Metal-based ceramic composite grinding roller and preparation method thereof

A ceramic composite and metal-based technology, applied in grain processing, etc., can solve problems such as fracture, poor density, and limited wear resistance of low-alloy steel, and achieve simple preparation and operation process and strong structural adjustability , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

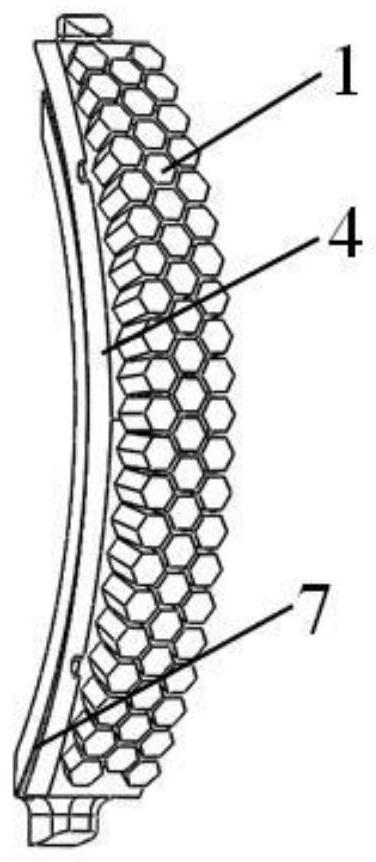

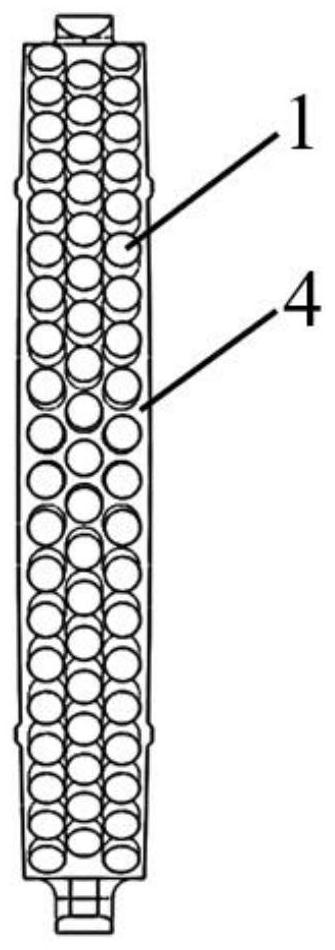

[0052] (1) According to the CPM10V, CPM15V, Al in the mixture 2 o 3 , ZrO 2 The mass percentages of VC, WC are 18%, 20%, 5%, 12%, 25%, and 20% in sequence. The above materials are mixed, and then hot isostatically pressed at 1100°C and 160MPa for 2 hours to make a hexagonal column Shaped carbide rods.

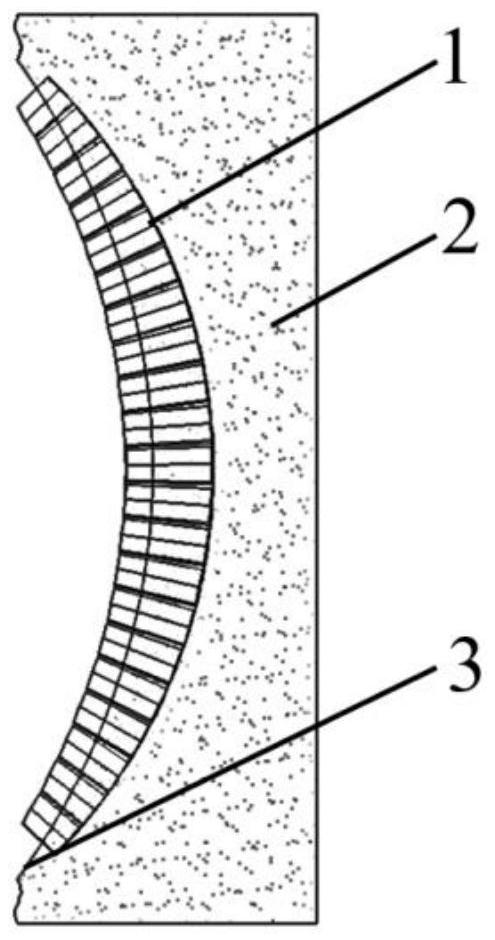

[0053] Distribute a plurality of prepared hexagonal tungsten carbide rods evenly in the molding sand, the contour line of the molding sand is an arc line, the larger end of the cemented carbide rod is fixed in the molding sand, and the smaller end is exposed to the molding sand for 20~ 30mm; multiple cemented carbide rods are arranged in at least one row and fixed in the molding sand, and the minimum distance between any two adjacent cemented carbide rods with larger end faces is 4-6mm. Preheat the cemented carbide rod fixed in the molding sand at 500°C, and keep it at this temperature for 3 hours; then pour the molten metal of the base material (one of carbon steel, high ma...

Embodiment 2

[0058] Step (1) according to CPM10V, CPM15V, Al 2 o 3 , ZrO 2 The mass percentages of , VC, and WC are 20%, 20%, 10%, 12%, 18%, and 20% in sequence. Hot isostatic pressing at 1150°C and 180MPa for 3 hours to make cylindrical carbide rods and molding sand The outline is an arc, the preheating temperature is 550°C, and the holding time is 2h;

[0059] Step (2) Hot isostatic pressing at 1100°C and 170MPa for 2 hours, and composited to obtain a wear-resistant composite strip;

[0060] In step (3), preheat and keep warm at 500° C. for 3 hours, and then pour the parent metal liquid into the cavity of the mold to obtain a circular composite grinding roller with a tire structure. The parent metal liquid is one of QT500-7 and QT600-3.

[0061] Others are with embodiment 1.

Embodiment 3

[0063] Step (1) according to CPM10V, CPM15V, Al 2 o 3 , ZrO 2 The mass percentages of , VC, and WC are 15%, 18%, 12%, 10%, 20%, and 25% in sequence. Hot isostatic pressing at 1180°C and 160MPa for 2 hours makes a hexagonal columnar cemented carbide rod. The contour line of the molding sand is a straight line, the preheating temperature is 600°C, and the holding time is 3h;

[0064] Step (2) Hot isostatic pressing at 1180°C and 160MPa for 3 hours, and composited to obtain a wear-resistant composite strip;

[0065] In step (3), preheat and keep warm at 550° C. for 2 hours, and then pour the parent metal liquid into the cavity of the mold to obtain a circular and conical composite grinding roller. The parent metal liquid is one of QT500-7 and QT600-3.

[0066] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com