Method for performing sulfur-doped phosphorus modification on carbon surface and application thereof

A sulfur doping, carbon surface technology, applied in structural parts, electrochemical generators, electrode manufacturing, etc., can solve problems such as poor affinity between phosphorus and negative electrode materials, improve environmental stability, simple process, and low raw material cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

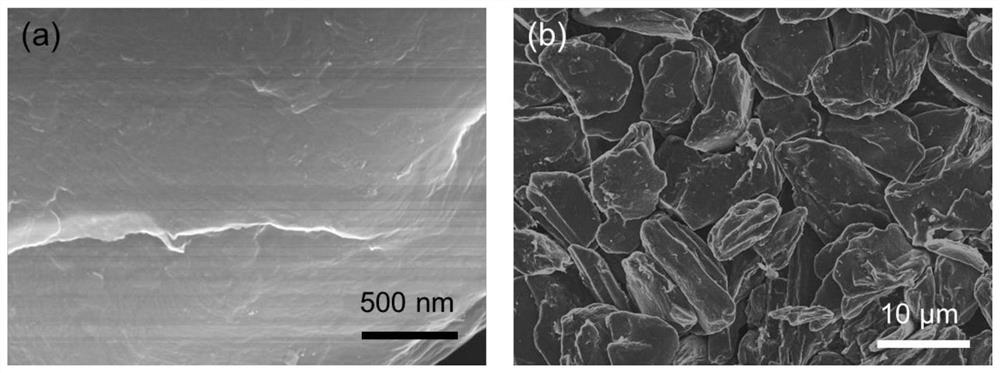

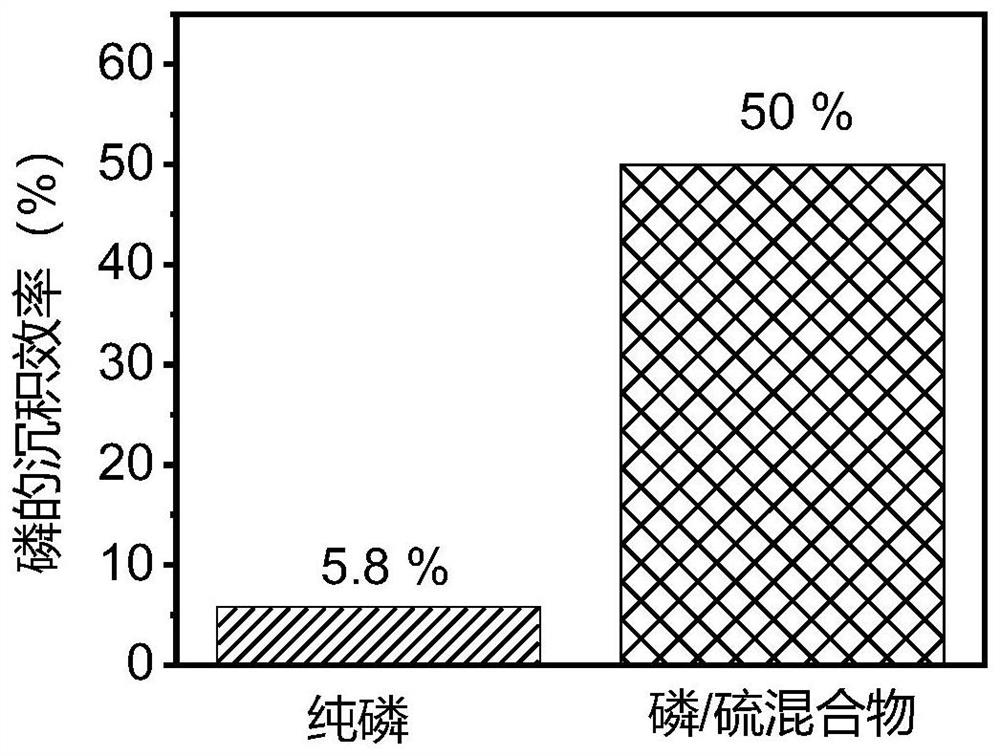

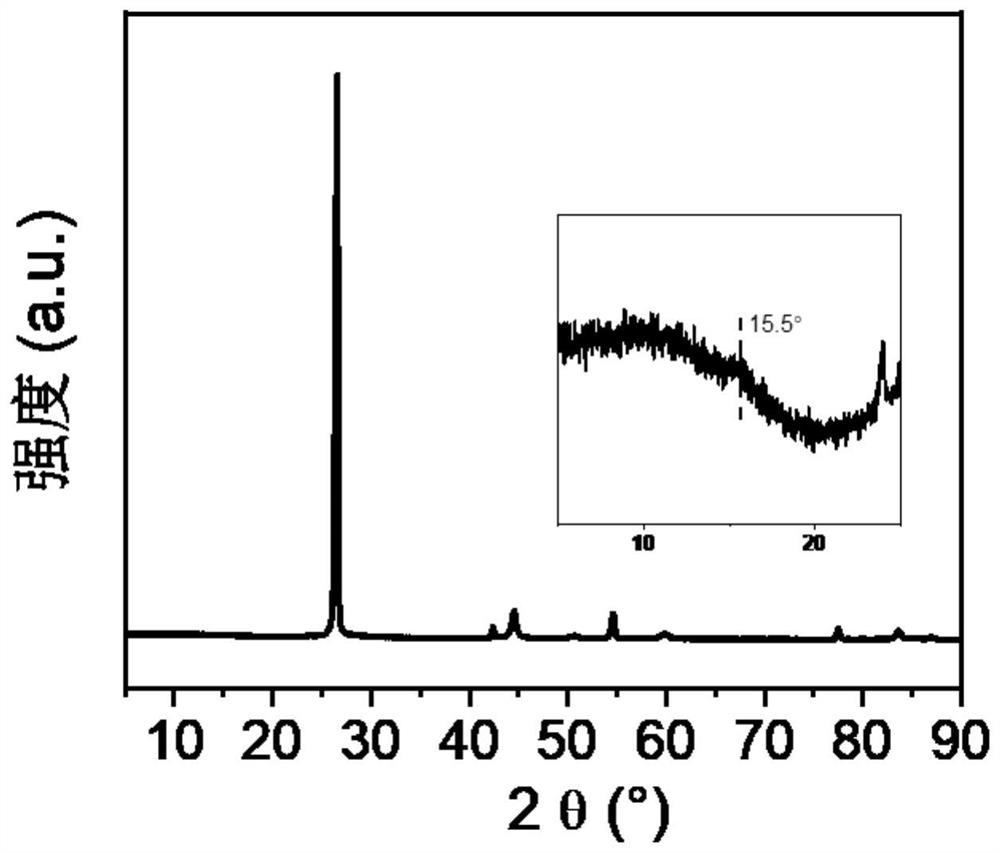

[0046] In this embodiment, the high-performance negative electrode material with a sulfur-doped phosphorus interface layer has a chemical composition of: sulfur, red phosphorus, and hard carbon-coated graphite (provided by Huawei). The hard carbon-coated graphite is coated with sulfur-doped red phosphorus. The preparation process of the negative electrode material is to first prepare a sulfur-phosphorus mixed material, and then use the sulfur-phosphorus mixed material as an evaporation source to make the sulfur-phosphorus mixed material and hard carbon-coated graphite composite; in the preparation process, the ratio of raw materials: the mass of sulfur accounts for sulfur 1% of the total mass of the phosphorus mixed material, and the mass ratio of the sulfur-phosphorus mixed material to the hard carbon-coated graphite is 3:97.

[0047] The specific operation steps are as follows:

[0048] (1) Preparation of hard carbon-coated graphite composites with sulfur-doped phosphorus i...

Embodiment 2

[0067] The method for preparing a hard carbon-coated silicon composite material with a sulfur-doped phosphorus interface layer provided in this embodiment, except that the material used in step (1) is hard carbon-coated silicon (the mass ratio of the hard carbon layer to the silicon is 3:7) composite material, and the remaining steps are the same as in Example 1.

Embodiment 3

[0069] The present embodiment provides a method for preparing a hard carbon-coated silicon oxide composite material with a sulfur-doped phosphorus interface layer, except that the material used in step (1) is a hard carbon-coated silicon oxide (hard carbon layer and The mass ratio of silicon oxide is 3:7) composite material, and the remaining steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com