Tendon repair material, preparation method and application in preparation of tendon repair product

A technology for repairing materials and tendons, used in the preparation of tendon repair products, in the field of tendon repair materials, can solve problems such as unfavorable industrial production, avoid the destruction of beneficial components, avoid the risk of inflammation in body tissues, and reduce chemical residues. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

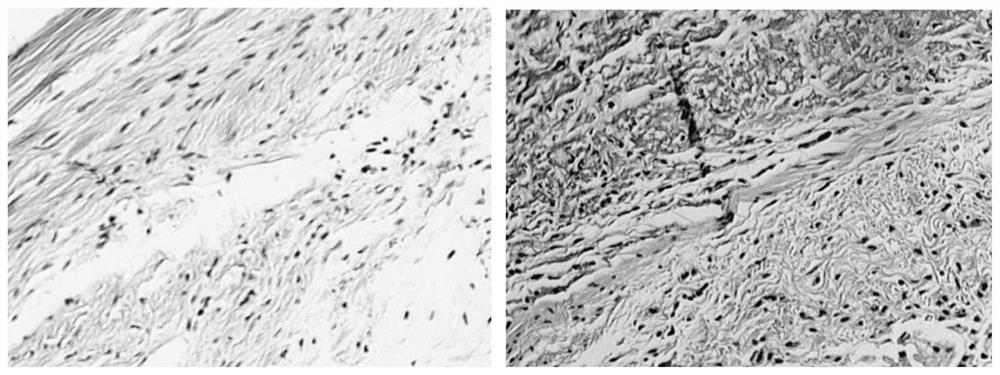

[0069] 1. Preparation of acellular matrix gel from bovine Achilles tendon

[0070] (1) The bovine Achilles tendon was ultrasonically cleaned with oxidative potential water to remove surface viruses, and then placed at -20°C for 3 times of repeated freezing and thawing, and the surface oil of the tissue was scraped off. Immerse bovine Achilles tendon in 0.5mol / LEDTA solution at room temperature and 25℃, shake for 1.5h, and then place in 5MNaCl, 0.05M NaOH, 0.5M Na 2 CO 3 In the mixed hypertonic solution, shake for 40 min, repeat the process 8 times, and finally use pure water to shake for 1 h, repeat 5 times.

[0071](2) Removal of immunogenicity: The residual nucleic acid and telopeptide were removed with PBS solution containing 0.1% nuclease and pepsin respectively, and the decellularized matrix of bovine Achilles tendon tissue was obtained after washing with PBS buffer for several times, which was frozen Dry to obtain a porous decellularized scaffold material.

[0072] (3...

Embodiment 2

[0078] 1. Preparation of acellular matrix gels of bovine ligaments

[0079] (1) The bovine ligament tissue was ultrasonically cleaned with oxidative potential water to remove the virus on the surface of the ligament tissue, and then placed at -20°C for 4 times of repeated freezing and thawing, and the surface oil was scraped off. Immerse bovine ligament tissue in 0.5mol / LEDTA solution at room temperature and 25℃, shake for 2.0h, and then place in 1.0M NaCl, 0.5M NaOH, 0.2M Na 2 CO 3 The mixed hypertonic solution was shaken for 40 min, and the process was repeated 5 times; finally, purified water was used to shake for 1 h and repeated 10 times.

[0080] (2) Removal of immunogenicity: The residual nucleic acid and telopeptide were removed with PBS solution containing 0.05% nuclease and pepsin respectively, and the decellularized matrix of bovine ligament tissue was obtained after washing with PBS buffer for several times, and then freeze-dried Obtain the corresponding decellul...

Embodiment 3

[0087] 1. Preparation of bovine Achilles tendon extracellular matrix and gel

[0088] (1) The bovine Achilles tendon was ultrasonically cleaned with oxidative potential water to remove the virus on the surface of the animal, placed at -20°C for 4 times of repeated freezing and thawing, and the surface oil of the tissue was scraped off. Immerse animal tissue in 0.5mol / LEDTA solution at room temperature and 25℃, shake for 1 h, and then place in 3M NaCl, 0.1M NaOH, 1M Na 2 CO 3 The mixed hypertonic solution was shaken for 40 min, and the process was repeated 10 times. Finally, pure water was used to shake for 1 h and repeated 6 times.

[0089] (2) Removal of immunogenicity: The residual nucleic acid and telopeptide were removed with PBS solution containing 0.08% nuclease and pepsin respectively, and the acellular matrix of bovine Achilles tendon tissue was obtained after washing with PBS buffer for several times. Freeze-drying to obtain porous scaffold material.

[0090] (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com