Cathode active material, method for preparing same, and lithium secondary battery comprising same

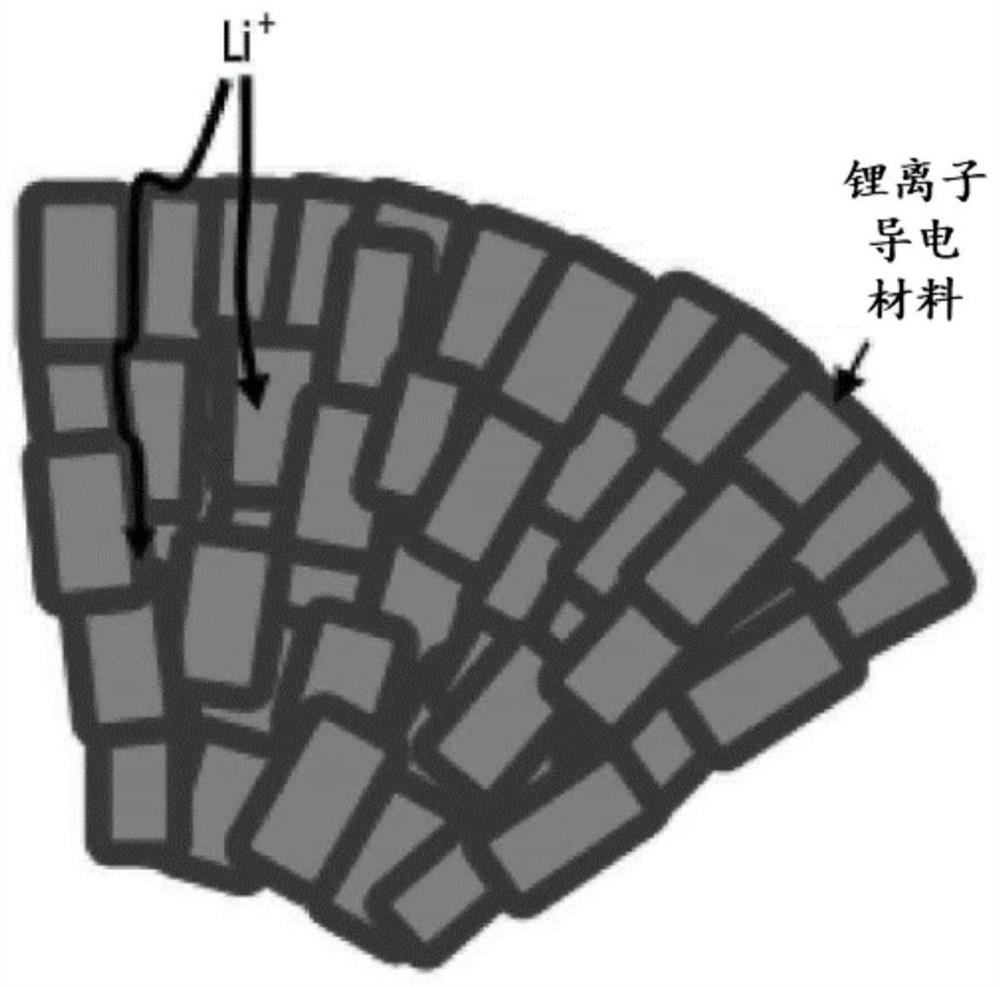

A cathode active material, secondary particle technology, applied in secondary batteries, lithium storage batteries, battery electrodes, etc., to improve high temperature increase rate characteristics, increase particle strength, and inhibit side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Another embodiment of the present invention provides a method for preparing a positive electrode active material, comprising: a step of preparing a coating-forming substance; a step of adding an aqueous metal salt solution to a coprecipitation reactor to obtain a metal precursor; and The step of calcining the coating-forming substance, the metal precursor and the lithium raw material after mixing to obtain a positive electrode active material.

[0056] In particular, in this embodiment, the coating-forming substance may be provided in the form of a microparticulate powder. For example, the average particle diameter (D50) of the microparticulate powder may be 0.1 μm to 1.5 μm, and more specifically, 0.3 μm to 1 μm.

[0057] More specifically, the step of preparing the coating-forming substance includes a step of calcining after mixing raw materials constituting the boron compound, and a step of pulverizing the calcined calcined product. At this time, for example, the st...

preparation example 1

[0090] (Preparation Example 1) - Preparation of coating-forming substance and confirmation of properties

[0091] Weigh LiOH·H, the raw material of boron compound, in stoichiometric ratio 2 O and H 3 BO 3 Mixing was performed, followed by calcination at 600°C for 4 hours for synthesis.

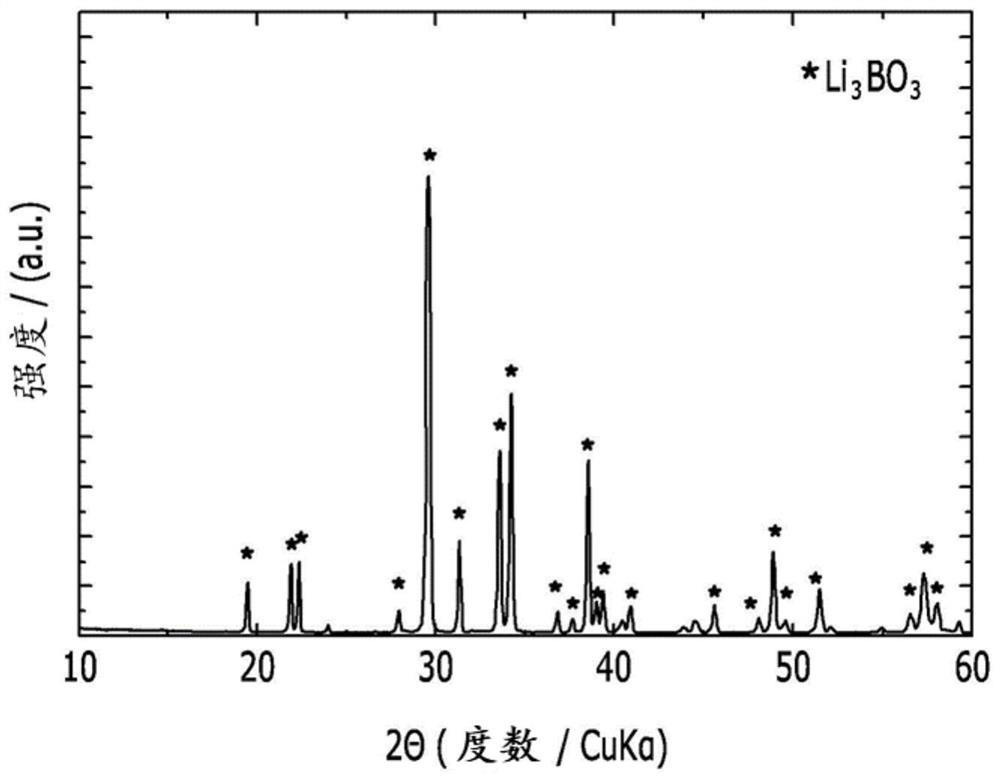

[0092] figure 2 XRD results of the coating-forming substances prepared according to Preparation Example 1 are shown in . from figure 2 It is known that Li 3 BO 3 The phase is well formed as a crystal structure.

[0093] The coating-forming substance synthesized as above was pulverized into an average particle diameter of 0.5 μm to 0.7 μm by a bead mill to prepare a material having Li 3 BO 3 A coating of components forms a substance.

[0094] The coating-forming substances prepared as above were subjected to characteristic tests by the following methods.

[0095] After the synthesized coating-forming substance powder was formed into pellets having a diameter of 10 mm, heat treatmen...

Embodiment 1

[0098] (Example 1) Preparation containing 0.005 moles of Li 3 BO 3 The Ni is 71 mol% for the large particle size cathode active material

[0099] 1) Preparation of cathode active material precursors

[0100] NiSO is used as nickel raw material 4 ·6H 2 O, CoSO is used as cobalt raw material 4 ·7H 2 O, MnSO was used as manganese raw material 4 ·H 2 O. These raw materials were dissolved in distilled water to prepare a 2.5M aqueous metal salt solution.

[0101] After preparing the co-precipitation reactor, in order to prevent the oxidation of metal ions during the co-precipitation reaction, use N 2 Purging was carried out and the reactor temperature was maintained at 50°C.

[0102] A metal salt aqueous solution and NH as a chelating agent are added to the coprecipitation reactor 4 (OH). In addition, for pH adjustment, NaOH was used. The precipitate obtained according to the coprecipitation process was filtered, washed with distilled water, and dried in an oven at 100°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com