Preparation method and application of Ni/Zn pre-embedded dication layered vanadium oxide

A technology of double cations and vanadium oxides, applied in chemical instruments and methods, vanadium oxide, nickel compounds, etc., can solve the problems of capacity, rate performance, cycle stability and other incompatibility, and achieve simple and effective synthesis methods and improved structure Stability, effect of increasing electrochemical reaction sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

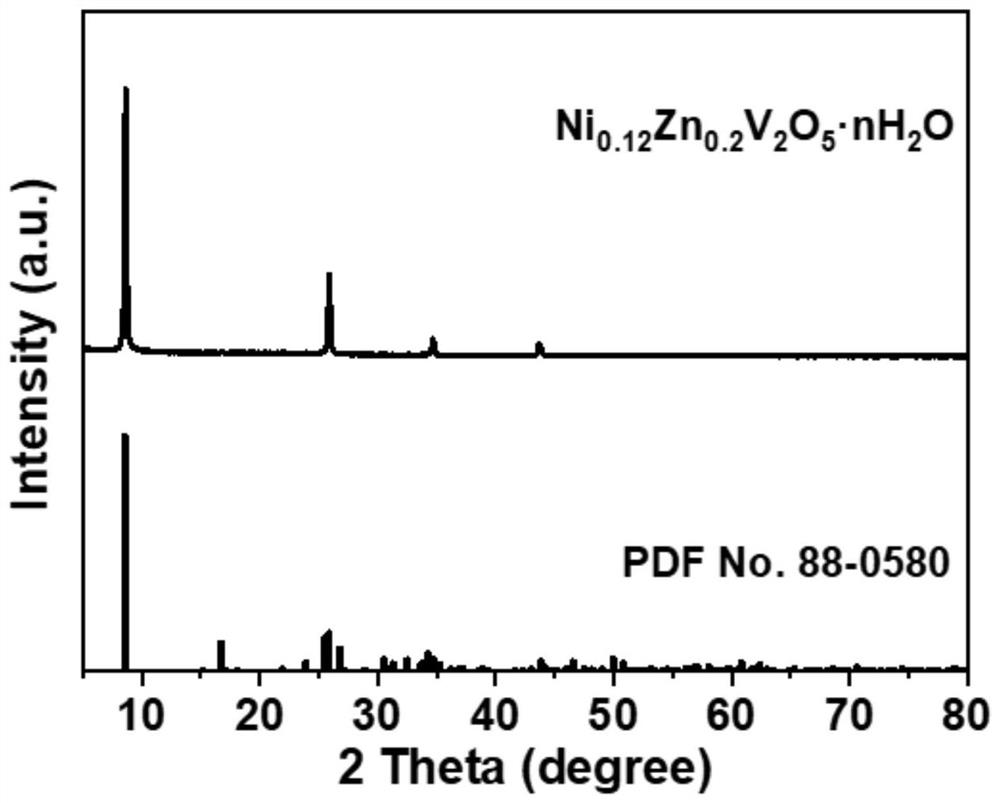

[0031] Example 1: Pre-intercalation of Ni / Zn double cation layered vanadium oxide Ni 0.11 Zn 0.13 V 2 O 5 ·nH 2 Preparation of O

[0032] First, weigh 0.095g of nickel acetate tetrahydrate and fully dissolve it in 26.9mL of deionized water; then continue to weigh 0.084g of zinc acetate dihydrate into the above solution, stir and dissolve; weigh 0.210g of vanadium pentoxide, put it in the above solution Stir and disperse evenly; slowly add 1.7 mL of acetone dropwise to the above solution under magnetic stirring conditions, and after stirring for 5 min, pour the above solution into the Teflon liner of the hydrothermal reactor, move it to the oven, and heat to 200 ℃ and kept the reaction for 72h; after natural cooling, the precipitate collected in the inner liner of the hydrothermal reaction kettle was filtered, washed (three times with deionized water, once with isopropanol), dried, and then placed in a vacuum drying at 60℃. Dry in an oven for 8-10 hours to obtain pre-embed...

Embodiment 2

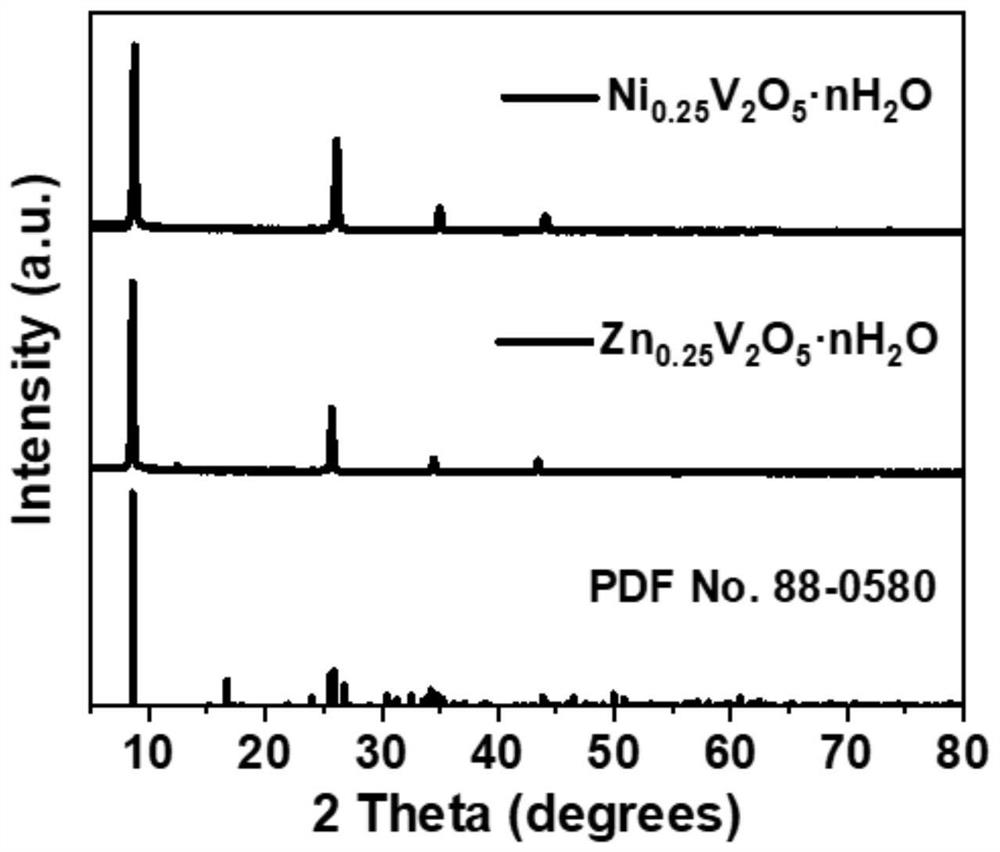

[0034] Example 2: Pre-Embedded Monocationic Layered Vanadium Oxide Zn 0.25 V 2 O 5 ·nH 2 O (corresponding to Ni x Zn y V 2 O 5 ·nH 2 Preparation of the case where x=0 in O)

[0035] First, weigh 0.167g of zinc acetate dihydrate and fully dissolve it in 26.9mL of deionized water; stir and dissolve; weigh 0.210g of vanadium pentoxide, stir and disperse evenly in the above solution; under magnetic stirring conditions, add 1.7mL of acetone Slowly add it dropwise to the above solution, after stirring for 5 minutes, pour the above solution into the Teflon liner of the hydrothermal reaction kettle, move it to the oven, heat it to 200 ° C and keep the reaction for 72 hours; after natural cooling, the hydrothermal The precipitate collected in the inner liner of the reaction kettle is filtered, washed (three times with deionized water and once with isopropanol), dried and placed in a vacuum drying oven at 60°C for 8 to 10 hours to obtain a pre-embedded monocationic layer. Vanad...

Embodiment 3

[0037] Example 3: Pre-intercalation of mono-cationic layered vanadium oxide Ni 0.25 V 2 O 5 ·nH 2 O (corresponding to Ni x Zn y V 2 O 5 ·nH 2 Preparation of the case where y=0 in O)

[0038] First, weigh 0.189g of nickel acetate tetrahydrate and fully dissolve it in 26.9mL of deionized water; stir to dissolve; weigh 0.210g of vanadium pentoxide, stir and disperse evenly in the above solution; under magnetic stirring conditions, add 1.7mL of acetone It was slowly added dropwise to the above solution, and after stirring for 5 minutes, the above solution was poured into the Teflon liner of the hydrothermal reaction kettle, moved to the oven, heated to 200° C. and kept reacting for 72 hours. After natural cooling, the precipitate collected in the inner liner of the hydrothermal reaction kettle was filtered, washed (deionized water three times, isopropanol once), dried, and then placed in a vacuum drying oven at 60 °C for 8 to 10 hours. , to obtain pre-intercalated mono-ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com