In-situ electron diffraction data processing analysis method based on machine learning and application

An electron diffraction and data processing technology, which is applied in image data processing, material analysis using wave/particle radiation, and material analysis, etc. It can solve the problem of difficulty in practice, loss of two-dimensional distribution characteristics of diffraction intensity, and difficulty in eliminating dynamic effects and defects. and other problems to achieve the effect of accurate calibration and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

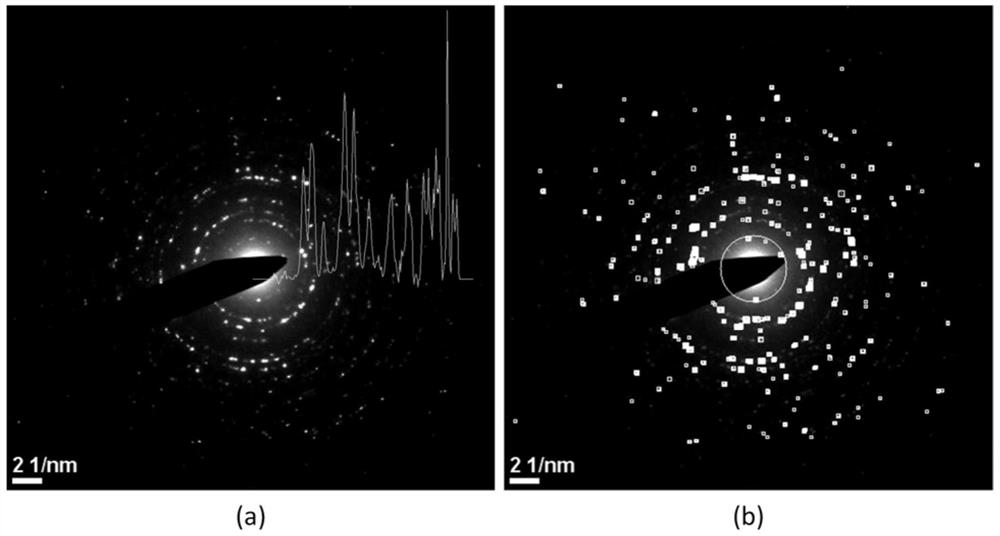

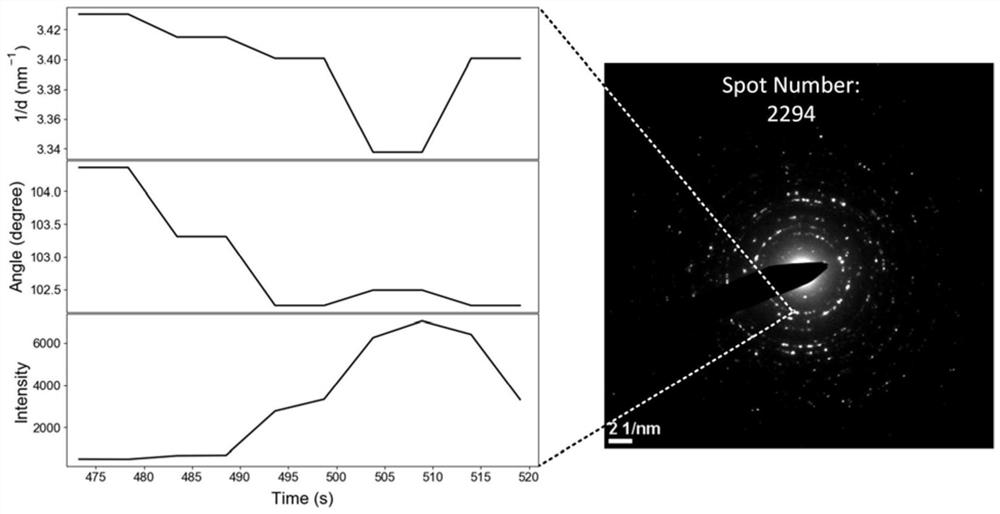

[0041]This embodiment is used to illustrate the in-situ electron diffraction data processing and analysis method based on machine learning of the present invention.

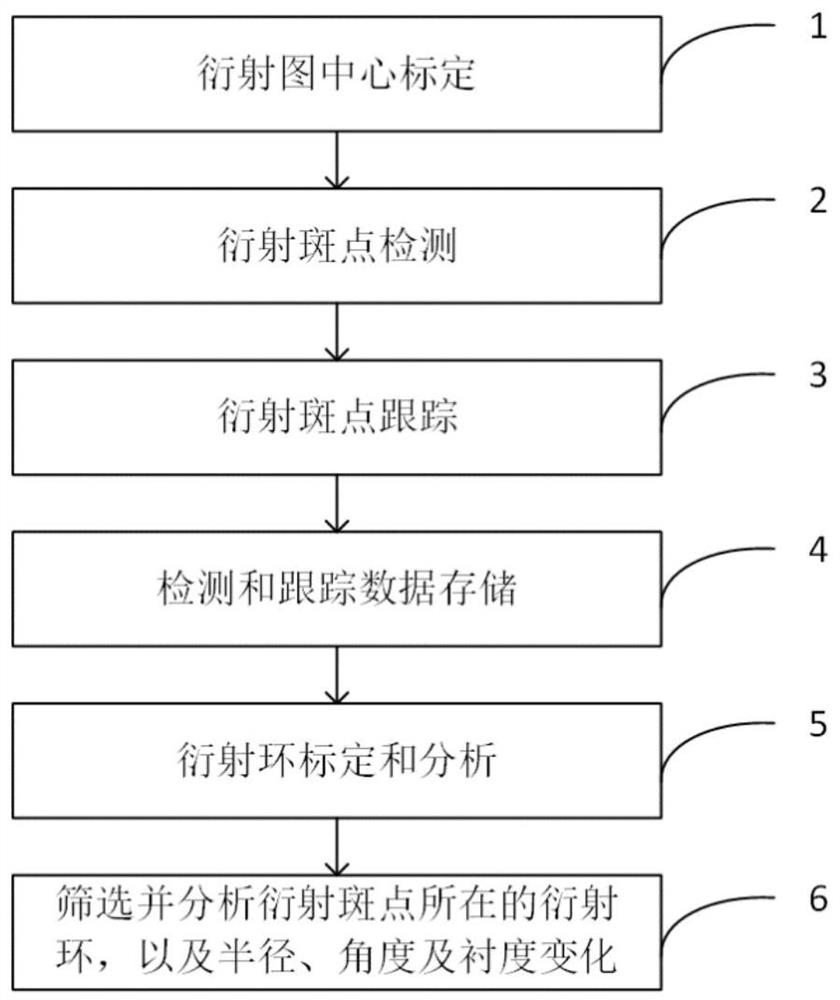

[0042] like figure 2 The flow chart of the in-situ electron diffraction data processing and analysis method based on machine learning shown, specifically includes 6 sub-modules:

[0043] Module 1 is the center calibration method of the diffraction pattern. Usually, the information contained in the diffraction spots close to the transmission spot is not reliable enough, so the first step for in-situ electron diffraction video data processing and analysis is the center calibration of the diffraction pattern, and the calibration results are used for the subsequent detection and tracking of diffraction spots. especially important. Specifically, module 1 mainly includes the following steps:

[0044] Step 1. Obtain the mean image from the input video;

[0045] Step 2. Calculate the Gaussian Mixing Model (Gaussian ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com