Cellulose acetate fiber for heavy metal substance adsorption type cigarette and preparation method of cellulose acetate fiber

A technology of cellulose acetate and cellulose diacetate, which is applied in the fields of tobacco, application, smoke oil filter elements, etc., to achieve the effects of simple preparation process, high adsorption effect, and high adsorption stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

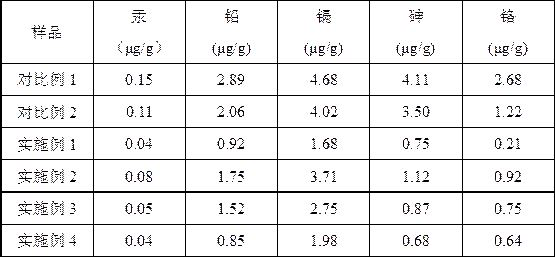

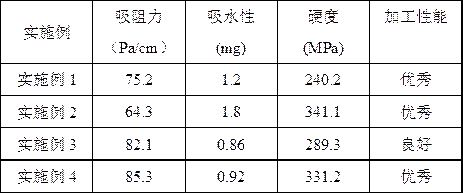

Examples

Embodiment 1

[0031] A heavy metal substance adsorption type cigarette acetate fiber, the acetate fiber comprises cellulose diacetate and vegetable protein bonded and / or associated with the cellulose diacetate; wherein, the vegetable protein can interact with heavy metal ions form a coordinate bond. It is prepared by the following steps:

[0032] (1) Diacetate cellulose (molecular weight 45kD, diameter 200μm, porosity 200 mesh) was melted and drawn to form cellulose diacetate tow, then soaked and cleaned in water, ethanol, isopropanol, and secondary water, respectively, and placed in Dry in an oven at 50°C for later use;

[0033] (2) Add soybean protein isolate to 1% NaOH aqueous solution and stir for 2 hours to prepare a soybean protein isolate alkali solution with a concentration of 5wt%;

[0034](3) adding zein to 75% ethanol, stirring until completely dissolved, and configuring a zein solution with a concentration of 2wt%;

[0035] (4) adding the cellulose diacetate tow obtained in s...

Embodiment 2

[0039] A heavy metal substance adsorption type cellulose acetate for tobacco is prepared by the following steps:

[0040] (1) Diacetate cellulose (molecular weight 40kD, diameter 50μm, porosity 300 mesh) was melted and drawn to form cellulose diacetate tow, then soaked and cleaned in water, ethanol, isopropanol, and secondary water, respectively, and placed in a Dry in an oven at 50°C for later use;

[0041] (2) Add soybean protein isolate to a 1% NaOH aqueous solution and stir for 2 hours to prepare a soybean protein isolate alkali solution with a concentration of 10wt%;

[0042] (3) adding zein to 75% ethanol, stirring until completely dissolved, and configuring a zein solution with a concentration of 10wt%;

[0043] (4) adding the cellulose diacetate tow obtained in step (1) into the KOH-hydrogen peroxide solution for surface plasma treatment;

[0044] (5) soaking the diacetate fiber tow obtained in step (4) in the soybean protein solution of step (2) for 10 minutes, and ...

Embodiment 3

[0048] A heavy metal substance adsorption type cellulose acetate for tobacco is prepared by the following steps:

[0049] (1) Diacetate cellulose (molecular weight 30kD, diameter 100μm, porosity 100 mesh) was melted and drawn to form cellulose diacetate tow, and then soaked and cleaned in water, ethanol, isopropanol and secondary water respectively, and placed in Dry in an oven at 50°C for later use;

[0050] (2) The soybean tissue protein was added to a 1% NaOH aqueous solution and stirred for 2 hours to prepare a soybean protein isolate alkali solution with a concentration of 0.1 wt%;

[0051] (3) adding zein to 75% ethanol, stirring until completely dissolved, and configuring a zein solution with a concentration of 10wt%;

[0052] (4) adding the cellulose diacetate tow obtained in step (1) into the KOH-hydrogen peroxide solution for surface plasma treatment;

[0053] (5) soaking the diacetate fiber tow obtained in step (4) in the soybean protein solution of step (2) for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com