Method for one-step low-temperature preparation of large-particle-size single-crystal ternary positive electrode material

A positive electrode material, large particle size technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of wide particle size distribution, high sintering temperature, poor consistency, etc., to achieve large particle size, high mechanical strength, and stable structure good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

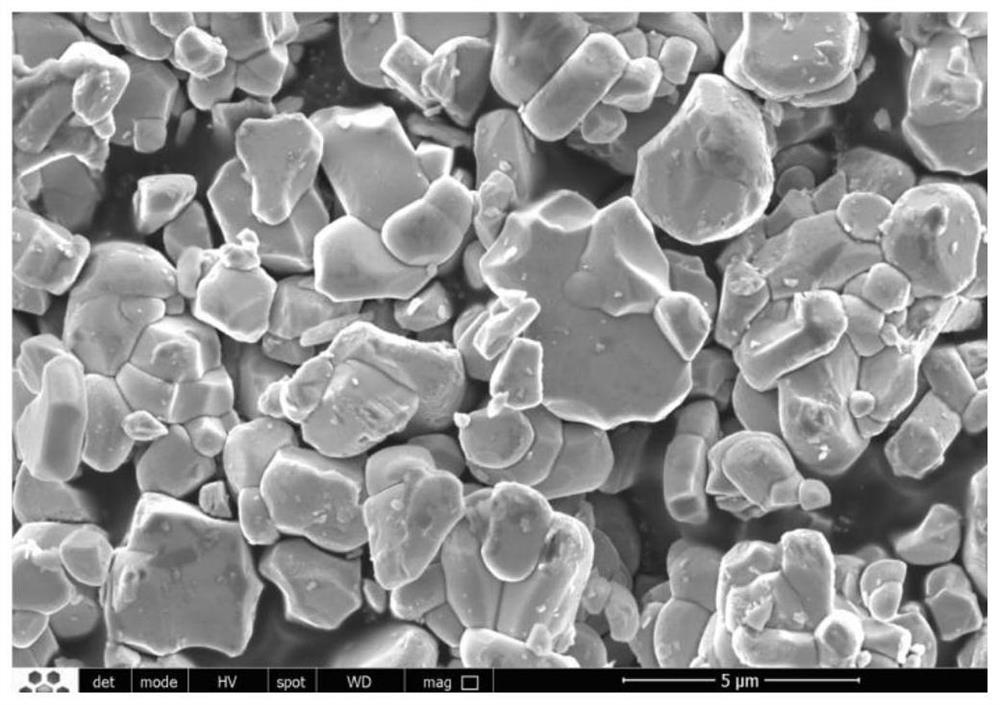

[0039] Accurately weigh 3mol Ni according to Li:(Ni+Co+Mn)=1.03 0.90 Co 0.06 Mn 0.04 (OH) 2 Precursor, 3.09mol LiOH·H 2 O, 0.003mol (0.1mol%) nano-strontium titanate, the precursor, lithium salt and nano-flux were mixed in a high-speed mixer for 3 minutes; in an oxygen atmosphere ≥ 98%, the air flow rate was controlled to 4.8m 3 / h, raise the temperature to 500°C for 3 hours at a heating rate of 3°C / min, continue to increase to 835°C at the same heating rate and maintain a constant temperature for 12 hours, and cool to room temperature with the furnace to obtain a ternary cathode material.

Embodiment 2

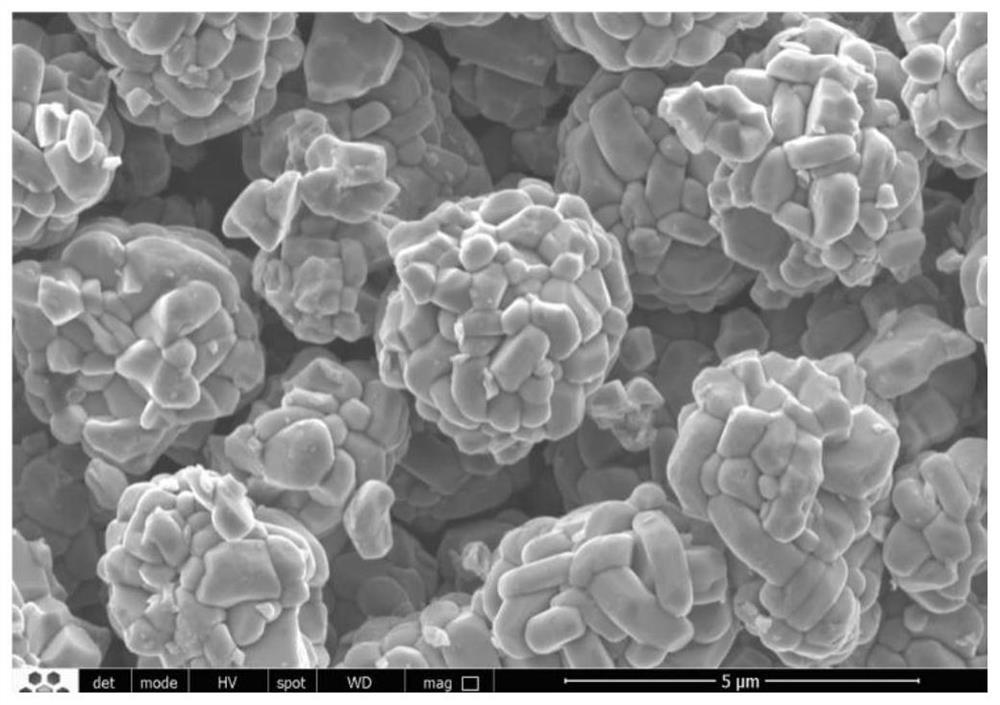

[0041] Accurately weigh 3mol Ni according to Li:(Ni+Co+Mn)=1.03 0.90 Co 0.06 Mn 0.04 (OH) 2 Precursor, 3.09mol LiOH·H 2 O, 0.0015mol (0.05mol%) nano-strontium titanate, the precursor, lithium hydroxide monohydrate, nano-flux were mixed in a high-speed mixer for 3 minutes; in an oxygen atmosphere ≥ 98%, the control air flow was 4.8m 3 / h, raise the temperature to 500°C for 3 hours at a heating rate of 3°C / min, continue to rise to 815°C at the same heating rate and maintain the constant temperature for 12 hours, and cool to room temperature with the furnace to obtain a ternary cathode material.

Embodiment 3

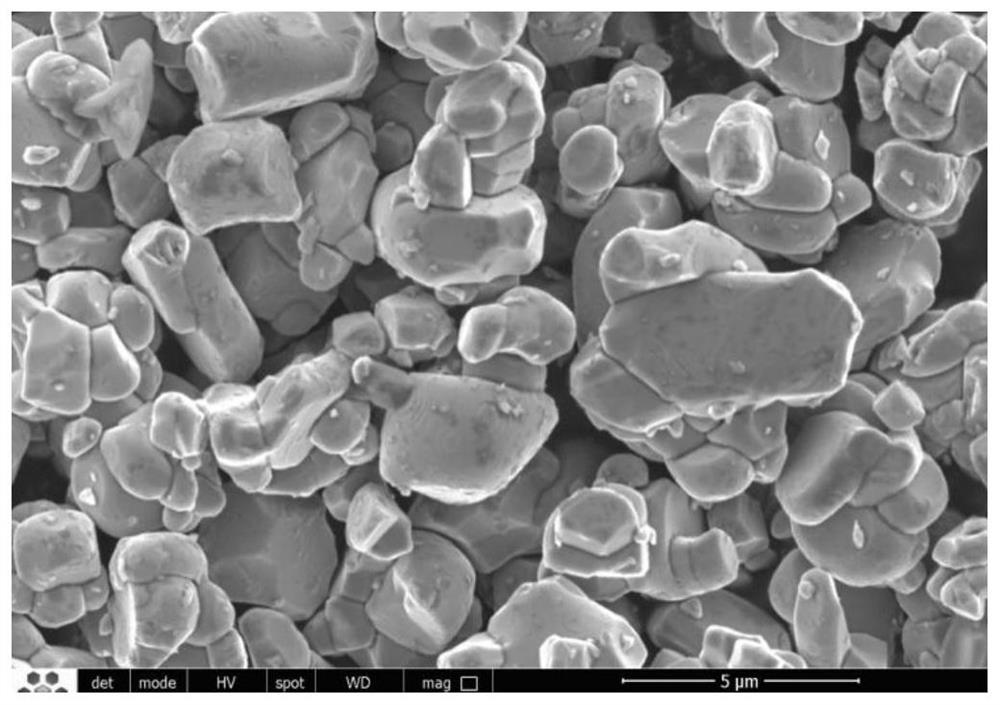

[0043] Accurately weigh 3mol Ni according to Li:(Ni+Co+Mn)=1.03 0.90 Co 0.06 Mn 0.04 (OH) 2 Precursor, 3.09mol LiOH·H 2 O, 0.006mol (0.2mol%) nanometer strontium titanate, the precursor, lithium hydroxide monohydrate, and nanoflux were mixed in a high-speed mixer for 3 minutes; in an oxygen atmosphere ≥98%, the control air flow was 4.8m 3 / h, heat up to 500°C for 3 hours at a heating rate of 3°C / min, continue to rise to 825°C at the same heating rate and maintain a constant temperature for 12 hours, and cool to room temperature with the furnace to obtain a ternary cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com