Quality detection system for filling infusion bottle production

A detection system and quality detection method technology, applied in the field of product inspection, can solve problems such as low detection efficiency, affecting product quality, and poor color resolution, and achieve the effects of improving system operation efficiency, increasing data access speed, and optimizing data structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

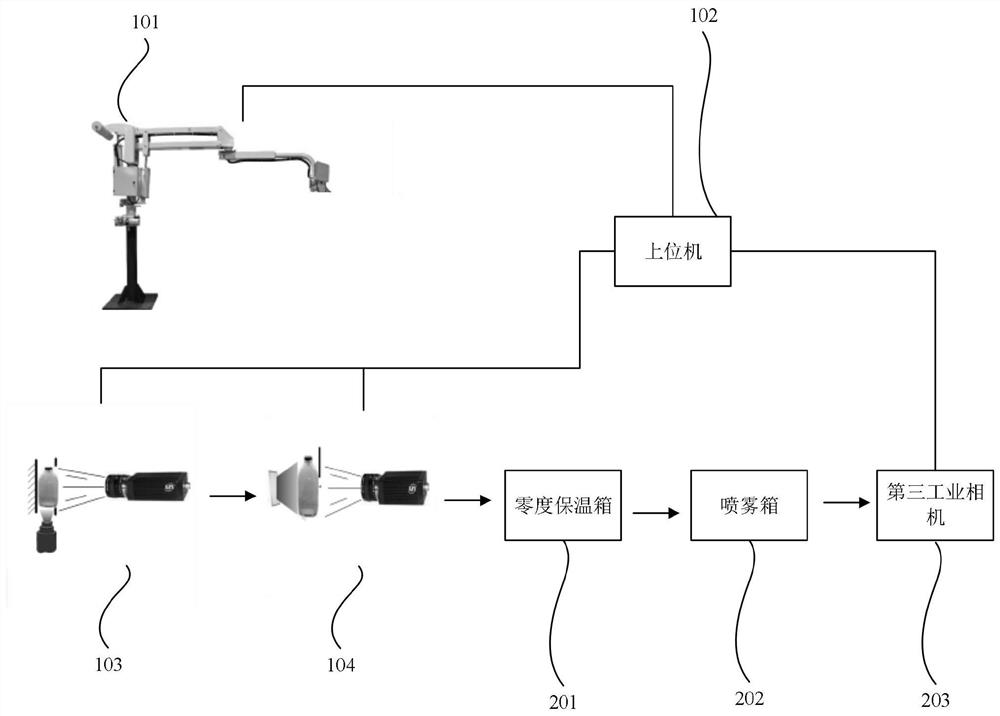

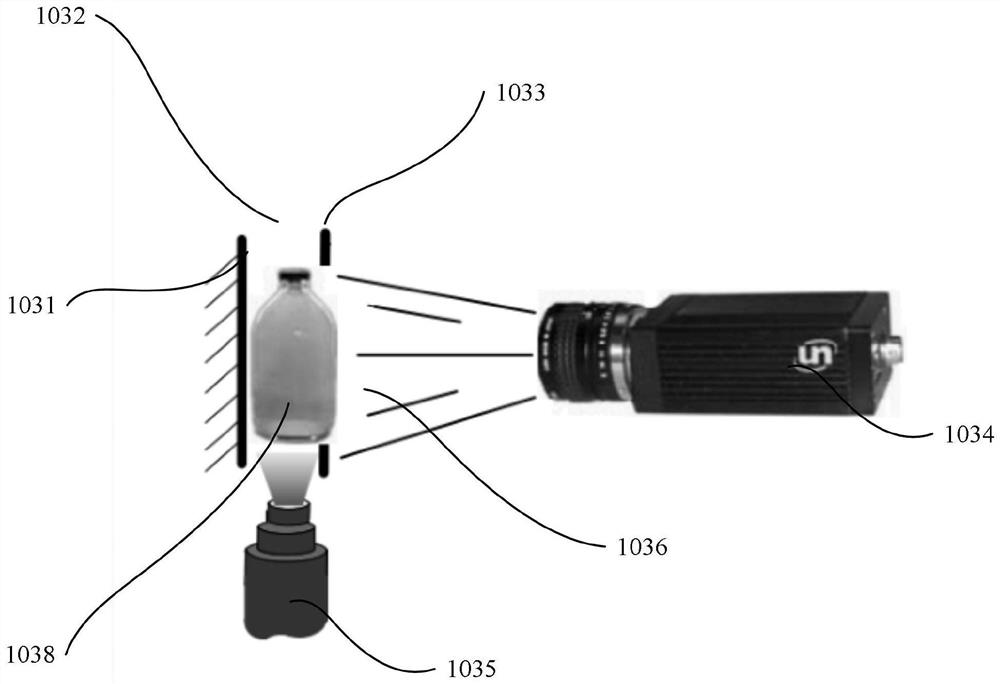

[0055] figure 1 A schematic structural diagram of a defective sorting and rejecting device for filling infusion bottles 1038 provided by the present invention, such as figure 1 As mentioned above, the device includes: a light source, an industrial camera, a robotic arm 101 and a host computer 102, wherein,

[0056] The industrial camera and the robotic arm 101 are respectively connected to the host computer 102 through Gigabit Ethernet; the maximum transmission rate of the Gigabit Ethernet data interface can reach 1000Mb / s, which is much higher than the transmission rate of USB2.0 and 1394. The industrial camera in the invention is a variable magnification area array CCD color camera. CCD color camera integrates photoelectric conversion, charge storage, charge transfer, and signal reading. Using charge as a signal, it has the advantages of low power consumption, low voltage operation, and no lag. Whether it is static acquisition or dynamic acquisition, it can be obtained with...

Embodiment 2

[0068] On the basis of Example 1, after the detection of black foreign objects and white foreign objects is completed, Example 2 adds the following zero-degree incubator 201, spray box 202 and third industrial camera 203, wherein,

[0069] The zero-degree incubator 201 accommodates the infusion bottle 1038 to be detected. The zero-degree incubator 201 is a box-type structure, and its side is provided with a side cover that can be automatically opened and closed. When the mechanical arm 101 triggers the limit switch, the side cover drives the structure. Turn on the power to open the side cover, and the robotic arm 101 extends into the zero-degree incubator 201 to take out the infusion bottle 1038, and moves away from the zero-degree incubator 201. When the set position is reached, the limit switch is released and the side cover is closed. Specifically, the limit switch can be arranged on the slide rail where the carrying platform of the robotic arm 101 is located. When the carry...

Embodiment 3

[0077] Based on Embodiment 1 or 2 of the present invention, Embodiment 3 of the present invention is a method for detecting defective products in the production process of canned infusion bottles reasonably based on big data. More objective, precise and standardized. Effectively reduce the missed detection rate and false detection rate in the sorting and rejection of defective infusion bottles, thereby improving the accuracy of detection. Moreover, automated and intelligent detection can greatly improve the detection efficiency of the production line, greatly shorten the detection time, and save costs. The system is a high-speed online detection system integrating machine vision, precision machinery and real-time control. It mainly realizes the detection of bottle mouth breakage, the detection of contamination on the bottle mouth, the bottom of the bottle and the bottle wall, as well as the detection and rejection of residual liquid in the bottle. and other functions.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com