Long-life high-resilience liquid silica gel

A liquid silicone, high-rebound technology, applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve problems such as dependence on imports of silicone keys, improve service life and press feel, good thermal conductivity and anti-aging performance, improve Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

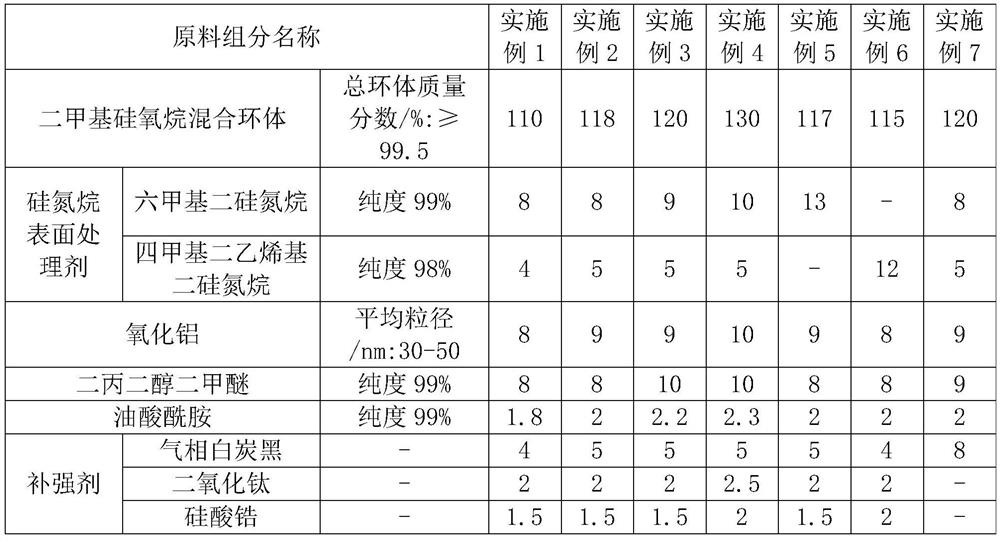

Embodiment 1~7

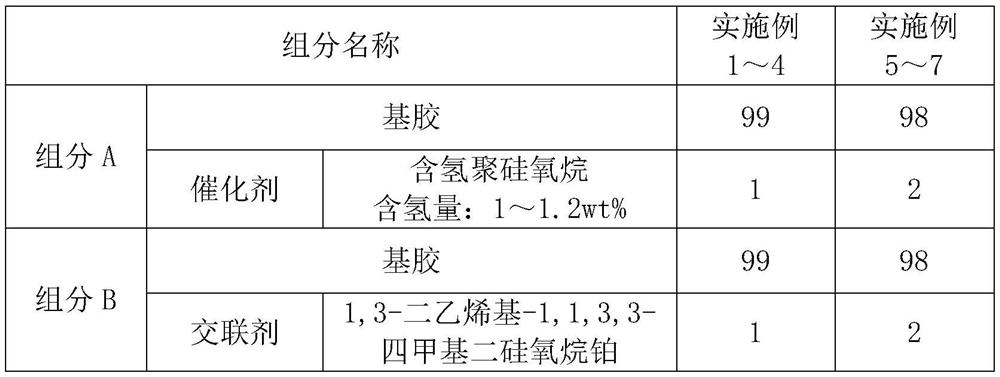

[0039] Step 1) Weigh the dimethicone mixed ring, dipropylene glycol dimethyl ether, oleic acid amide, vacuum stirring treatment in the temperature range of 155 ~ 165 ° C, vacuum pressure of ~0.08 ~ ~ 0.1Mpa, stirring time of 2h, to obtain the base polymer; step 2) weigh the siizolane surface treatment agent, alumina and reinforcing agent, mix with the base polymer, continue heat treatment for 1h, to cool the system after grinding into powder, to obtain the base adhesive;

[0040] Step 3) Weigh the catalyst and the base rubber mixed evenly, vacuum stirring evenly processed, vacuum pressure of ~0.08 ~ 0.1Mpa, stirring time of 30min, filter to obtain A component;

[0041] Step 4) Weigh the crosslinker and the base glue mix evenly, vacuum stirring and even processing, vacuum pressure of ~0.08 ~ 0.1Mpa, stirring time of 30min, filter to obtain B component;

[0042]Step 5) The A component, the B component is mixed uniformly according to the mass ratio of 1: 1 to obtain liquid silica gel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com