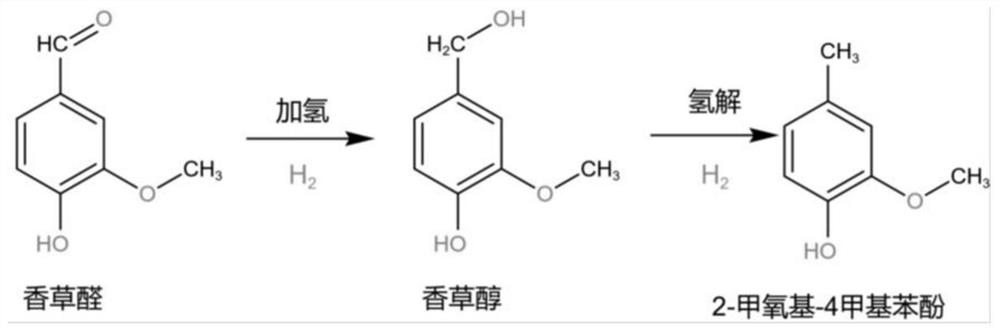

Method for preparing 2-methoxy-4-methylphenol from biomass-based vanillin

A technology based on methylphenol and vanillin, applied in the field of biomass-based vanillin to prepare 2-methoxy-4-methylphenol, can solve the problems of high cost and unfavorable industrial production, achieve low price and avoid catalytic activity Not high or deactivated, the effect of changing electronic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] 1. The preparation method of the catalyst:

[0030] 1.1 mL of methyl methacrylate, 21 mL of styrene, 0.92 mL of acrylic acid and 0.49 g of ammonium bicarbonate were added to 100 mL of deionized water, added to a round-bottomed flask, heated and stirred in an oil bath until the temperature rose to 0.53 g of ammonium persulfate was added at 70° C., and then heated to 80° C. and stirred for 12 h. After stirring, centrifugation and washing were completed, and the centrifuged samples were obtained into polystyrene nanospheres. Polystyrene nanospheres can not only be used as the hard template of the catalyst, but also easily decomposed at high temperature, so there is no need to specially remove the template, and the polystyrene nanospheres also have the characteristics of uniform particle size distribution.

[0031] The polystyrene nanospheres and 2-methylimidazole were added to a round-bottomed flask containing deionized water, and the mixing mass ratio of the polystyrene n...

Embodiment 1

[0035] Example 1 (Co@NHCS-600)

[0036] 0.3 g of polystyrene nanospheres, 5.5 g of 2-methylimidazole and 20 mL of deionized water were added to a round-bottomed flask, and after sonicating for 30 min, transferred to an oil bath and stirred; 1.55 mmol of cobalt nitrate hexahydrate was added. It was added to 3 mL of deionized water, and then transferred to the previous round-bottomed flask. During the transfer, it was added dropwise. After the addition was completed, the mixture was stirred at room temperature for 6 h. After stirring, the samples were centrifuged and washed with deionized water and methanol (water and methanol were washed twice each), and the washed samples were placed in an oven at 110° C. overnight. The samples were calcined in a tube furnace at a calcination temperature of 600 °C, kept for 4 h, and the heating rate was 5 °C / min.

Embodiment 2

[0037] Example 2 (Co@NHCS-900)

[0038] 0.3 g of polystyrene nanospheres, 5.5 g of 2-methylimidazole and 20 mL of deionized water were added to a round-bottomed flask, and after sonicating for 30 min, transferred to an oil bath and stirred; 1.55 mmol of cobalt nitrate hexahydrate was added. It was added to 3 mL of deionized water, and then transferred to the previous round-bottomed flask. During the transfer, it was added dropwise. After the addition was completed, the mixture was stirred at room temperature for 6 h. After stirring, the samples were centrifuged and washed with deionized water and methanol (water and methanol were washed twice each), and the washed samples were placed in an oven at 110° C. overnight. The samples were calcined in a tube furnace at a calcination temperature of 900 °C, kept for 4 h, and the heating rate was 5 °C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com