Method for removing silicon dioxide from high-salt printing and dyeing wastewater

A technology of printing and dyeing wastewater and silica, which is applied in chemical instruments and methods, energy wastewater treatment, water/sewage treatment, etc., can solve the problems of high cost and no specific solution, and achieve low hardness, cost reduction, good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

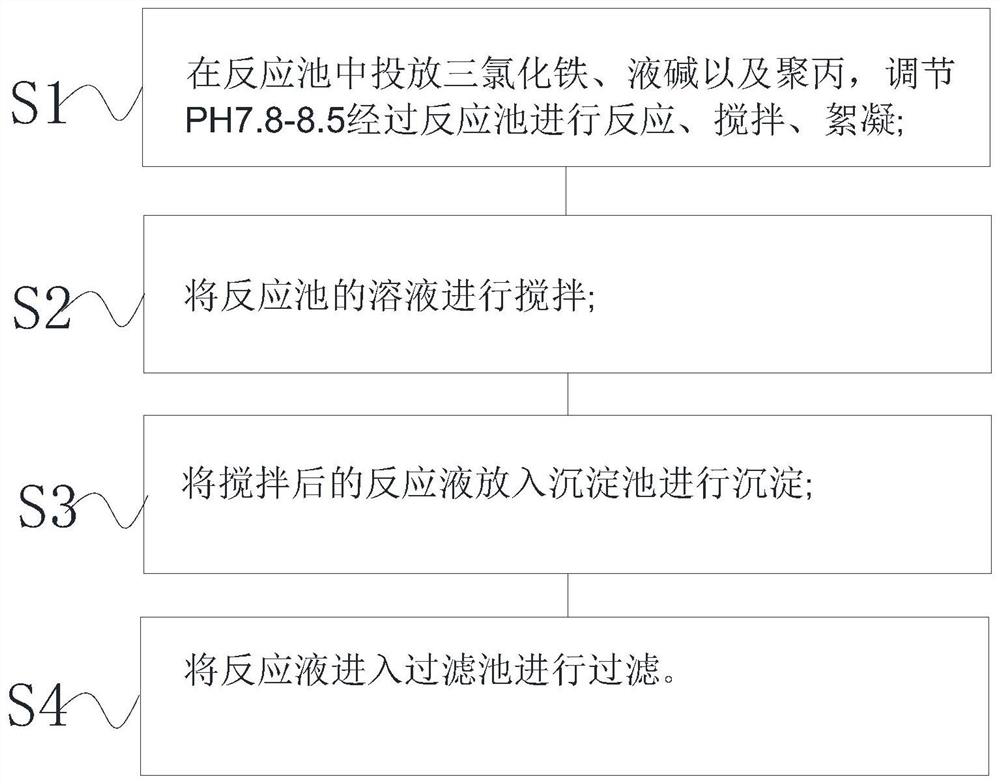

[0025] A method for removing silicon dioxide from high-salt printing and dyeing wastewater, comprising the following steps:

[0026] S1. Put ferric chloride, liquid caustic soda and polypropylene in the reaction tank, adjust the pH to 7.8-8.5 and go through the reaction tank for reaction, stirring and flocculation;

[0027] S2, stirring the solution in the reaction tank;

[0028] S3, put the stirred reaction solution into a sedimentation tank for precipitation;

[0029] S4, enter the reaction solution into the filter tank for filtration.

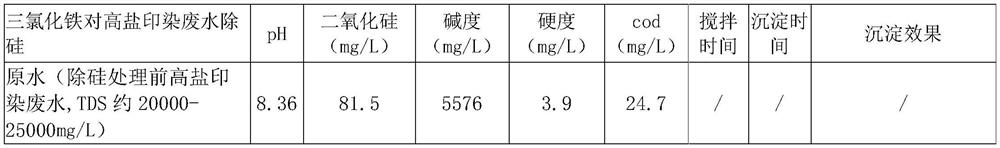

[0030] Specifically, as figure 1 As shown, the high-salt and high-silicon printing and dyeing wastewater (sodium chloride solution, water quality index: TDS about 20000-25000mg / L, SiO 2 The solution of about 80mg / L, PH about 8.3) is added to the reaction tank and put into ferric chloride, liquid caustic soda and polypropylene, and the pH is adjusted to 7.8 to react through the reaction tank; after the reaction and stirring, flocculation i...

Embodiment 2

[0033] The high-salt and high-silicon printing and dyeing wastewater in the reaction tank (sodium chloride solution, water quality indicators: TDS about 20000-25000mg / L, SiO 2 The solution of about 80mg / L, pH about 8.3) was added into the reaction tank and put into ferric chloride, liquid caustic soda and polypropylene, and adjusted the pH to 8.0 to react through the reaction tank; after the reaction and stirring, flocculation was generated, and the stirred reaction solution After being put into the inclined tube tank for precipitation and the reaction liquid was filtered, the SiO in the high-salt and high-silicon printing and dyeing wastewater in the reaction tank 2 The content can be controlled at 37.7mg / L; at the same time, the hardness will not increase significantly, and the content of heavy metals such as iron ions in the water will not increase significantly.

[0034] Further, in step S1, a stirring device is provided in the reaction tank, and the stirring device is use...

Embodiment 3

[0036] The high-salt and high-silicon printing and dyeing wastewater in the reaction tank (sodium chloride solution, water quality indicators: TDS about 20000-25000mg / L, SiO 2 The solution of about 80mg / L, PH about 8.3) is added into the reaction tank and put into ferric chloride, liquid caustic soda and polypropylene, and the pH is adjusted to 8.5 to react in the reaction tank; after the reaction and stirring, flocculation is generated, and the stirred reaction solution After being put into the inclined tube tank for precipitation and the reaction liquid was filtered, the SiO in the high-salt and high-silicon printing and dyeing wastewater in the reaction tank 2 The content can be controlled at 21.9mg / L; at the same time, the hardness will not increase significantly, and the content of heavy metals such as iron ions in the water will not increase significantly.

[0037] Further, the S3 reaction solution is put into the inclined tube pool and the reaction solution in S4 is put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com