Hot melt adhesive for road expansion joints and preparation method thereof

A hot-melt adhesive and expansion joint technology, applied in the field of road and bridge materials, can solve the problems of large smoke, cumbersome feeding, high viscosity of the output and cannot be pumped, achieve excellent flexibility and scalability, reduce construction temperature, high temperature drop Viscous effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

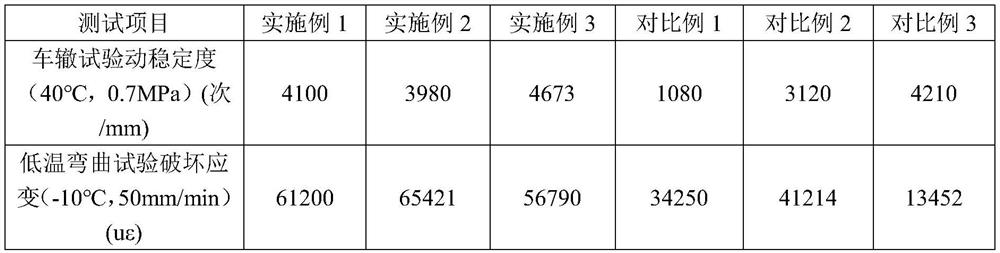

Examples

Embodiment 1

[0042] The hot melt adhesive for road expansion joints provided in this example includes 15 parts of reactive elastomer (elvaloy 4170, DuPont), 25 parts of terpene resin (KD-138A, Henan Jessman Petrochemical), 30 parts of polyurethane Elastomer (self-made), 3 parts polyethylene wax (SN9088D, Qingdao Sino), 10 parts white oil (No. 15, Shandong Jingtai Chemical); 40 parts hard asphalt particles (Luoyang Yuchen type I); polyurethane elastomer contains The following components: 45 parts of polyether polyol (DL2000, Shandong Lanxing), 8 parts of chain extender (ethylene glycol), 30 parts of isocyanate (S2004, Huntsman), 5 parts of olefin alcohol (allyl alcohol).

[0043] The preparation process of polyurethane elastomer is as follows:

[0044] S1 Place 45 parts of polyether polyol and 8 parts of chain extender in the reaction kettle, heat up to 100-120 °C for vacuum dehydration for 30 minutes;

[0045] S2 put 30 parts of isocyanate into the reaction kettle, and react at 100~120℃ f...

Embodiment 2

[0052] The hot melt adhesive for road expansion joints provided in this example includes 15 parts of reactive elastomer (elvaloy 4924, DuPont), 25 parts of terpene resin (KD-1100T, Henan Jessman Petrochemical), 15 parts of polyurethane elastic body (self-made), 3 parts polyethylene wax (SN105A, Qingdao Sino), 7 parts white oil (No. 10, Shandong Jingtai Chemical), 50 parts hard asphalt particles (Luoyang Yuchen type II); polyurethane elastomer contains the following Components: 35 parts of polyether polyol (DL3000, Shandong Lanxing), 5 parts of chain extender (ethylene glycol), 35 parts of isocyanate (S2004, Huntsman), 5 parts of olefin alcohol (allyl alcohol).

[0053] The preparation process of polyurethane elastomer is as follows:

[0054] S1 Place 35 parts of polyether polyol and 5 parts of chain extender in the reaction kettle, heat up to 100-120 °C for vacuum dehydration for 30 minutes;

[0055] S2 put 35 parts of isocyanate into the reaction kettle, and react at 100~120...

Embodiment 3

[0062] The hot melt adhesive for road expansion joints provided in this example includes 25 parts of reactive elastomer (elvaloy 741, DuPont), 20 parts of terpene resin (KD-1315T, Henan Jessman Petrochemical), 25 parts of polyurethane elastic body (self-made), 3 parts polyethylene wax (SN9120, Qingdao Sino), 5 parts white oil (No. 100, Shandong Jingtai Chemical), 60 parts hard asphalt particles (Luoyang Yuchen type I); polyurethane elastomer contains the following Components: 50 parts of polyether polyol (DL1000, Shandong Lanxing), 10 parts of chain extender (ethylene glycol), 40 parts of isocyanate (S2004, Huntsman), 5 parts of olefin alcohol (allyl alcohol).

[0063] The preparation process of polyurethane elastomer is as follows:

[0064] S1 Place 50 parts of polyether polyol and 10 parts of chain extender in the reactor, and heat up to 100-120 °C for vacuum dehydration for 30 minutes;

[0065] S2 put 40 parts of isocyanate into the reaction kettle, and react at 100~120 ℃ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com