Essential oil patch for relieving stuffy nose and preparation method thereof

An essential oil and nose-clearing technology, which is applied in the direction of medical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problem of poor slow-release effect of essential oils, short-term effect of essential oil patches, redness, swelling, allergies, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

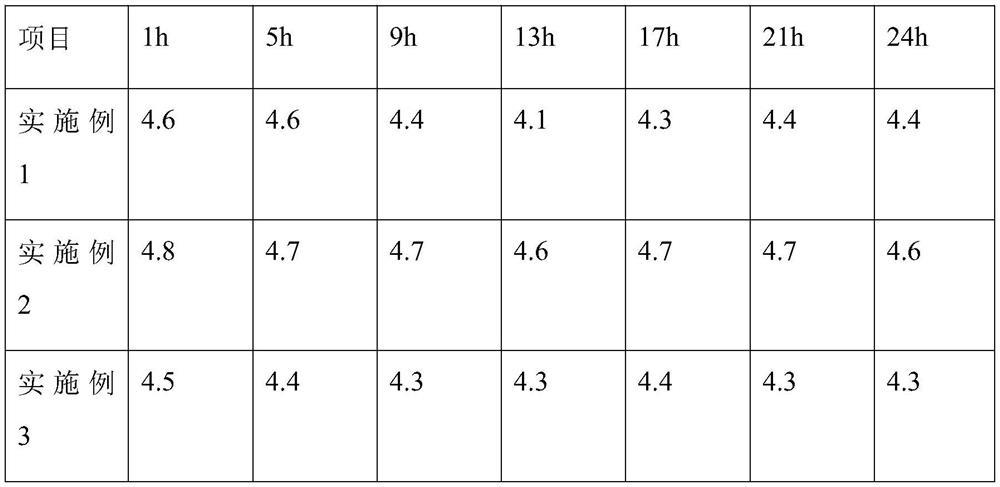

Embodiment 1

[0033] A preparation method for nose-relieving essential oil patch, comprising the following steps:

[0034] (1) Preparation of silica microspheres:

[0035] S1: Take glucose and deionized water, mix them evenly and add sodium polystyrene sulfonate, the amount of sodium polystyrene sulfonate added is 0.5wt% of the amount of glucose added; Heat the reaction for 9 hours. After the reaction, the product was collected by filtration, washed with deionized water and absolute ethanol in sequence, and dried in vacuum; the dried product was transferred to 850°C and activated for 1.5 hours in an air atmosphere to obtain porous carbon microspheres.

[0036] Take porous carbon microspheres and cetyltrimethylammonium chloride solution and mix them, stir and react at 20°C for 14h at a stirring speed of 180rpm to obtain modified carbon microspheres; the cetyltrimethylchloride The concentration of the ammonium solution is 2mmol / L; the consumption of the porous carbon microspheres and cetyltr...

Embodiment 2

[0045] A preparation method for nose-relieving essential oil patch, comprising the following steps:

[0046] (1) Preparation of silica microspheres:

[0047] S1: Take glucose and deionized water, mix them evenly and add sodium polystyrene sulfonate, the amount of sodium polystyrene sulfonate added is 0.5wt% of the amount of glucose added; continue to stir until dissolved. Heat the reaction for 8.5 hours. After the reaction, the product was collected by filtration, washed with deionized water and absolute ethanol in sequence, and dried in vacuum; the dried product was transferred to 880°C and activated for 1.2 hours in an air atmosphere to obtain porous carbon microspheres.

[0048] Take porous carbon microspheres and cetyltrimethylammonium chloride solution and mix them, stir and react at 25°C for 13h at a stirring speed of 180rpm to obtain modified carbon microspheres; the cetyltrimethylchloride The concentration of the ammonium solution is 2mmol / L; the consumption of the po...

Embodiment 3

[0057] A preparation method for nose-relieving essential oil patch, comprising the following steps:

[0058] (1) Preparation of silica microspheres:

[0059] S1: Take glucose and deionized water, mix them evenly and add sodium polystyrene sulfonate, the amount of sodium polystyrene sulfonate added is 0.5wt% of the amount of glucose added; Heat the reaction for 8 hours. After the reaction, the product was collected by filtration, washed with deionized water and absolute ethanol in turn, and dried in vacuum; the dried product was transferred to 900°C and activated for 1 hour in an air atmosphere to obtain porous carbon microspheres.

[0060] Take porous carbon microspheres and cetyltrimethylammonium chloride solution and mix them, stir and react at 25°C for 12h at a stirring speed of 180rpm to obtain modified carbon microspheres; the cetyltrimethylchloride The concentration of the ammonium solution is 2mmol / L; the consumption of the porous carbon microspheres and cetyltrimethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com