Functional dietary fiber used in cooperation with premixed feed and preparation method of functional dietary fiber

A premixed feed and functional fiber technology, applied in the field of feed, can solve the problems of high toxins and single fiber raw materials, and achieve the effects of improving production performance, facilitating the use of ingredients, and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the invention comprises the following steps: processing two kinds of fiber raw materials, sugarcane bagasse and poplar, to obtain corresponding fiber semi-finished products, then mixing the two fiber semi-finished products in a certain proportion, granulating, and crushing to obtain irregular flake particles. In the production process of premixed feed for pig farms, due to the light specific gravity of powdered raw materials and the large volume of materials, there is a lot of dust when mixing the ingredients, and it is prone to stratification, resulting in uneven mixing. Therefore, it is necessary to further compress and granulate the powdered fiber with low specific gravity to ensure the convenience of the pig farm's ingredients and the uniformity of the feed. A detailed description will be given below.

[0042] step 1)

[0043] In step (1) of the present invention, bagasse raw materials and wood raw materials are collected, wherein the ra...

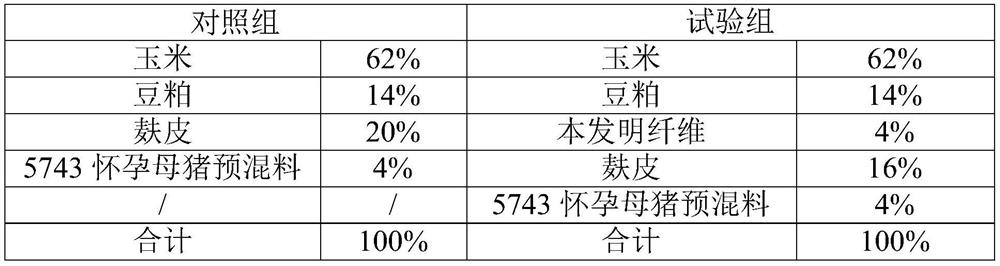

Embodiment 1

[0060] The present embodiment is the preparation method of functional fiber and its application on sow, and the specific method is as follows:

[0061] 1. Processing of bagasse

[0062] (1) Alkali treatment: The bagasse is mixed with a 2% mass fraction of sodium hydroxide solution (99% purity) in a weight: volume ratio of 1:2, the temperature of the solution is 30°C, and the soaking time is 2 hours , and then soaked in tap water with a temperature of 30 ° C for 1 hour, and then washed.

[0063] (2) Steam flash explosion: put the bagasse into the flash chamber through the feeding barrel, increase the pressure of the flash chamber to 2MPa through the pressurizing valve, and then blast for 1min. , The elevator is used for grinding to a ball mill pulverizer, and the crushing particle size is more than 90% and passes through a 20-mesh sieve to obtain a semi-finished product of bagasse fiber.

[0064] 2. Treatment of poplar

[0065] (1) Primary powder of trees: peel the trees, wa...

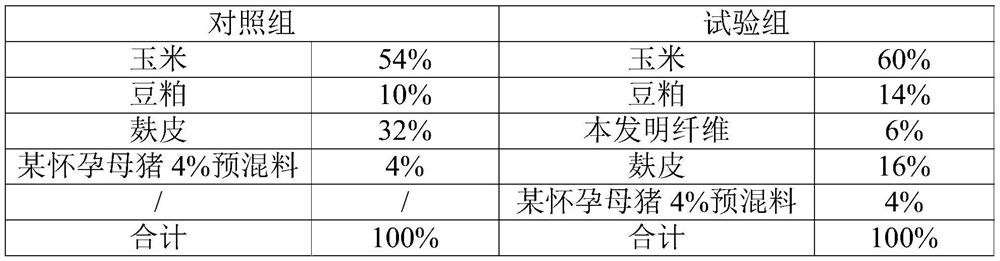

Embodiment 2

[0085] The present embodiment is a preparation method of functional fiber and its application on sows, and the specific method is as follows:

[0086] 1. Processing of bagasse

[0087] (1) Alkali treatment: The bagasse is mixed with a 3% mass fraction of sodium hydroxide solution (99% purity) in a weight: volume ratio of 1:3, the temperature of the solution is 40°C, and the soaking time is 2 hours , and then soaked in tap water with a temperature of 40 ° C for 1 hour, and then washed.

[0088] (2) Steam flash explosion: put the bagasse into the flash chamber through the feeding barrel, increase the pressure of the flash chamber to 2MPa through the pressurizing valve, and then blast for 1min. , Elevator to ball mill pulverizer for pulverization, and the pulverization particle size is more than 90% and passes through a 20-mesh sieve.

[0089] 2. Treatment of poplar

[0090] (1) Primary powder of trees: peel the trees, wash with tap water, and then enter the poplar into the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com