Dilute magnetic solid solution type metal anti-corrosion pigment

An anti-corrosion pigment, solid solution technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., to achieve the effect of improving corrosion resistance and corrosion inhibition ability

Inactive Publication Date: 2022-06-10

EAST CHINA UNIV OF SCI & TECH

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Studies have shown that spatial network nanostructures have stronger mechanical resistance, but so far little attention has been paid to the application of cross-network ZnO samples for marine corrosion protection

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

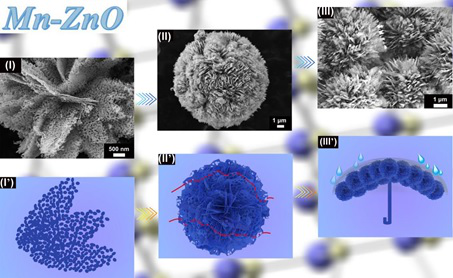

The invention belongs to the technical field of inorganic fine chemical engineering, and particularly relates to a dilute magnetic solid solution type metal anti-corrosion pigment and a preparation method thereof. The mixed-valence Mn-doped ZnO-based diluted magnetic solid solution anti-corrosion pigment with a spatial network structure has the advantages that the invasion of corrosive electrolyte to a metal substrate is effectively prevented by the hydrophobicity and a multi-stage barrier of the mixed-valence Mn-doped ZnO-based diluted magnetic solid solution anti-corrosion pigment; in addition, the ZnO-based solid solution is endowed with dilute magnetism by doping the mixed valence Mn atoms, the electron motion path is deflected or collided with each other by the Lorentz force generated by the system, and the electrochemical corrosion rate is slowed down. The corrosion inhibition performance of the Mn-doped ZnO-based diluted magnetic solid solution type metal anti-corrosion pigment is respectively improved by 455.4% and 73.8% compared with the corrosion inhibition performance of a protective layer prepared by taking epoxy resin and zinc oxide as anti-corrosion pigments. The design strategy based on the microstructure and the magnetic property of the pigment provides a new thought for design and synthesis of a novel metal anti-corrosion pigment.

Description

technical field [0001] The invention belongs to the technical field of inorganic fine chemicals, and in particular relates to a dilute magnetic solid solution metal anticorrosion pigment and a preparation process thereof. Background technique [0002] As we all know, in the metal anticorrosion system, the corrosive medium (such as Cl - 、H 2 O, O 2 ) rapid permeation after passing through the barrier layer and the continuous occurrence of electrochemical reactions are important reasons for the promotion of metal corrosion. Any method that can hinder or cut off the above physical and chemical processes will slow down the damage of the matrix to varying degrees. [0003] Dilute magnetic solid solutions (DMSs) have been widely used in the fields of magnetism, electricity, and optics, and have attracted extensive attention from researchers. Micromagnetic fields generated by multiple magnetic centers in DMSs induce the Lorentz force, thereby deflecting the traveling path of el...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D5/08C09D163/00C01G9/02

CPCC09D163/00C09D5/084C01G9/02C08K2003/2296C08K2201/011C01P2004/80C01P2004/03C08K3/22

Inventor 刘金库陈义香李桐卢怡张敏孙慧萍蔡雨杉赵思睿黄文锵葛云晓

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com