High-performance AlON transparent ceramic and low-temperature rapid preparation method thereof

A transparent ceramic, high-performance technology, applied in the field of high-performance AlON transparent ceramics and its low-temperature rapid preparation, which can solve the problem of the decrease in the transmittance and mechanical properties of AlON transparent ceramics, the decrease in the transmittance of AlON transparent ceramics, and the difficulty of sample densification, etc. The problem is to shorten the sintering time, improve the comprehensive mechanical properties, and inhibit the grain growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

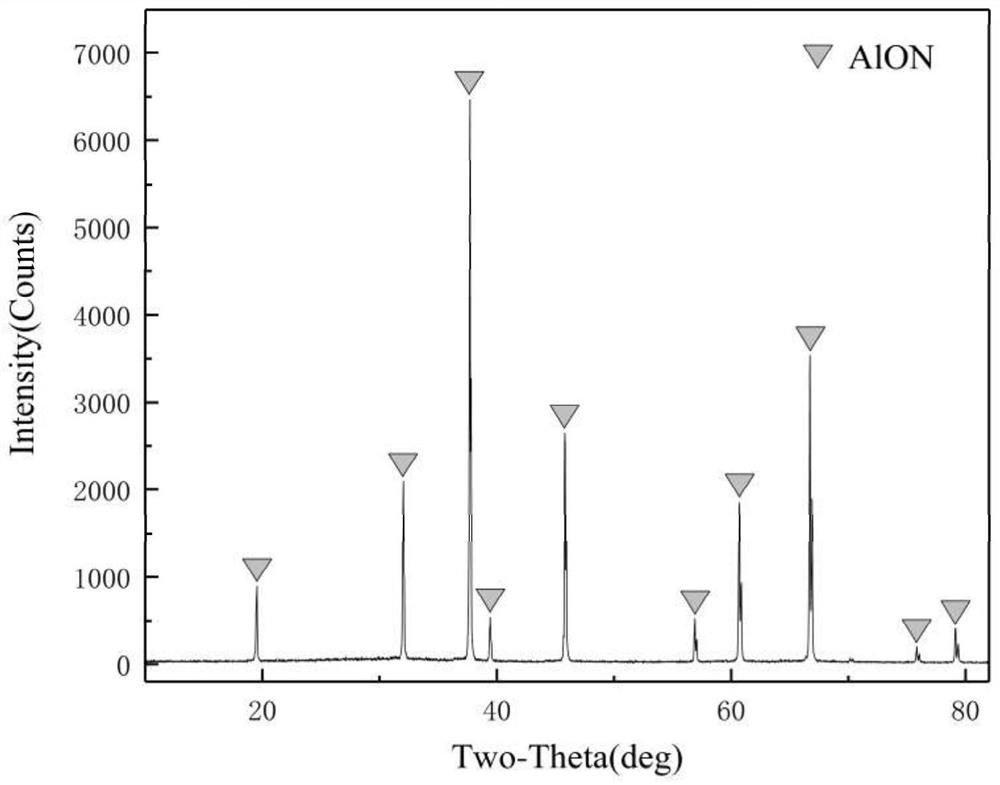

Embodiment 1

[0036] Step 1) Powder mixing

[0037] The molar ratio is 60 mol%: 40 mol% of the γ-Al 2 O 3 Powder (purity 99.99%, particle size 50 nm) and AlN powder (purity 99.99%, particle size 50 nm), sintering auxiliary (0.08 wt% Y 2 O 3 +0.2wt%MgO+0.08wt%La 2 O 3 ), in 3mm, 8mm, 10mm high purity Al 2 O 3 The ball is a ball mill medium, the ball material ratio is 3:1, and absolute ethanol is added as the dispersion medium, which is put into the nylon tank together, and the ball mill is milled at a speed of 100r / min for 30h using a full-range planetary ball mill.

[0039]The powder is dried by a rotary evaporator, and the dried powder is ground and passed through a 200 mesh sieve to obtain a uniformly dispersed mixed powder.

[0040] Step 3) Mold Loading: Load the dried mixed powder into the graphite mold. For better demolding, 1 to 2 layers of graphite paper need to be cushioned between the powder and the graphite mold; in order to prevent heat loss during the ...

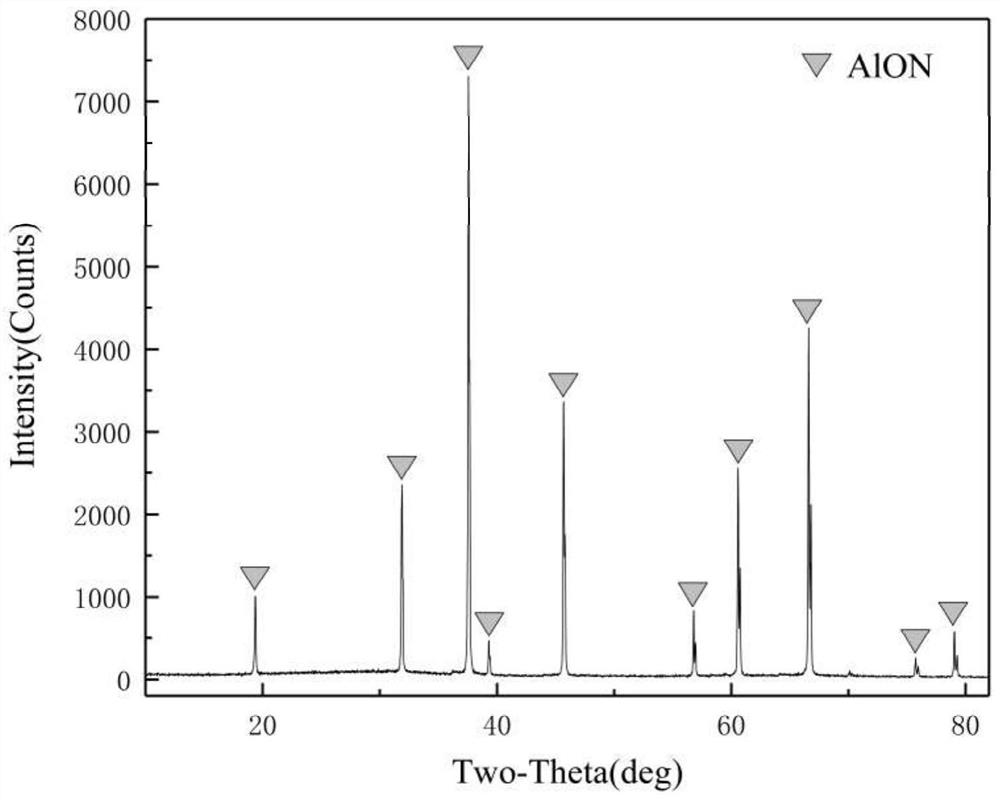

Embodiment 2

[0050] Step 1) Powder Mixing:

[0051] The molar ratio is 64.3 mol%: 35.7 mol% of γ-Al 2 O 3Powder (purity 99.99%, particle size 20 nm) and AlN powder (purity 99.99%, particle size 50 nm), sintering aid (0.12 wt%Y 2 O 3 +0.3wt%MgO+0.04wt%La 2 O 3 ) to 3mm, 8mm, 10mm high purity Al 2 O 3 The ball is a ball mill medium, the ball material ratio is 4:1, and anhydrous ethanol is added as the dispersion medium, which is put into the nylon tank together, and the ball mill is milled at a speed of 150r / min for 20h using a full-range planetary ball mill.

[0052] Step 2) Same as Example 1

[0053] Step 3) Same as Example 1.

[0054] Step 4) Discharge plasma sintering:

[0055] Put the installed mold into the furnace chamber of the discharge plasma sintering furnace, start sintering after the vacuum degree is less than 20Pa, rise to 1580 °C at a heating rate of 150 °C / min, and cool with the furnace after 10 min of insulation, and the pressure during the sintering process is 50MPa.

[0056] S...

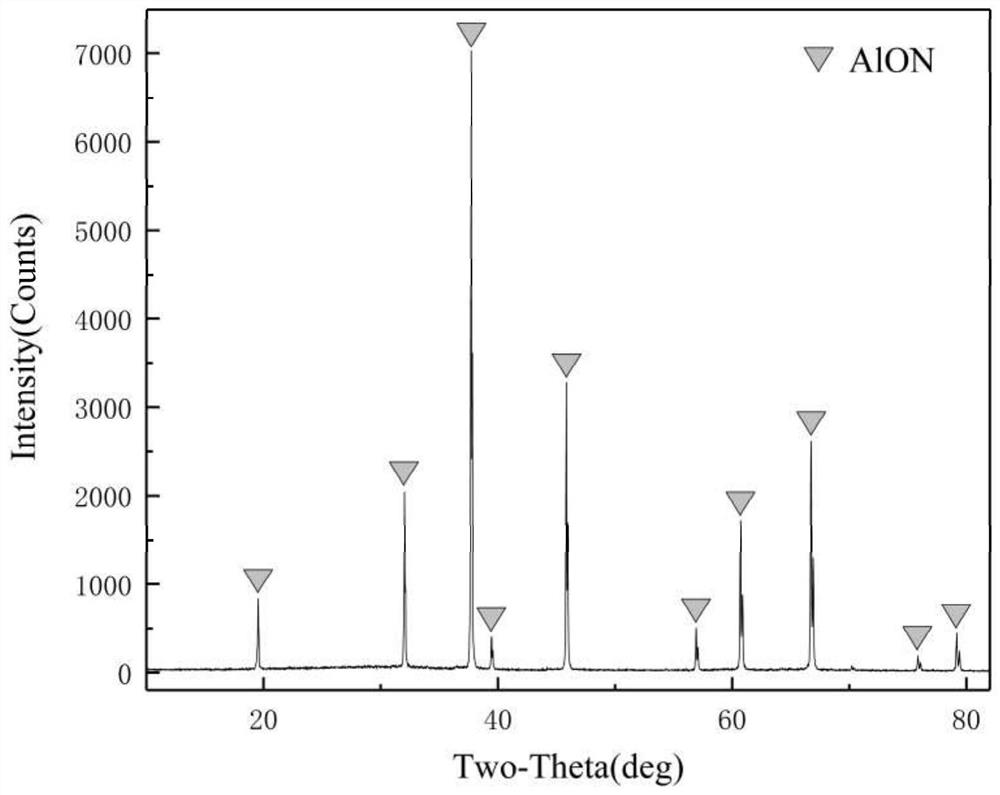

Embodiment 3

[0064] Step 1) Powder Mixing:

[0065] The molar ratio is 64.3 mol%: 35.7 mol% of γ-Al 2 O 3 Powder (purity 99.99%, particle size 20 nm) and AlN powder (purity 99.99%, particle size 50 nm), sintering auxiliary (0.16 wt%Y 2 O 3 +0.4wt%MgO+0.08wt%La 2 O 3 ) to 3mm, 8mm, 10mm high purity Al 2 O 3 The ball is a ball mill medium, the ball-to-material ratio is 5:1, and absolute ethanol is added as the dispersion medium, which is put into the nylon tank together, and the ball mill is ground at a speed of 200r / min for 10h using an all-round planetary ball mill.

[0066] Step 2) Same as Example 1

[0067] Step 3) Same as Example 1.

[0068] Step 4) Discharge plasma sintering:

[0069] The installed mold is put into the discharge plasma sintering furnace chamber, vacuum to vacuum less than 20Pa after the start of sintering, at a temperature rate of 200 °C / min to 1600 °C, heat preservation for 5 min with the furnace cooling, sintering process pressure of 60MPa.

[0070] Step 5) Decarboniza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com