A thermosensitive liquid crystal nano hydrogel and its preparation method and application

A nano-hydrogel and temperature-sensitive technology, which can be used in applications, pharmaceutical formulations, liquid delivery, etc., can solve the problems of weak slow-release effect, no temperature sensitivity, and poor biocompatibility of hydrogel preparations. Achieve the effects of increasing drug loading and encapsulation efficiency, improving bioavailability, and easy raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

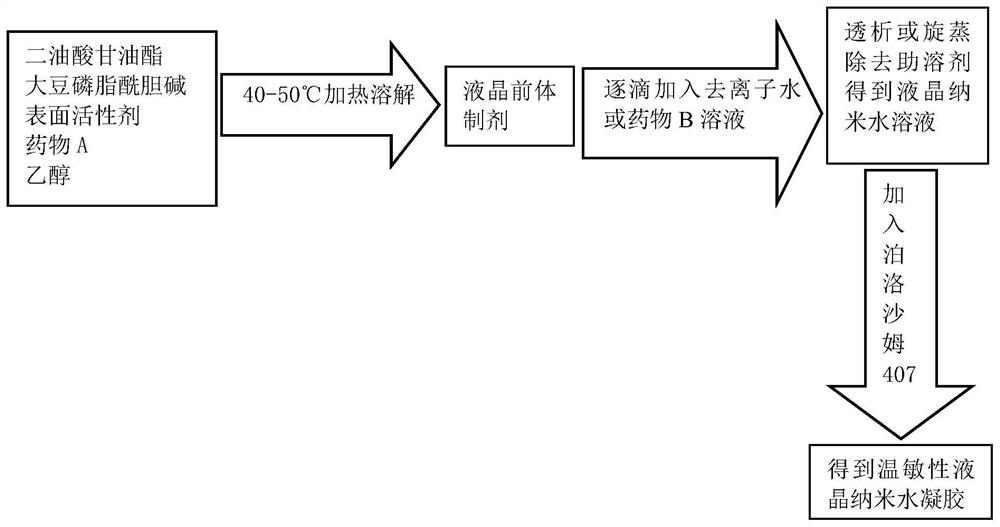

[0039]A kind of preparation method of thermosensitive liquid crystal nano hydrogel, see flow chart figure 1 .

[0040] (1) Dissolve the liquid crystal material glyceryl dioleate (GDO) and soybean phosphatidylcholine (SPC) in a co-solvent at 25°C-50°C. The mass ratio of the alkali (SPC) is 1:1, and a surfactant is added to obtain a liquid crystal precursor;

[0041] (2) Under ultrasonic conditions, add the liquid crystal precursor described in step (1) dropwise into deionized water or a water-soluble drug solution to obtain a liquid crystal nanohydrogel; after removing the cosolvent by rotary evaporation, add Temperature-sensitive materials, that is, temperature-sensitive liquid crystal nano hydrogels are obtained.

[0042] Take the prepared SPC / GDO liquid crystal precursor preparation and prepare 50mg / mL, 75mg / mL and 100mg / mL nano-solutions respectively according to the prescription in Table 1 for use.

[0043] Table 1 Preparation of nano-solutions with different concentrat...

Embodiment 2

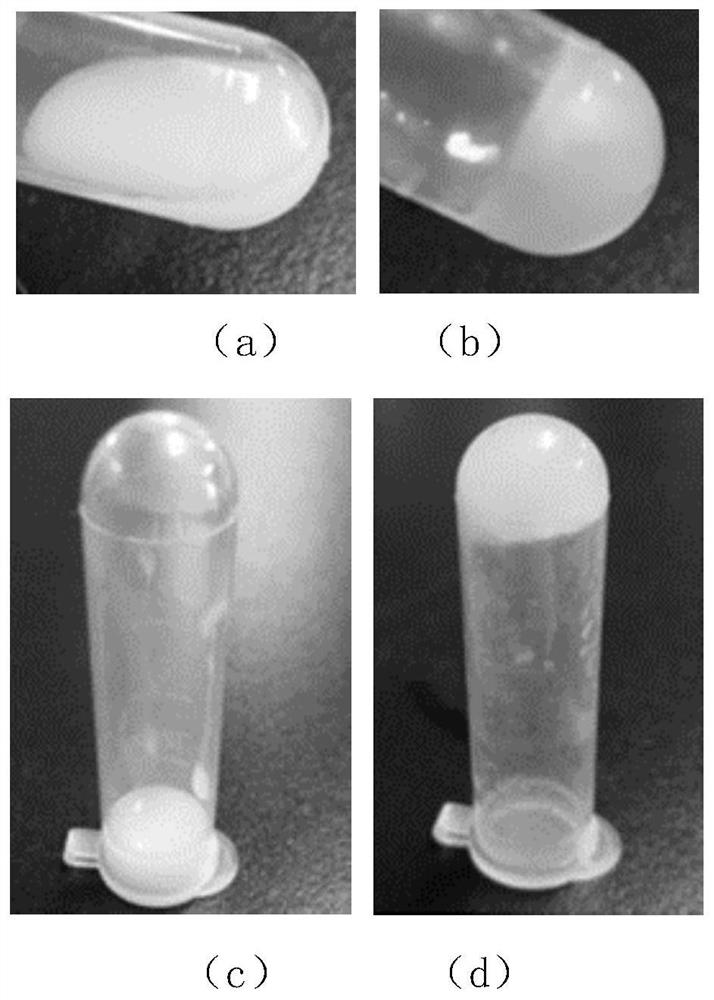

[0057] Weigh 0.5g of glyceryl dioleate and 0.5g of soybean phosphatidylcholine, and add them to 0.2g of absolute ethanol to dissolve at 40°C to obtain a liquid crystal precursor; due to the above ratio of soybean phosphatidylcholine Alkali and diolein liquid crystal precursors can quickly form liquid crystal gels with high strength after meeting water, so in theory, the above-mentioned soybean phosphatidylcholine and diolein liquid crystal precursors are slowly and gradually synthesized under ultrasonic conditions. Adding it dropwise into the water phase can disperse it to obtain a uniform liquid crystal nanogel solution.

[0058] During the operation, it was found that when using a single-channel pipette to absorb the liquid crystal precursor and drop it into the water, due to the high viscosity of the liquid crystal precursor and the small diameter of the pipette gun tip, it is easy to cause blockage, and it is almost impossible to remove the liquid crystal precursor. Drop i...

Embodiment 3

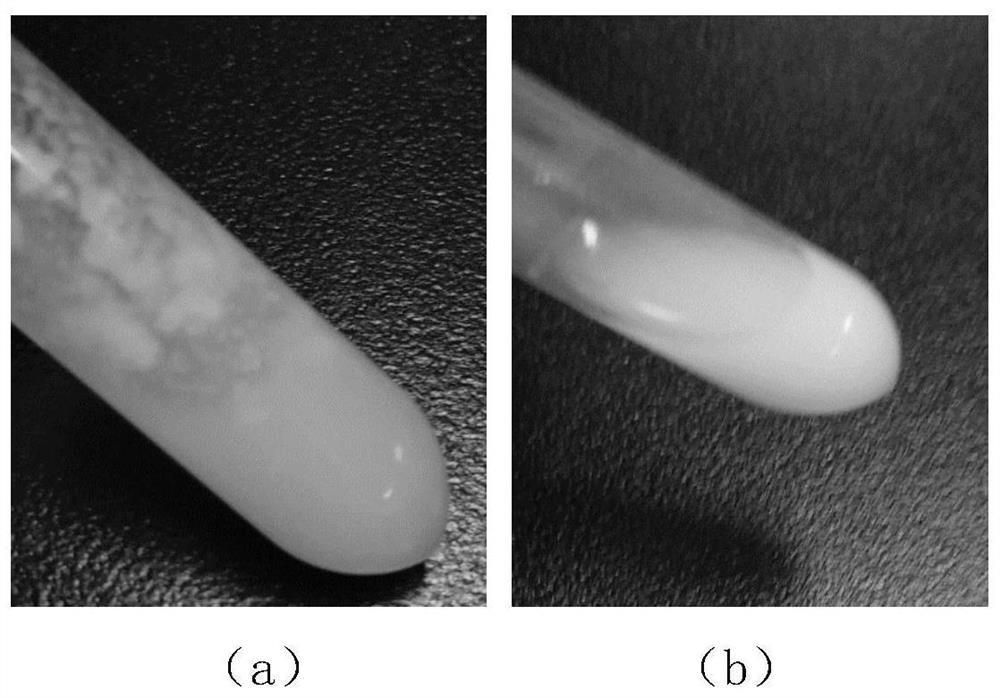

[0062] For the samples that can be gelled, when the temperature of the sample is lowered, the sample can become fluid again, and can be gelled when the temperature is raised, indicating that the gelation process of the hybrid nanogel system has good reversibility.

[0063] In order to show the phase transition temperature of the mixed nanogel system more intuitively, it is planned to use a rheometer to measure the elastic modulus (G') and viscous modulus (G") of the mixed nanogel system, when tan(δ)= 1, that is, when the loss tangent = G" / G' = 1, the corresponding temperature at this time is regarded as the phase transition temperature of the mixed nanogel system.

[0064] Take 200 uL of the sample of group 3 in Table 2, and put it into the test pan of the rheometer, set the frequency to 1 Hz, the strain to 0.3%, and the temperature rise range: 20°C to 40°C. The heating rate is 1°C / min. To prevent the evaporation of water in the mixed nanogel system from affecting the results...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com