Vanadium-nitrogen co-doped titanium-containing blast furnace slag photocatalytic material and preparation method thereof

A technology of photocatalytic materials and blast furnace slag, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effect of improving photocatalytic efficiency and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

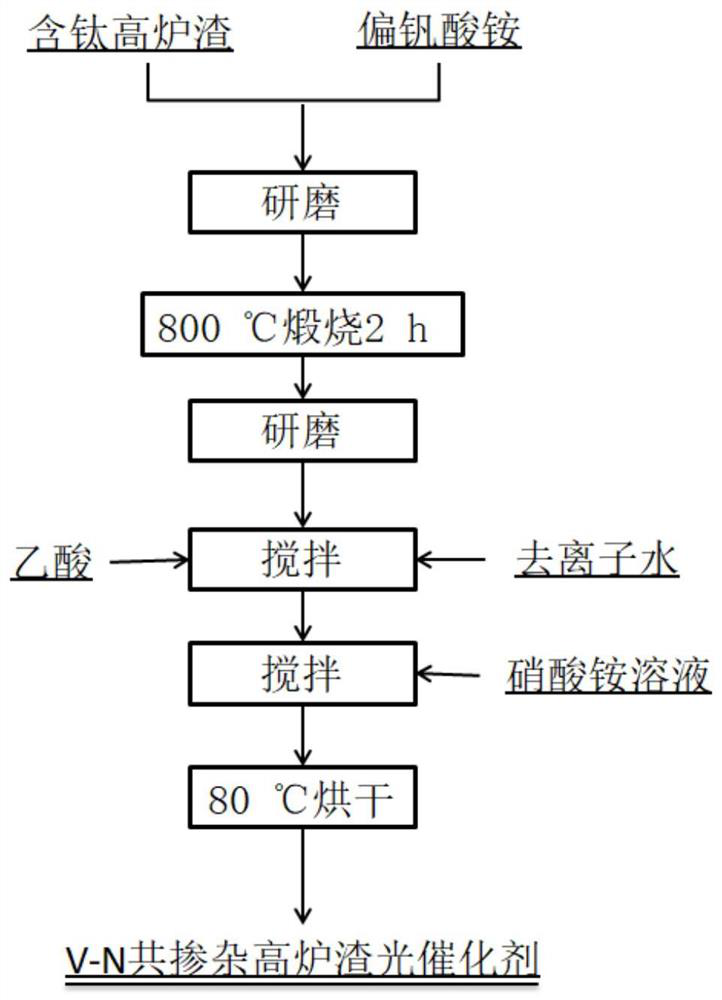

[0018] A method for preparing a vanadium nitrogen co-doped titanium-containing blast furnace slag photocatalytic material, comprising the following steps:

[0019] 1. First use a ball mill to grind the blast furnace slag to 100-200 mesh, and then use an agate mortar to hand-grind it to tens of microns.

[0020] 2. Put 10 g of pretreated high-titanium blast furnace slag into an agate mortar, and manually mix it with 1.42 g (doping amount: 45%) of ammonium metavanadate for about 120 minutes. Then, a vanadium-doped photocatalyst was prepared by a multi-component solid-phase sintering method, and the mixture was calcined in a muffle furnace at 800° C. for about two hours.

[0021] 3. Wait for it to cool down to room temperature naturally, and then use an agate mortar to hand grind it to tens of microns to obtain a photocatalyst of vanadium-doped high-titanium blast furnace slag.

[0022] 4. The liquid phase method is adopted, and the high-titanium type blast furnace slag doped wi...

Embodiment 2

[0025] A method for preparing a vanadium nitrogen co-doped titanium-containing blast furnace slag photocatalytic material, comprising the following steps:

[0026] 1. First use a ball mill to grind the blast furnace slag to 100-200 mesh, and then use an agate mortar to hand-grind it to tens of microns.

[0027] 2. Put 10 g of pretreated high-titanium blast furnace slag into an agate mortar, and manually mix it with 1.42 g (doping amount: 45%) of ammonium metavanadate for about 120 minutes. Then, a vanadium-doped photocatalyst was prepared by a multi-component solid-phase sintering method, and the mixture was calcined in a muffle furnace at 800° C. for about two hours.

[0028] 3. Wait for it to cool down to room temperature naturally, and then use an agate mortar to hand grind it to tens of microns to obtain a photocatalyst of vanadium-doped high-titanium blast furnace slag.

[0029] 4. The liquid phase method is adopted, and the high-titanium type blast furnace slag doped wi...

Embodiment 3

[0032] A method for preparing a vanadium nitrogen co-doped titanium-containing blast furnace slag photocatalytic material, comprising the following steps:

[0033] 1. First use a ball mill to grind the blast furnace slag to 100-200 mesh, and then use an agate mortar to hand-grind it to tens of microns.

[0034] 2. Put 10 g of pretreated high-titanium blast furnace slag into an agate mortar, and manually mix it with 1.42 g (doping amount: 45%) of ammonium metavanadate for about 120 minutes. Then, a vanadium-doped photocatalyst was prepared by a multi-component solid-phase sintering method, and the mixture was calcined in a muffle furnace at 800° C. for about two hours.

[0035] 3. Wait for it to cool down to room temperature naturally, and then use an agate mortar to hand grind it to tens of microns to obtain a photocatalyst of vanadium-doped high-titanium blast furnace slag.

[0036]4. The liquid phase method is adopted, and the high-titanium type blast furnace slag doped wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com