Bionic structure green bristlegrass-shaped metal oxide nano material and preparation method thereof

A nanomaterial and oxide technology, applied in the directions of alkali metal oxides/hydroxides, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of difficulty in recycling, secondary pollution, hindering large-scale application, etc. Large surface area, the effect of improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

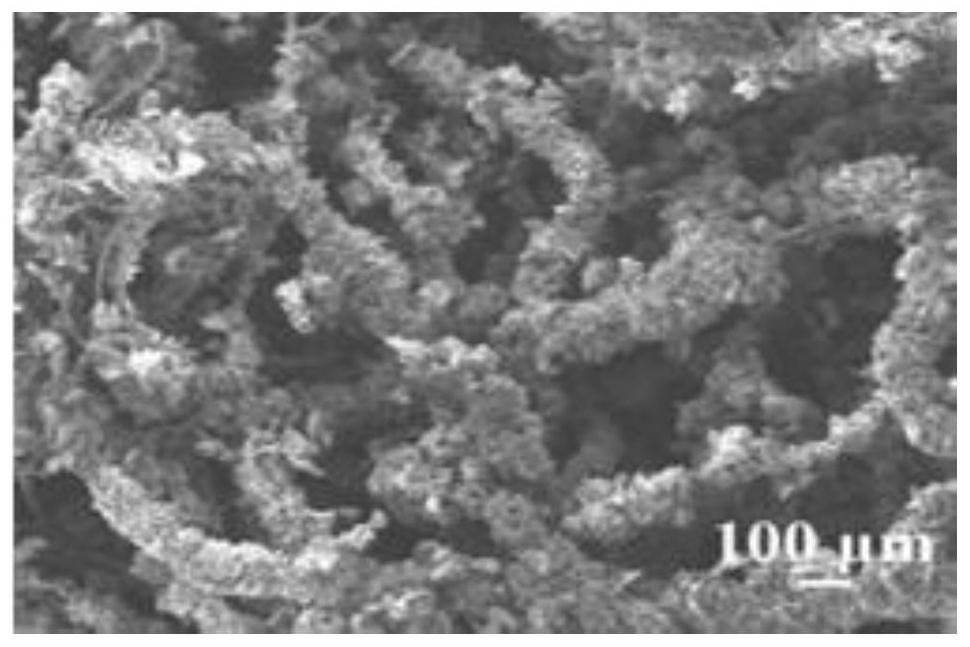

Image

Examples

Embodiment 1

[0031] (1) Dissolve 14.83g of magnesium nitrate, 0.48g of zinc acetate and 18.49g of urea in deionized water, then add 6.28g of oxidized glutathione, stir and mix to obtain a reaction solution.

[0032] (2) Transfer the reaction solution to a hydrothermal reaction kettle for hydrothermal reaction, the temperature of the hydrothermal reaction is 180°C, and the hydrothermal reaction time is 10h, a precipitate is formed in the reaction solution, the reaction is completed, the reaction solution is suction filtered, and the precipitate is washed , and dried to obtain the precursor.

[0033] (3) calcining the precursor under the protection of an inert gas or under a vacuum condition, the calcination temperature is 400° C., and the calcination time is 2 h to obtain a foxtail-like metal oxide nanomaterial.

Embodiment 2

[0035] (1) Dissolve 14.83 g of magnesium nitrate, 0.50 g of titanium chloride and 18.50 g of urea in deionized water, then add 6.29 g of oxidized glutathione, stir and mix to obtain a reaction solution.

[0036] (2) Transfer the reaction solution to a hydrothermal reactor for hydrothermal reaction, the hydrothermal reaction temperature is 150°C, and the hydrothermal reaction time is 12h, a precipitate is formed in the reaction solution, the reaction is completed, the reaction solution is suction filtered, and the precipitate is washed , and dried to obtain the precursor.

[0037] (3) calcining the precursor under the protection of an inert gas or under a vacuum condition at a calcination temperature of 350° C. and a calcination time of 3 h to obtain a foxtail-like metal oxide nanomaterial.

Embodiment 3

[0039] (1) Dissolve 14.83g of magnesium nitrate, 0.5g of zinc acetate, 0.53g of titanium chloride and 25.36g of urea in deionized water, then add 6.47g of oxidized glutathione, stir and mix to obtain a reaction solution.

[0040] (2) Transfer the reaction solution to a hydrothermal reactor for hydrothermal reaction, the temperature of the hydrothermal reaction is 200°C, and the time of the hydrothermal reaction is 8h, a precipitate is formed in the reaction solution, the reaction is completed, the reaction solution is suction filtered, and the precipitate is washed , and dried to obtain the precursor.

[0041] (3) calcining the precursor under the protection of an inert gas or under a vacuum condition at a calcination temperature of 300° C. and a calcination time of 4 h to obtain a foxtail-like metal oxide nanomaterial.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com