Method for extracting, separating, purifying and detecting alangium total alkaloids

A technology for separation and purification of total alkaloids, applied in the field of pharmaceutical inventions, can solve problems such as low recovery rate, drug poisoning, and poor repeatability, and achieve a stable extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

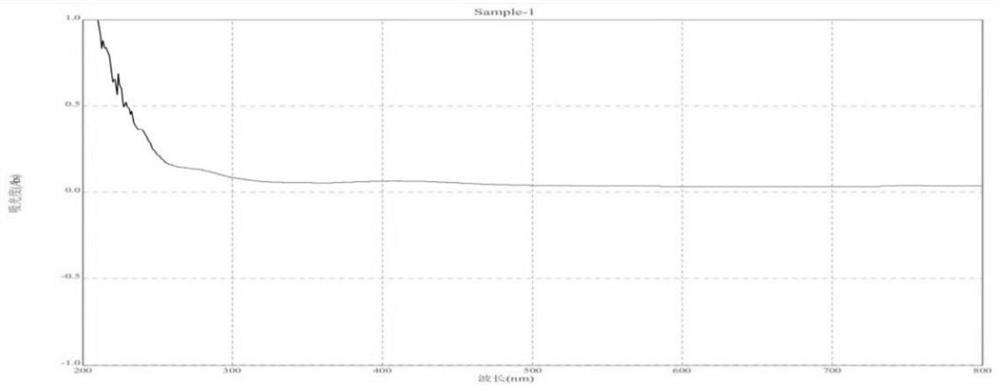

[0060] Example 1 Extraction, separation and purification

[0061] (1) Preparation of crude extract: Accurately weigh 200 g of the medicinal powder of Maple anise, put it in a round-bottomed flask, add 10 times the amount of 80% ethanol, reflux for 2 times, 2h each time, filter, combine the crude extract, and set aside for later use ;

[0062] (2) Preparation of sample solution: take the crude extract to recover ethanol with a rotary evaporator, concentrate to 500mL, add an appropriate amount of 80% ethanol to dilute to obtain a solution with a concentration of 3.02mg / mL, and then adjust it with sodium hydroxide and hydrochloric acid The pH of the solution is 6, that is, the sample solution;

[0063] (3) Separation and purification: Take D101 macroporous adsorption resin, pack the column by wet method with a diameter-to-height ratio of 1:3, take 15 mL of the sample solution, load the sample at a flow rate of 1 mL / min, collect the effluent, and let it stand for 1 h Then; elute...

Embodiment 2

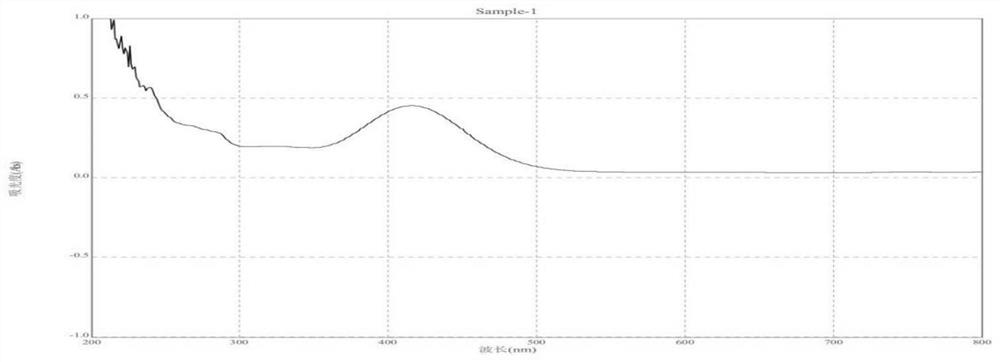

[0064] Example 2 Extraction, separation and purification

[0065] (1) Preparation of crude extract: Accurately weigh 150 g of the medicinal powder of Maple anise, put it in a round-bottomed flask, add 8 times the amount of 60% ethanol, extract by reflux once, 1h each time, filter, combine the crude extracts, and set aside for later use ;

[0066] (2) Preparation of sample solution: take the crude extract to recover ethanol with a rotary evaporator, concentrate to 400mL, add an appropriate amount of 60% ethanol to dilute to obtain a solution with a concentration of 2.00mg / mL, and then adjust it with sodium hydroxide and hydrochloric acid The pH of the solution is 2, that is, the sample solution;

[0067] (3) Separation and purification: Take D101 macroporous adsorption resin, pack the column by wet method with a diameter-to-height ratio of 1:1, take 5 mL of the sample solution, load the sample at a flow rate of 1 mL / min, collect the effluent, and let it stand for 1 h Then; el...

Embodiment 3

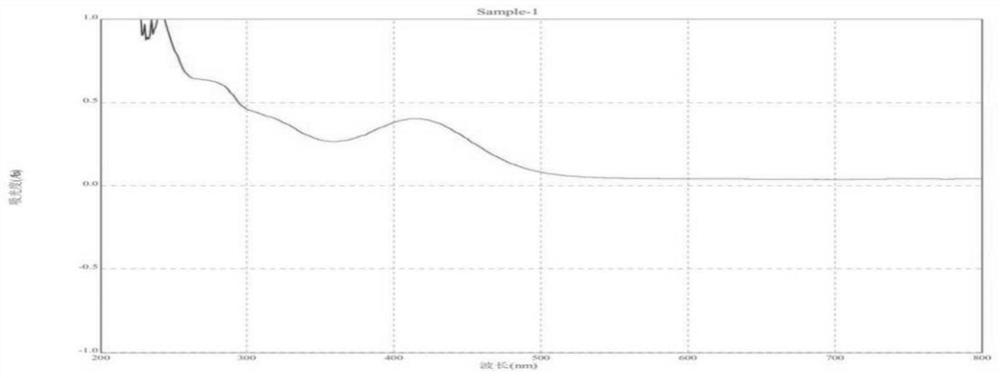

[0068] Example 3 Extraction, separation and purification

[0069] (1) Preparation of crude extract: Accurately weigh 250g of the medicinal powder of Maple anise, put it in a round-bottomed flask, add 12 times the amount of 90% ethanol, reflux for 3 times, 3h each time, filter, combine the crude extract, and set aside for later use ;

[0070] (2) Preparation of sample solution: take the crude extract to recover ethanol with a rotary evaporator, concentrate it to 450mL, add an appropriate amount of 90% ethanol to dilute to obtain a solution with a concentration of 6.00mg / mL, and then adjust it with sodium hydroxide and hydrochloric acid The pH of the solution is 8, that is, the sample solution;

[0071] (3) Separation and purification: Take D101 macroporous adsorption resin, pack the column by wet method with a diameter-to-height ratio of 1:4, take 45 mL of the sample solution, load the sample at a flow rate of 1 mL / min, collect the effluent, and let it stand for 1 h Then; elu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com