Cetirizine hydrochloride tablet and preparation method thereof

A technology of cetirizine hydrochloride and rizine tablets, which is applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., and can solve problems such as adhesion and agglomeration, and shelf-life content decline , to achieve the effect of being suitable for industrial production, simple preparation process and excellent detection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Cetirizine Hydrochloride Tablets

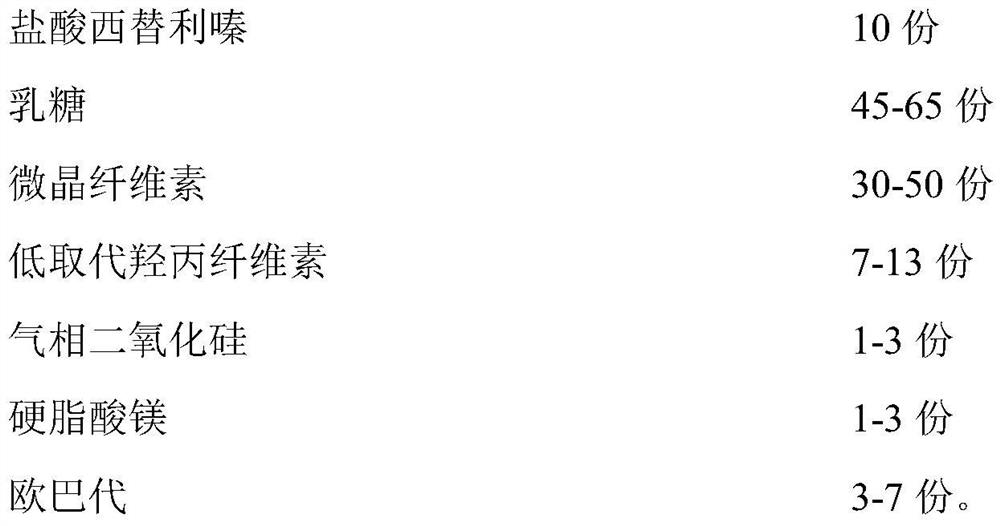

[0029] The prescription consists of 1000 tablets

[0030]

[0031]

[0032] Preparation Process:

[0033] (1) batching process: Cetirizine hydrochloride and fumed silica are pulverized using a 120-mesh bottom mesh;

[0034] (2) Mixing and sieving process: in the mixing and sieving process, the order of adding the raw and auxiliary materials is microcrystalline cellulose, cetirizine hydrochloride fumed silica powder, lactose, low-substituted hypromellose, and the mixing time is 5 minutes. 30 mesh sieve, mix for another 10 minutes, and then mix for 3 minutes with magnesium stearate;

[0035] (3) Tabletting process: using a rotary tablet press, tableting; the tableting speed is 150,000 tablets / hour, and the average tableting main pressure is 15.0KN;

[0036] (4) Coating process: in the coating process, the film-coating premix is added to purified water, stirred for 30 minutes to prepare a suspension coating solution ...

Embodiment 2

[0037] Example 2: Cetirizine Hydrochloride Tablets

[0038] The prescription consists of 1000 tablets

[0039] Element Weight (g) cetirizine hydrochloride 10 Fumed silica 3 microcrystalline cellulose 50 lactose 65 low substituted hydroxypropyl cellulose 13 Magnesium stearate 3 Opadry 7

[0040] Preparation Process:

[0041] Same as Example 1.

Embodiment 3

[0042] Example 3: Cetirizine Hydrochloride Tablets

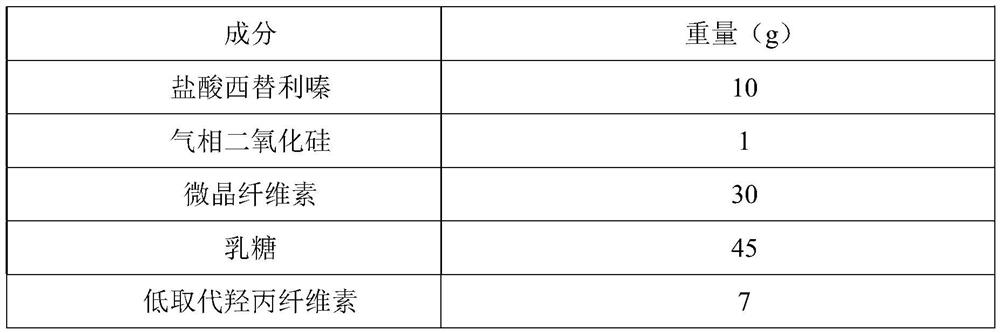

[0043] The prescription consists of 1000 tablets

[0044]

[0045]

[0046] Preparation Process:

[0047] Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com