Polysulfone blend membrane with low block copolymer content and preparation method thereof

A technology of block copolymer and blend membrane, which is applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of increasing membrane production cost and high synthesis cost, and achieves reduction of preparation cost, optimization of stirring speed, increase of The effect of the anchor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

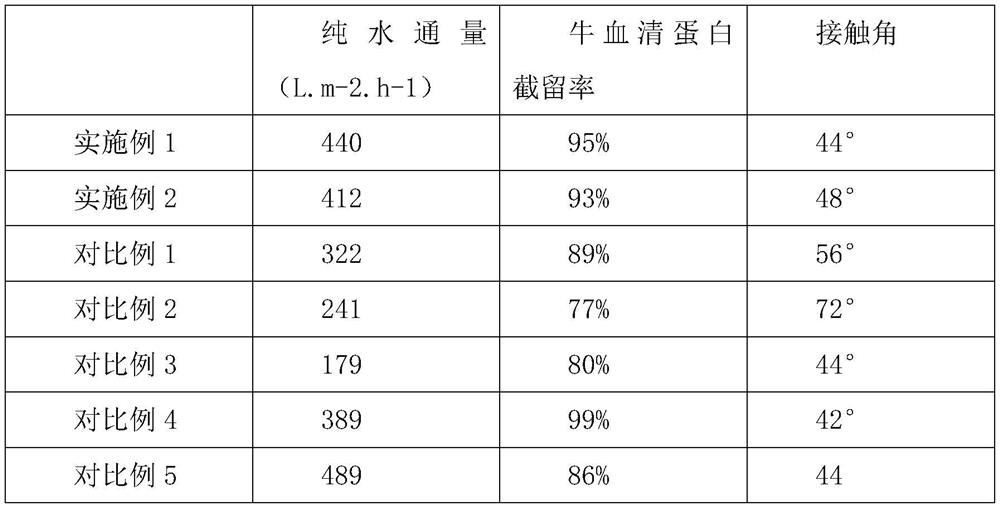

Examples

Embodiment 1

[0026] This embodiment adopts the following steps to prepare polysulfone ultrafiltration membrane:

[0027] (a) 10g of polysulfone, 0.05g of PSf-b-PEG block copolymer (the ratio of its PSF segment to PEG segment is 4:1), and 2g of PEG with a molecular weight of 4000 were dissolved in 50g of dimethyl ether in turn A mixed solution was formed in the base formamide, and the thermal cross-linking was stirred at a cross-linking temperature of 100 °C for 2 h, and the stirring speed was 50 r / min;

[0028] (b) cooling the mixed solution to room temperature, adding 4 g of PEG with a molecular weight of 1000 to the mixed solution, stirring evenly, standing, and defoaming to form a casting solution;

[0029] (c) Scrape the casting liquid evenly on a glass plate to form a certain thickness, and place it in a 60°C coagulation bath that is mixed with dimethylformamide and water in a volume of 3:7 for phase conversion, and then take out and soak in In deionized water for 0.5 h, and then dri...

Embodiment 2

[0031] This example uses the following steps to prepare a polysulfone membrane:

[0032] (a) 10 g of polysulfone, 0.05 g of PSf-b-PEG block copolymer (the ratio of its PSF segment to PEG segment is 2:1), and 2 g of PEG with a molecular weight of 4000 were dissolved in 50 g of dimethyl ether in turn. A mixed solution was formed in the base formamide, and the thermal cross-linking was stirred at a cross-linking temperature of 100 °C for 2 h, and the stirring speed was 50 r / min;

[0033] (b) cooling the mixed solution to room temperature, adding 4 g of PEG with a molecular weight of 1000 to the mixed solution, stirring evenly, standing, and defoaming to form a casting solution;

[0034] (c) Scrape the casting liquid evenly on a glass plate to form a certain thickness, and place it in a 60°C coagulation bath that is mixed with dimethylformamide and water in a volume of 3:7 for phase conversion, and then take out and soak in In deionized water for 0.5 h, and then dried in an oven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com