution obtained in step (3), and stir at room temperature for half an hour;

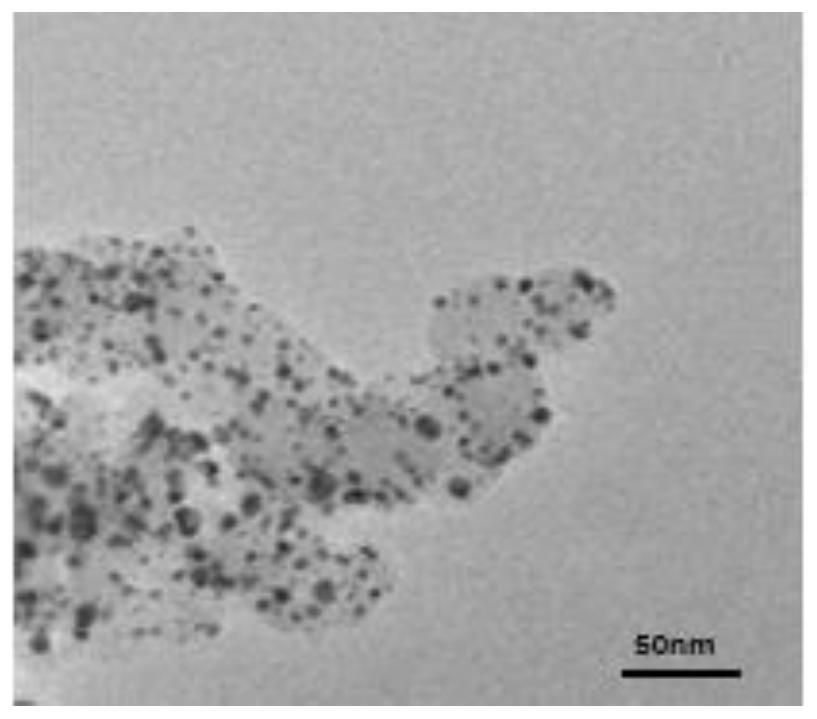

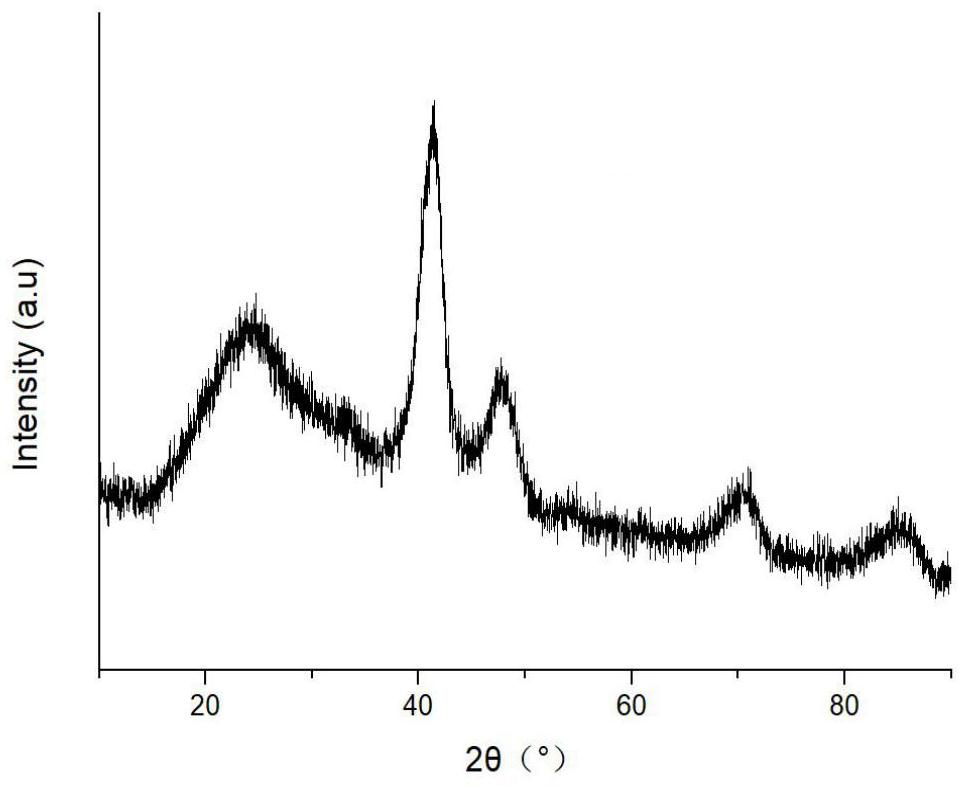

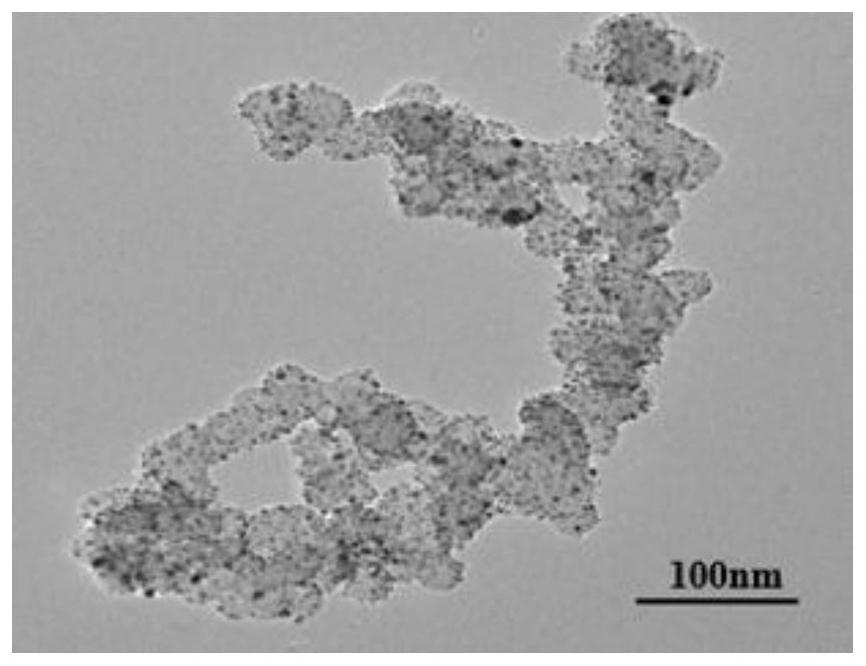

[0060] (5) React the mixed solution obtained in step (4) in an oil bath in an argon atmosphere, the temperature of the oil bath is 150° C., and the reaction time is 4 hours. Aft...

Embodiment 2

[0067] A kind of preparation method of high metal content PtCo / C intermetallic compound catalyst, specifically comprises the following steps:

[0068] (1) Disperse 600mg of Vulcan XC-72 carbon powder produced by American Cabot Company in 100ml of ethylene glycol solution, and ultrasonically disperse for half an hour;

[0069] (2) 1.03g of chloroplatinic acid was dissolved in 106ml of analytically pure ethylene glycol solution for ultrasonication for 10 minutes;

[0070] (3) Add the ethylene glycol solution of the chloroplatinic acid precursor to the Vulcan XC-72 ethylene glycol solution for half an hour, add sodium hydroxide to adjust the pH value to 10, and ultrasonically disperse for 1 hour;

[0071] (4) Add 60 mg of glucose to the mixed solution obtained in step (3), and stir at room temperature for half an hour;

[0072] (5) React the mixed solution obtained in step (4) in an oil bath in an argon atmosphere, the temperature of the oil bath is 150° C., and the reaction tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com