Device and method for preparing metal vanadium from vanadium alloy

A vanadium alloy and metal technology, applied in the field of devices for preparing metal vanadium, can solve the problems of high cost, poor plasticity, low content of vanadium chloride, etc., and achieve the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

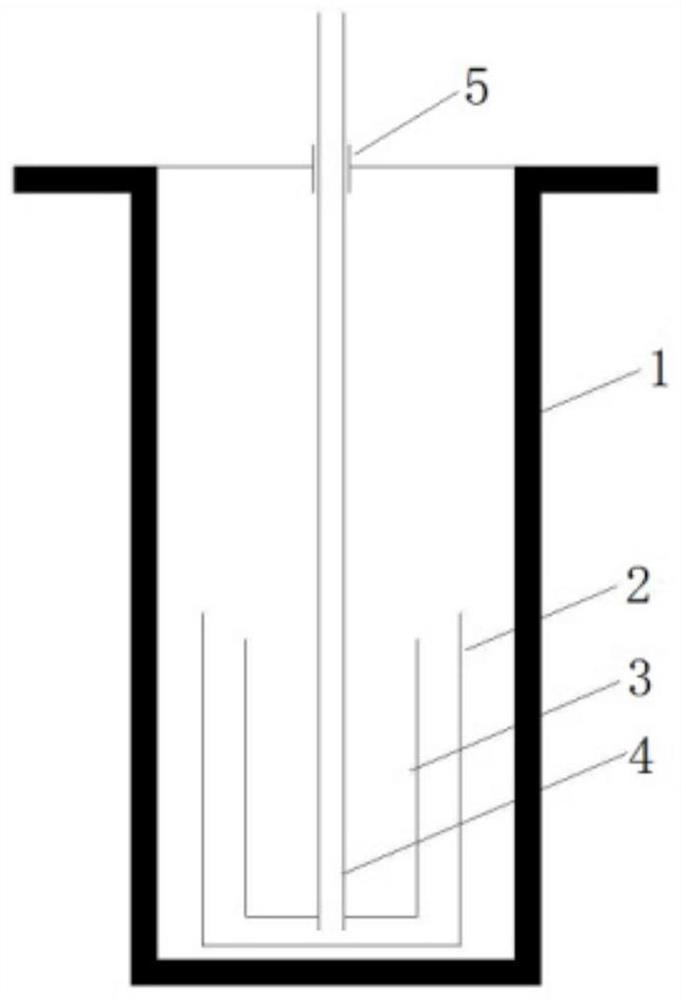

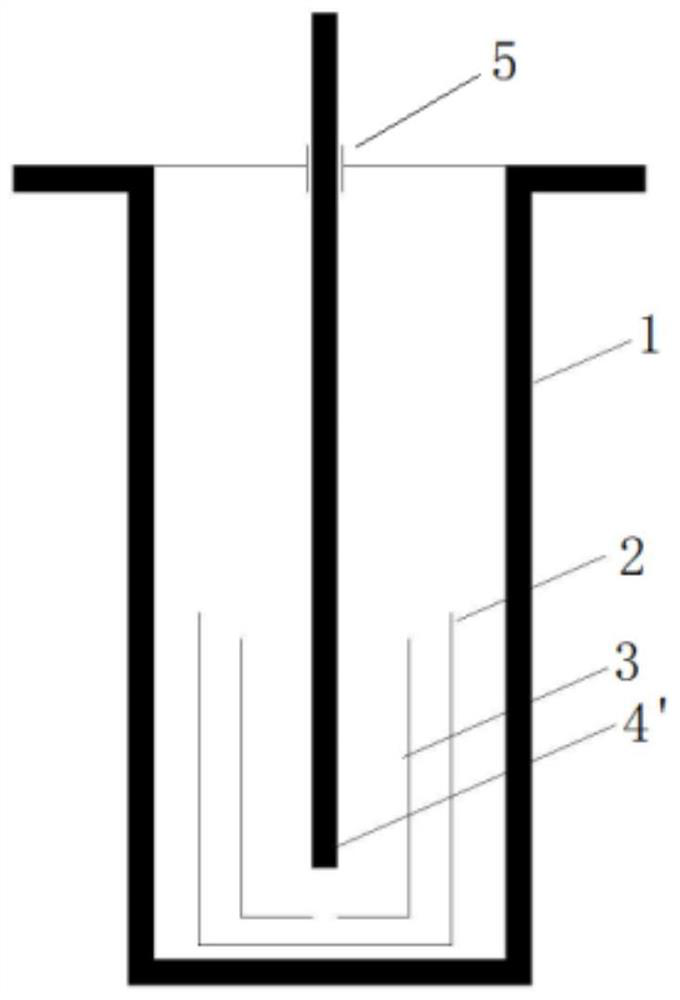

[0056] The present embodiment provides a device for preparing metal vanadium from vanadium alloy, and the device is used for preparing vanadium chloride by reacting vanadium alloy with chlorine gas and preparing vanadium metal by electrolysis of vanadium chloride, and the device includes:

[0057] The heating furnace includes a furnace body and a furnace cover, and the furnace cover is provided with a first through hole communicating with the furnace body;

[0058] The graphite crucible and the corundum crucible, wherein the inner wall of the graphite crucible is provided with a support ring, the corundum crucible is arranged on the support ring, and the distance between the corundum crucible and the side wall of the graphite crucible is controlled at 3cm, the bottom distance is 2cm, and the bottom of the corundum crucible is provided with a second The through hole, specifically, the diameter of the graphite crucible is 18cm, and the height is 22cm, and the diameter of the coru...

Embodiment 2

[0065] The present embodiment provides a method for preparing metallic vanadium from vanadium alloy, which is prepared with the device in embodiment 1, including the following steps:

[0066] Step 1. Put the graphite crucible into the heating furnace body, add 200g chloride to the graphite crucible, place the corundum crucible in the graphite crucible, add 200g and 800g of vanadium alloy particles between the graphite crucible and the corundum Heating and melting at 650°C to obtain a first mixture, wherein the particle size of the vanadium alloy is 0.8-1.2 cm, and the chloride is a mixture of potassium chloride and lithium chloride with a mass ratio of 1:1;

[0067] Step 2, insert the corundum tube into the second through hole of the corundum crucible, and pass chlorine gas into the first mixture through the corundum tube, and control the pressure of the chlorine gas to be 0.20MPa, the flow rate is 5NL / min, and the time is 2.5h. to obtain a second mixture;

[0068] Step 3. Pu...

Embodiment 3

[0071] The present embodiment provides a method for preparing metallic vanadium from vanadium alloy, which is prepared with the device in embodiment 1, including the following steps:

[0072] Step 1. Put the graphite crucible into the heating furnace body, add 200g chloride to the graphite crucible, place the corundum crucible in the graphite crucible, add 200g and 800g of vanadium alloy particles between the graphite crucible and the corundum Heating and melting at 630° C. to obtain a first mixture, wherein the particle size of the vanadium alloy is 0.8-1.2 cm, and the chloride is a mixture of potassium chloride and sodium chloride with a mass ratio of 0.8:1;

[0073] Step 2, insert the corundum tube into the second through hole of the corundum crucible, and pass chlorine gas into the first mixture through the corundum tube, and control the pressure of the chlorine gas to be fed into 0.15MPa, the flow rate is 5.5NL / min, and the time is 2.5h, preparing a second mixture;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com