MOFs conductive polymer composite film gas sensor and preparation method thereof

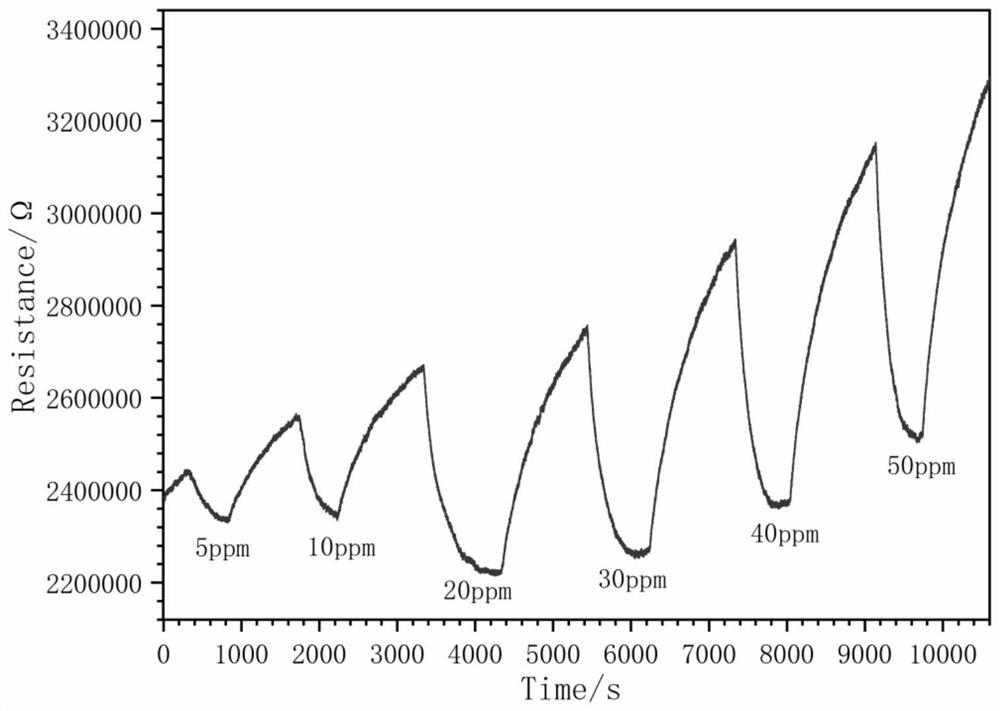

A technology of gas sensors and conductive polymers, which can be used in instruments, scientific instruments, air quality improvement, etc., can solve the problems of poor conductivity of MOFs and achieve excellent gas sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

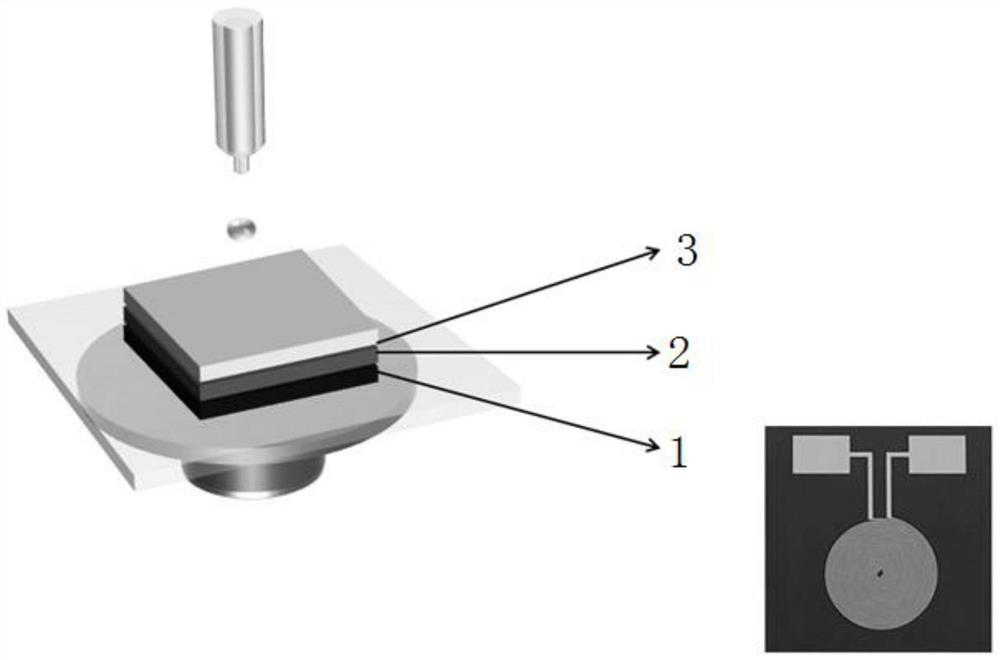

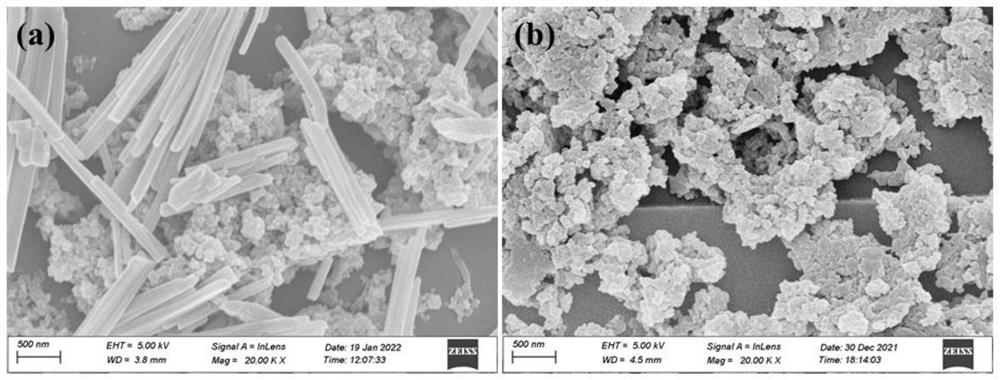

[0058] This embodiment provides a preparation method of a MOFs conductive polymer composite thin film gas sensor. Poly-3,4-ethylenedioxythiophene PEDOT is deposited on the surface of gold interdigitated electrodes, and cobalt nitrate hexahydrate, cerium nitrate hexahydrate and trimesic acid are used. Formic acid was used as raw material to synthesize cobalt-cerium-based metal organic framework CoCe-BTC by water bath method, and then spin coating method was used to obtain CoCe-BTC / PEDOT composite film.

Embodiment 2

[0060] The present embodiment provides a preparation method of a MOFs conductive polymer composite thin film gas sensor, comprising the following steps:

[0061] S1, using cobalt nitrate hexahydrate, cerium nitrate hexahydrate and trimesic acid as raw materials to synthesize cobalt-cerium-based metal organic framework CoCe-BTC by a water bath method;

[0062] S2, cleaning and preprocessing the silicon oxide substrate, and then preparing gold interdigitated electrodes on the surface;

[0063] S3. Spin-coat poly-3,4-ethylenedioxythiophene PEDOT on the interdigitated electrode obtained in step S2, and place it on a hot table to dry;

[0064] S4. Spin-coat the cobalt-cerium-based metal organic framework CoCe-BTC on the interdigitated electrode obtained in step S3, and put it on a hot table to dry, to obtain a gas sensor with a MOFs conductive polymer composite film CoCe-BTC / PEDOT.

Embodiment 3

[0066] The present embodiment provides a preparation method of a MOFs conductive polymer composite thin film gas sensor, comprising the following steps:

[0067] (1) S1, using cobalt nitrate hexahydrate, cerium nitrate hexahydrate and trimesic acid as raw materials to synthesize cobalt-cerium-based metal organic framework CoCe-BTC by a water bath method;

[0068] Specifically, step S1 specifically includes the following steps:

[0069] S101, a certain proportion of cobalt nitrate hexahydrate and cerium nitrate hexahydrate are dissolved in the first solvent successively, and fully stirred to form a uniform mixed solution;

[0070] Preferably, in step S101, the molar ratio of cobalt nitrate hexahydrate and cerium nitrate hexahydrate is 1:10;

[0071] Preferably, the first solvent in step S101 is deionized water for dissolving cobalt nitrate hexahydrate and cerium nitrate hexahydrate;

[0072] S102, a certain amount of trimesic acid is dissolved in the second solvent, and fully...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com