Fluorescent material for rapidly detecting explosives as well as preparation method and application of fluorescent material

A technology for fluorescent materials and explosives, applied in the field of explosives detection, can solve the problems of high price, not easy to carry, difficult to quickly detect online, etc., and achieve the effect of easy implementation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Synthesis of Fluorescent Material A for Rapid Detection of Explosives:

[0037] (1) In a 500 mL round-bottomed flask, add a magnetic stirring bar, add 11 g (70 mmol) of 1,8-diaminonaphthalene, 7.8 g (20 mmol) of 1,3,5-tris(p-formylphenyl)benzene, add 1.9 g (10 mmol) of sodium metabisulfite, 150 mL of ethanol, after stirring and dissolving, heat under reflux at 100 °C for 2 hours, stop heating, add an appropriate amount of dilute hydrochloric acid, adjust the pH to neutrality, and then precipitate is formed, filter, dry, and recrystallize to obtain the precipitation. Product, the preform is yellow powder, 8.2g.

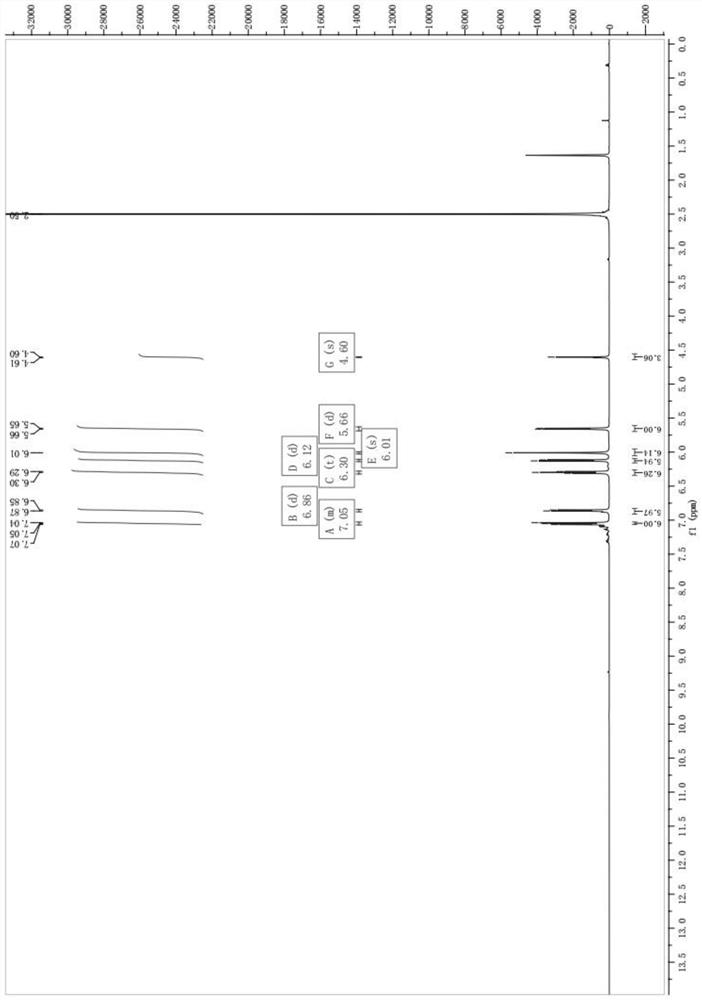

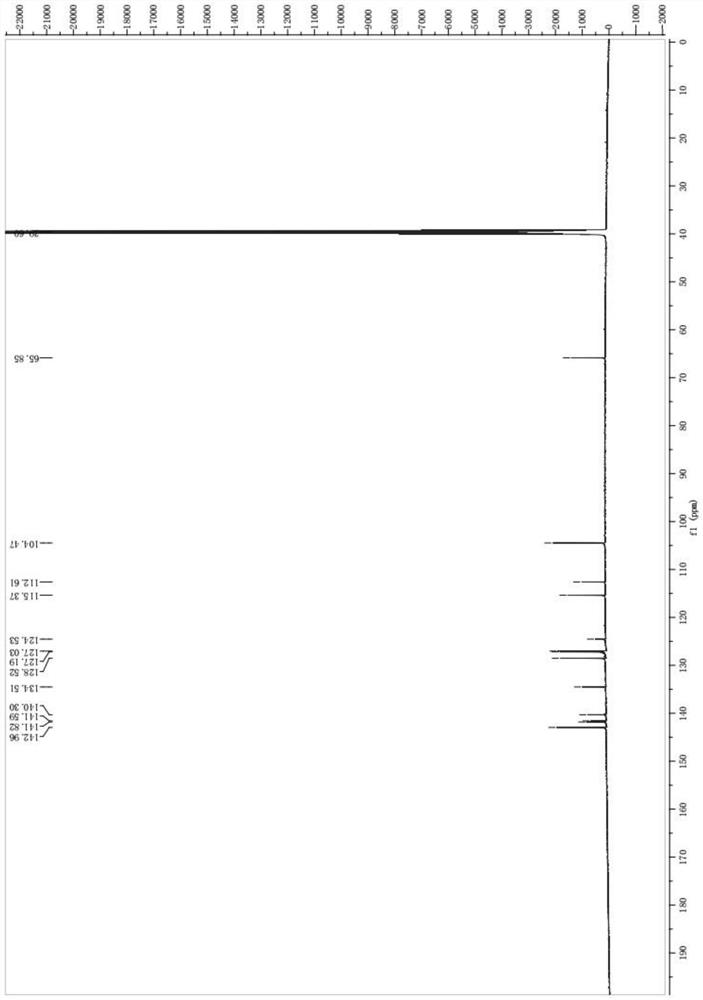

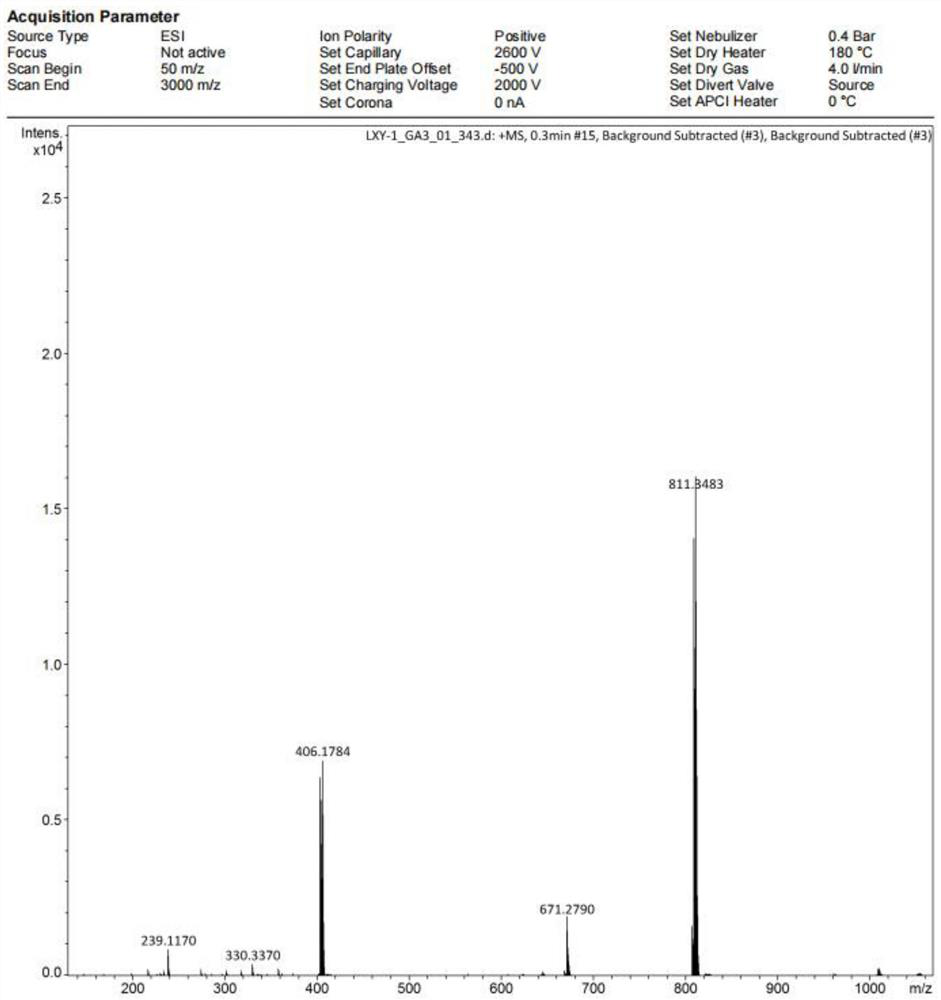

[0038] The structure of the preform was characterized by NMR and mass spectrometry, and the obtained 1 H NMR spectrum as figure 1 shown, 13 C NMR spectrum as figure 2 As shown, the mass spectrum is as image 3 The specific data are as follows:

[0039] 1 H NMR(600MHz,DMSO)δ7.07-7.03(m,6H),6.86(d,J=8.2Hz,6H),6.30(t,J=7.8Hz,6H),6.12(d,J=8.1Hz , 6H), 6.01(...

Embodiment 2

[0045] Explosive Detection:

[0046]10 mg of the fluorescent material A prepared in Example 1 was dissolved in 3 mL of tetrahydrofuran, and 200 μL of the solution was drawn with a pipette and evenly coated on the filter paper strip. After the solvent was volatilized, an explosives detection test paper was prepared.

[0047] The prepared test paper is pale yellow under white light and blue under 254nm ultraviolet lamp. Add 30uL (0.01mg / mL) TNT methanol solution dropwise to the filter paper strip, the filter paper strip turns blue under white light, after the solvent evaporates, the filter paper strip is still blue, under 254nm UV lamp, the color is better than before fade. It can be seen that the fluorescent material A prepared in Example 1 can realize rapid naked-eye detection of TNT.

[0048] Dissolve 10 mg of the fluorescent material A prepared in Example 1 in 3 mL of tetrahydrofuran and place it in a cuvette for UV detection. After adding 30 μL (0.01 mg / mL) of TNT methano...

Embodiment 3

[0052] Synthesis of Fluorescent Material B for Rapid Detection of Explosives:

[0053] Using the prefabricated product prepared in Example 1 as a raw material, in a 500 mL round-bottomed flask, a magnetic stirring bar was added, and 1,3,5-tris(1H-piperidin-2-yl)benzene 5.8g (10mmol), 1,3,5-tris(1H-piperidin-2-yl)benzene was added. 4.1 g (15 mmol) of 8-dibromooctane, 2.4 g (30 mmol) of 50% sodium hydroxide solution, 740 mg (2 mmol) of TBAI, 150 mL of acetone, stirred at room temperature for 24 hours, stopped stirring and washed with suction to obtain fluorescent material B , as a brown solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com