Preparation method of lightweight high-shielding PA6/PS composite foam

A composite foam and lightweight technology, applied in the field of electromagnetic shielding, can solve the problems of secondary pollution of electromagnetic waves, single structure of shielding materials, no structural design, etc., and achieve the effect required by high shielding effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of light-weight and high-shielding PA6 / PS composite foam

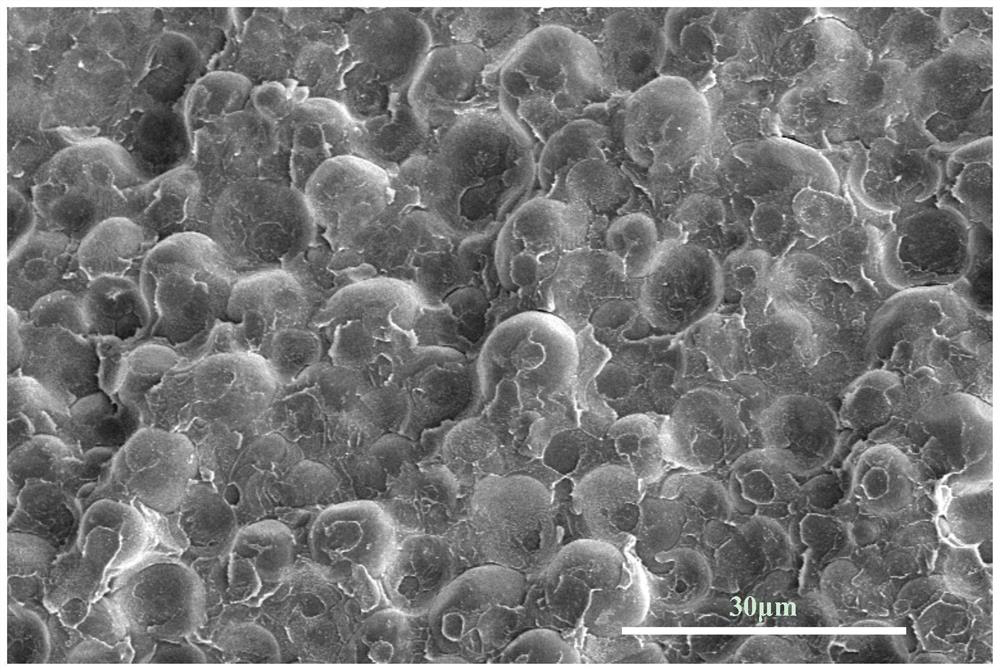

[0028] Add 15g PS to 85g molten caprolactam monomer at 110°C and stir mechanically for 3.5h to obtain CL / PS suspension. Put the suspension in a heating mantle at 160°C for 30 minutes to remove water under vacuum, add 0.4g NaOH, continue to remove water for 30 minutes, add 0.4g TDI, shake vigorously quickly and pour it into a mold at 180°C for polymerization for 40 minutes to obtain PA6 / PS alloy. Use a high-speed pulverizer to pulverize the PA6 / PS alloy to obtain the first mixed powder; add 5g of carbon black (CB) to the first mixed powder and mix at a high speed for 3 minutes to obtain the second mixed powder; put the second mixed powder in In a specific mold, use a fully automatic tablet press to mold the mixed powder. The molding temperature is 200°C, the time is 10min, and the pressure is 10MPa to obtain a PA6 / PS / CB composite material.

Embodiment 2

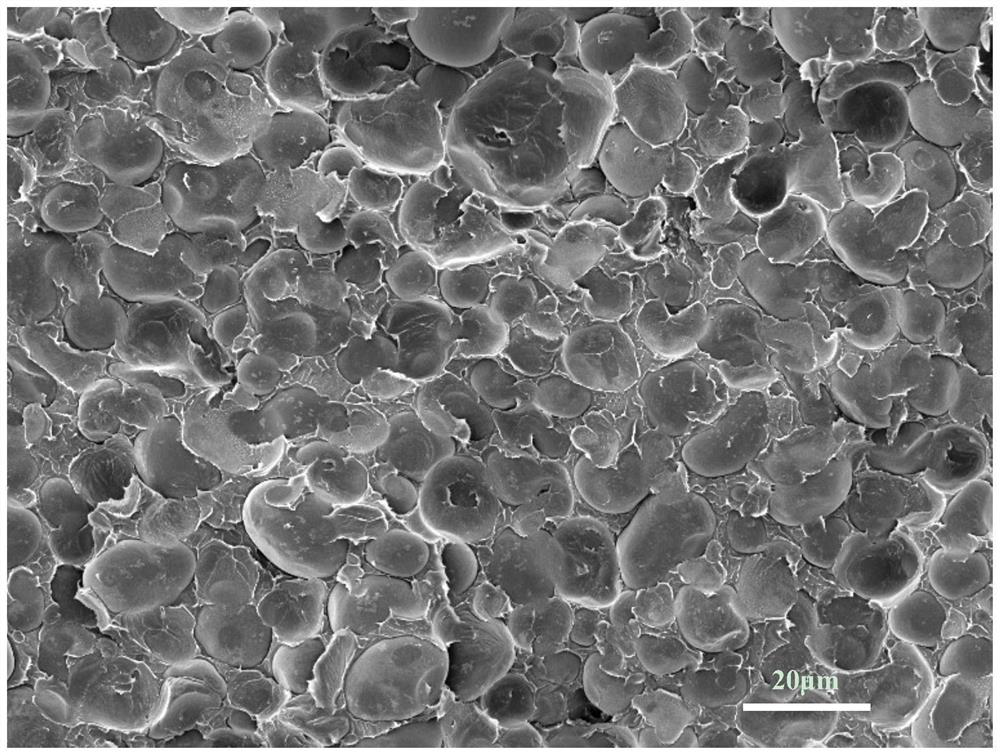

[0030] Add 15g PS to 85g molten caprolactam monomer at 110°C and stir mechanically for 3.5h to obtain CL / PS suspension. Put the suspension in a heating mantle at 160°C for 30 minutes to remove water under vacuum, add 0.4g NaOH, continue to remove water for 30 minutes, add 0.4g TDI, shake vigorously quickly and pour it into a mold at 180°C for polymerization for 40 minutes to obtain PA6 / PS alloy. Use a high-speed pulverizer to pulverize the PA6 / PS alloy to obtain the first mixed powder; add 5g of CB to the first mixed powder and mix at high speed for 3 minutes to obtain the second mixed powder; put the second mixed powder into a specific mold, Use a fully automatic tablet press to mold the mixed powder. The molding temperature is 200°C, the time is 10min, and the pressure is 10MPa to obtain a PA6 / PS / CB composite material; use a foaming kettle to mold the PA6 / PS / CB composite material Supercritical CO 2 For foaming treatment, the foaming temperature is 80°C, the pressure holding...

Embodiment 3

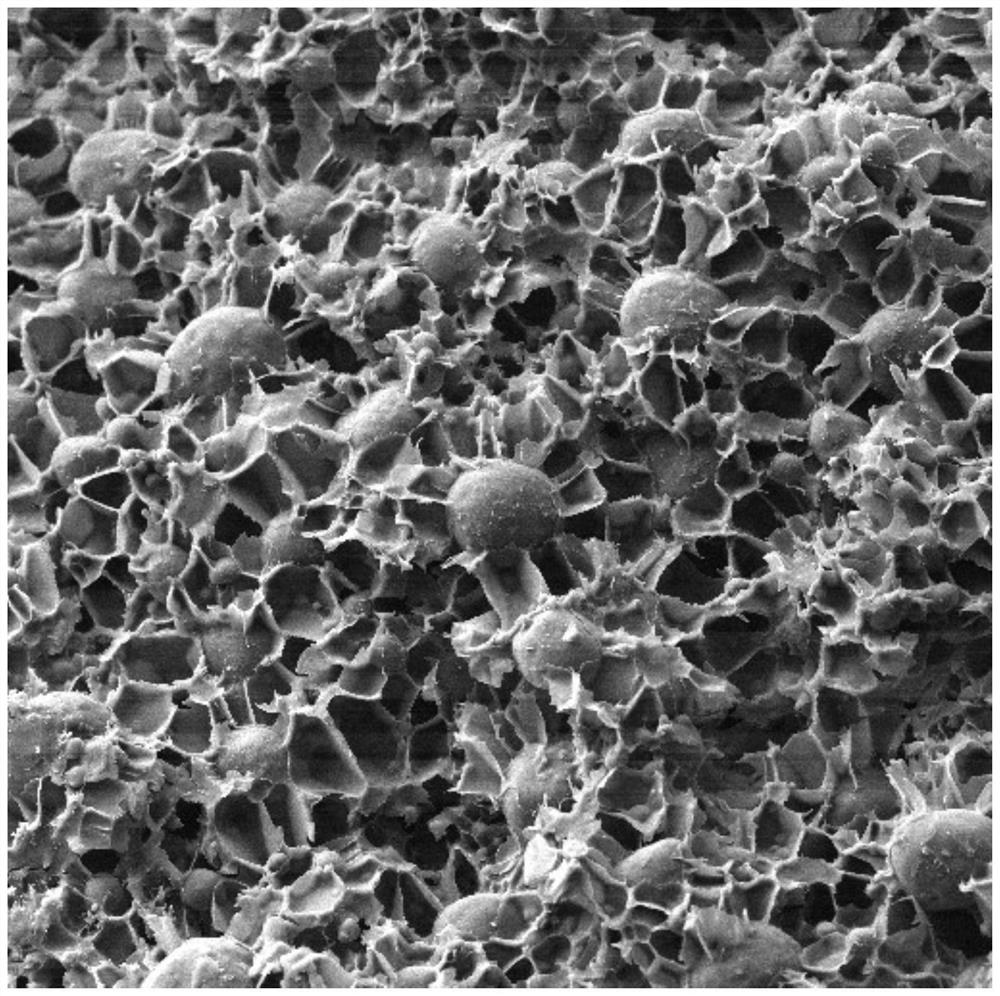

[0032]Add 15g PS to 85g molten caprolactam monomer at 110°C and stir mechanically for 3.5h to obtain CL / PS suspension. Put the suspension in a heating mantle at 160°C for 30 minutes to remove water under vacuum, add 0.4g NaOH, continue to remove water for 30 minutes, add 0.4g TDI, shake vigorously quickly and pour it into a mold at 180°C for polymerization for 40 minutes to obtain PA6 / PS alloy. Use a high-speed pulverizer to pulverize the PA6 / PS alloy to obtain the first mixed powder; add 5g of MWCNT to the first mixed powder and mix at high speed for 3 minutes to obtain the second mixed powder; put the second mixed powder into a specific mold, The mixed powder was molded with a fully automatic tablet press at a temperature of 200° C. for 10 minutes and a pressure of 10 MPa to obtain a PA6 / PS / MWCNT composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com