Defoaming agent for phosphogypsum washing and preparation method thereof

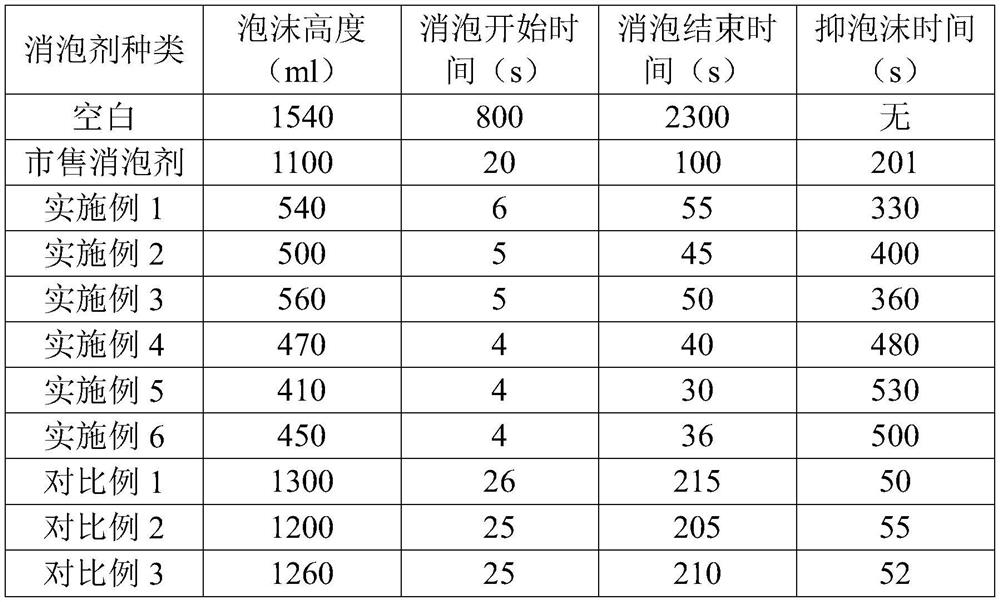

A technology of defoamer and phosphogypsum, which is applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve the problems of lack of pertinence, long foam suppression time, short defoaming time, etc., and achieve enhanced effect , Improve the anti-foaming effect and the effect of fast defoaming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put 10 parts of the main active ingredient polyoxypropylene glycerol ether and 5 parts of carboxylate palmitic acid into a mixing pot for premixing, stir at 20-40°C for 10-20min, add 30 parts of water and heat to 40-70°C , stir well until uniform. Then add 5 parts of surfactant sodium dodecyl benzene sulfonate, 5 parts of foam suppressor fatty alcohol polyoxyethylene ether carboxylate sodium and fully stir and mix, stir for 10-20min until the surfactant and main active ingredient mixture are fully mixed, Add 5 parts of sodium dihydrogen phosphate, an inorganic salt, stir evenly, and cool to below 40° C. to obtain the desired defoamer.

Embodiment 2

[0027] Put 10 parts of fatty alcohol polypropylene ether, 10 parts of ethyl vinyl polyether, 5 parts of carboxylate dodecyl benzene sulfonic acid, and 10 parts of polyol fatty acid ester into the mixing pot for premixing, 20-40 parts Stir at ℃ for 10-20min, add 60 parts of water, heat up to 40-70 ℃, stir well until uniform. Then add 15 parts of surfactant sodium dodecyl benzene sulfonate, 15 parts of foam suppressor fatty alcohol polyoxyethylene ether carboxylate and fully mix, stir for 10-20min until surfactant and main active ingredient mixture are fully mixed, Then add 10 parts of sodium dihydrogen phosphate, an inorganic salt, stir evenly, and cool to below 40° C. to obtain the desired defoamer.

Embodiment 3

[0029] Put the main active ingredients 10 parts of ethyl vinyl polyether, 5 parts of polyethylene glycol ether, 5 parts of carboxylated isopropyl palmitate, 5 parts of polyol fatty acid ester into the mixing pot and pre-mixed at 20-40 ℃ Stir for 10-20min, add 45 parts of water, heat up to 40-70°C, and fully stir until uniform. Then add 10 parts of surfactant organic amine soap, 10 parts of foam inhibitor sodium phthalate mono-fatty alcohol ester and fully stir and mix, stir for 10-20min until the mixture of surfactant and main active ingredient is fully mixed, and then add inorganic sodium sulfate 8 parts, stir evenly, and cool to below 40°C to obtain the desired defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com