Soybean protein composition with high foamability and foaming stability and preparation method thereof

A soybean protein and composition technology, applied in biochemical equipment and methods, protein composition of vegetable seeds, beer fermentation method, etc., can solve the problems of protein utilization limitation, tediousness, safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

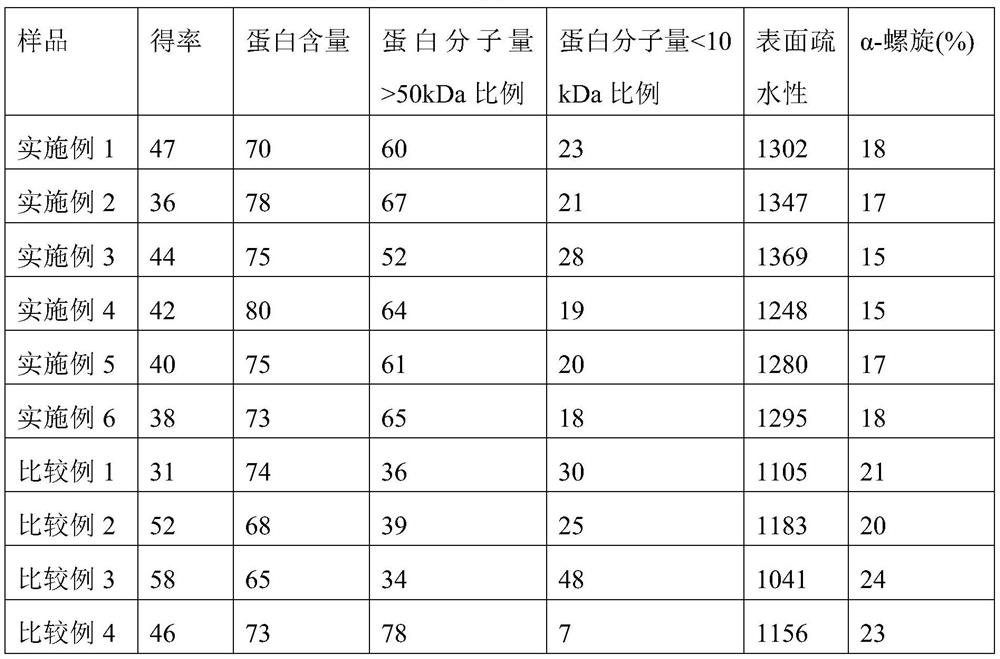

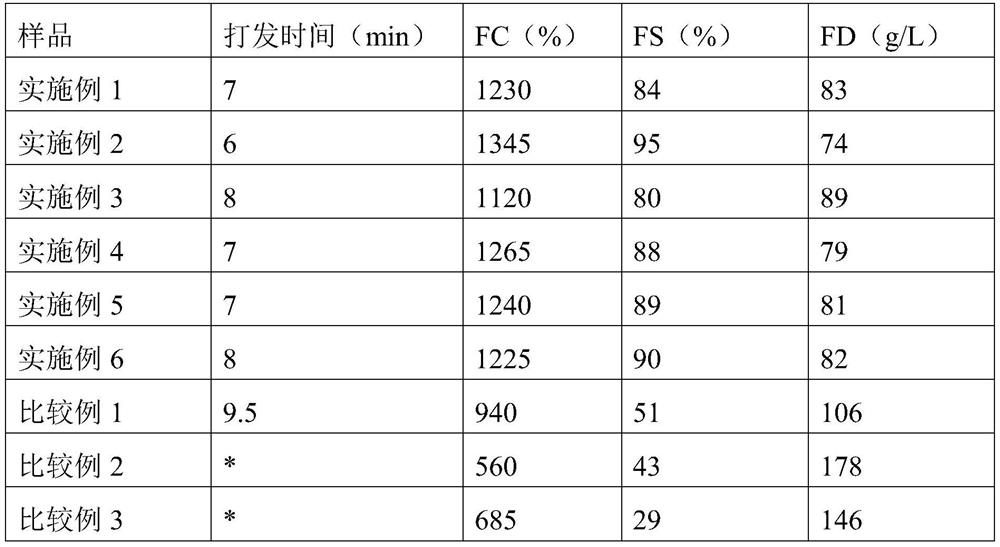

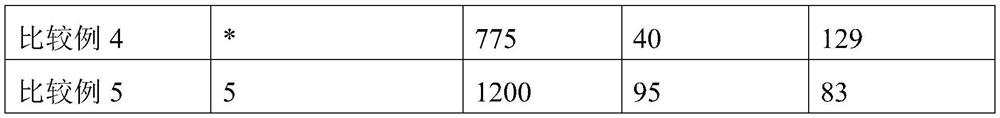

Examples

preparation example Construction

[0052] Therefore, the present invention provides a method for preparing a soybean protein composition having high foaming properties and foaming stability. The method includes the steps of fermentation, hydration and enzymolysis.

[0053] Fermentation involves adding fermentation strains to a soybean meal suspension containing soybean meal and carbohydrates for fermentation. Carbohydrates can be various sugars known in the art, including monosaccharides or oligosaccharides. Examples of monosaccharides include five-carbon sugars such as ribose and deoxyribose, and six-carbon sugars such as glucose, fructose, and galactose; oligosaccharides include disaccharides, trisaccharides, and tetrasaccharides, etc., and maltose, sucrose, and lactose, etc. The soybean meal can be low-temperature soybean meal obtained by low-temperature deoiling and desolventization of soybeans. In some embodiments, the soybean meal has a protein content of 45-55 wt%, a fat content of 0-3 wt%, a dietary f...

Embodiment 1

[0085] Weigh 100g of soybean meal powder obtained by crushing and sieving (40 mesh), add 900g of water, stir evenly, add 15g of glucose therein, stir evenly, heat at 80°C for 15min for pasteurization. Then insert the mixed strains into the soybean meal suspension, the insertion ratio is 0.5‰ of the weight of the soybean meal powder, and the mixed strains include Lactobacillus plantarum, Lactobacillus acidophilus, and Lactobacillus lactis in a ratio of 10:10:10:2:2. Mycobacterium, Bacillus coagulans and Lactobacillus rhamnosus were fermented at a constant temperature of 40°C. Changes in pH during the detection process. When the pH dropped to 4.7, pasteurization was performed under the same conditions again to terminate the fermentation. Then the soybean meal fermentation liquid was centrifuged under the condition of 3000g for 10min, and the precipitate was taken, and 2 times of water (weight ratio) was added to the precipitate, and the suspension was adjusted to pH 7.3 with 2M...

Embodiment 2

[0087] Weigh 100g of soybean meal powder obtained by crushing and sieving (40 mesh), add 900g of water, stir evenly, add 15g of glucose therein, stir evenly, heat at 80°C for 15min for pasteurization. Then insert the mixed strains into the soybean meal suspension, the insertion ratio is 0.5‰ of the weight of the soybean meal powder, and the mixed strains include Lactobacillus plantarum, Lactobacillus acidophilus, and Lactobacillus lactis in a ratio of 10:10:10:2:2. Mycobacterium, Bacillus coagulans and Lactobacillus rhamnosus were fermented at a constant temperature of 40°C. Changes in pH during the detection process. When the pH drops to 4.0, pasteurize again under the same conditions to terminate the fermentation. Then the soybean meal fermentation liquid was centrifuged under the condition of 3000g for 10min, and the precipitate was taken, and then 3 times (weight ratio) of water was added to the precipitate, and the suspension was adjusted to pH 7.7 with 2M NaOH, and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com