Air filtering material with temperature and humidity response performance and preparation and application thereof

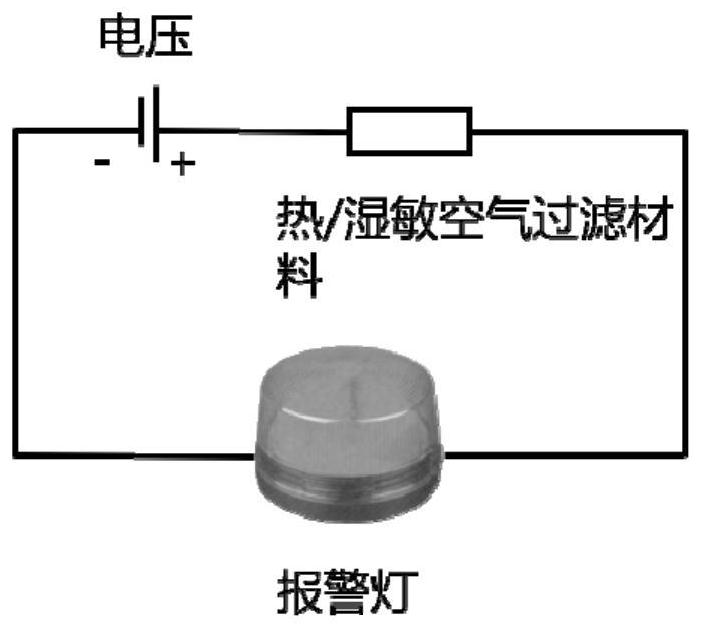

An air filter material, humidity response technology, applied in textiles and papermaking, chemical instruments and methods, fire alarms that rely on radiation, etc. Affect the filtration performance and other problems, to achieve the effect of suppressing the further spread of the flame, fast warning time, and high air filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of an air filter material with temperature and humidity response performance, the steps are as follows:

[0052] (1) phytic acid is dissolved in solvent N-N dimethylformamide (DMF) to obtain solution A; the concentration of phytic acid in solution A is 10wt%;

[0053] (2) adding polyacrylonitrile to the solution A obtained in step (1), and stirring for 5h at a temperature of 60° C. to form a uniform solution B; in solution B, the mass ratio of polyacrylonitrile to phytic acid is 1.2: 1;

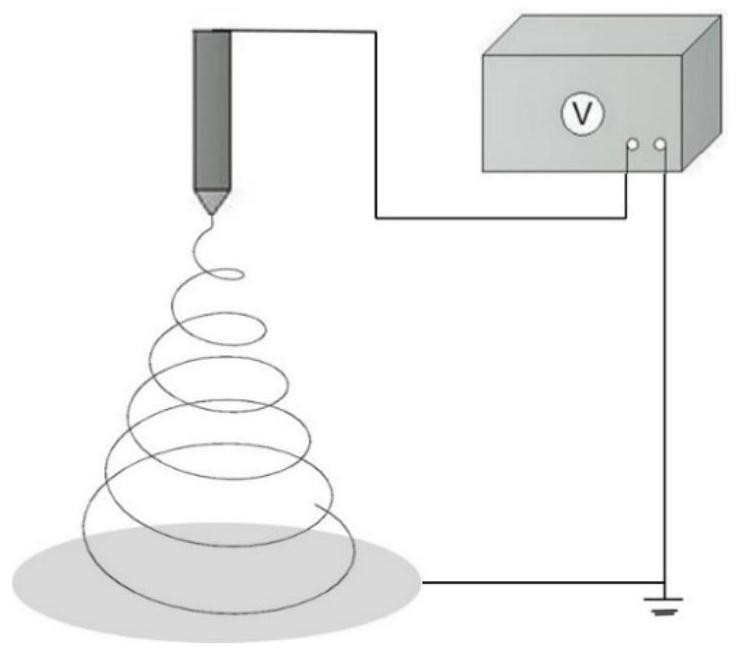

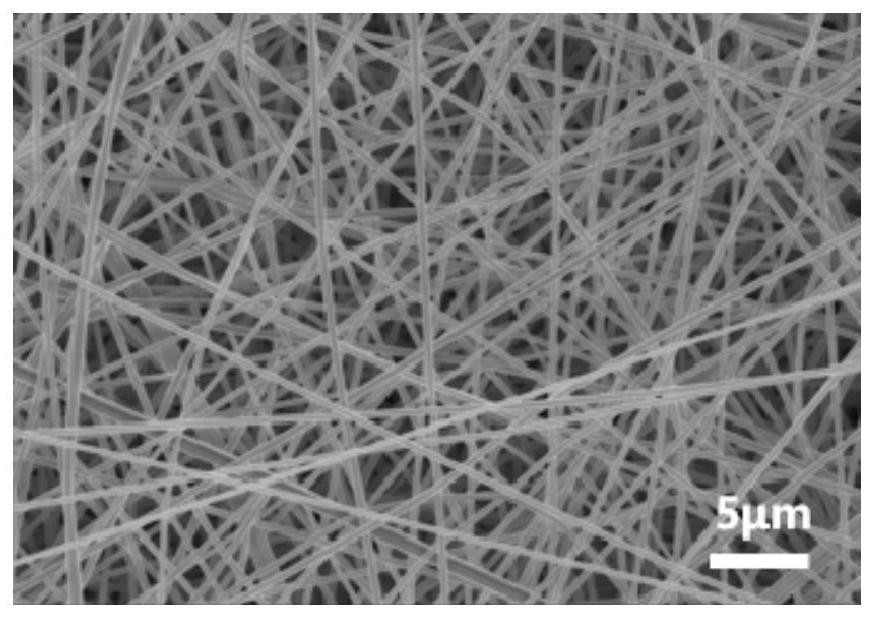

[0054] (3) If figure 1 As shown, the solution B obtained in step (2) was transported to the nozzle with a syringe pump at a flow rate of 1 ml / h. Under the high pressure condition of 20kV, the solution B was drawn by the electric force at the end of the nozzle to form nanofibers. After receiving on the receiving device (roller) for a period of time, a fiber aggregate with random arrangement is formed; wherein, the spinning temperature is 20° C., and the relative h...

Embodiment 2

[0058] A preparation method of an air filter material with temperature and humidity response performance, the steps are as follows:

[0059] (1) phosphoric acid is dissolved in solvent acetone to obtain solution A; the concentration of phosphoric acid in solution A is 7wt%;

[0060] (2) adding polyurethane to the solution A obtained in step (1), and stirring at 20° C. for 5 hours to form a uniform solution B; in solution B, the mass ratio of polyurethane to phytic acid is 2.2:1;

[0061] (3) The solution B obtained in step (2) was transported to the nozzle at a flow rate of 1.5ml / h with a syringe pump, and under the high pressure condition of 15kV, the solution B was drawn by the electric force at the end of the nozzle to form nanofibers, and After receiving on the receiving device (roller) for a period of time, a fiber aggregate with random arrangement is formed; wherein, the spinning temperature is 20° C., and the relative humidity of spinning is 60%;

[0062] (4) take out ...

Embodiment 3

[0065] A preparation method of an air filter material with temperature and humidity response performance, the steps are as follows:

[0066] (1) phytic acid and phosphoric acid are dissolved in solvent formic acid to obtain solution A; In solution A, the mass ratio of phytic acid and phosphoric acid is 1:1, and the sum of the concentrations of phytic acid and phosphoric acid is 8wt%;

[0067] (2) Add PA6 (25038-54-4, Ron's reagent, monomer molecular weight 111.14) to the solution A obtained in step (1), and stir for 8 hours at a temperature of 20°C to form a uniform solution B; solution B , the ratio of polyamide to the sum of the mass of phytic acid and phosphoric acid is 2.5:1;

[0068] (3) The solution B obtained in step (2) was transported to the nozzle at a flow rate of 1.5ml / h with a syringe pump, and under the high pressure condition of 28kV, the solution B was drawn by the electric force at the end of the nozzle to form nanofibers, and After receiving on the receiving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com