Preparation method of non-fibrous potassium octatitanate

A kind of potassium octatitanate, non-fibrous technology, applied in the field of preparation of non-fibrous potassium octatitanate, can solve the problems of high production cost, complex production process, blocked channels and the like, and achieves high wear resistance and synthesis technology. Simple, friction-stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

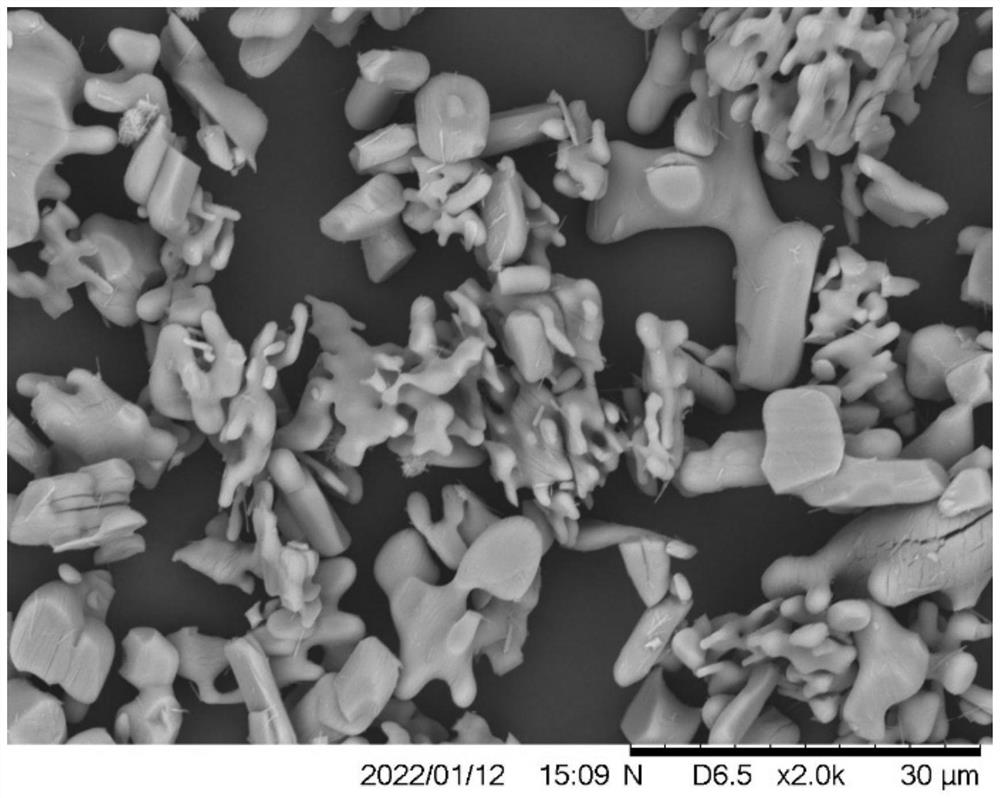

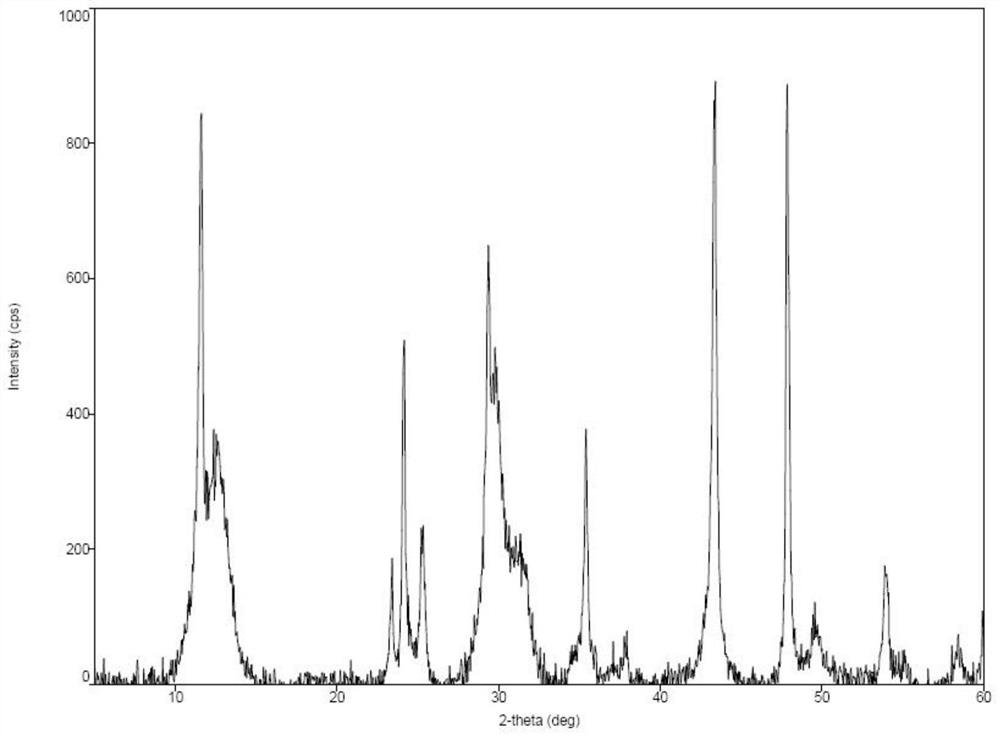

[0019] The titanium-containing raw material (the titanium-containing raw material is anatase titanium oxide with a content of more than 98%) and the potassium-containing raw material (the potassium-containing raw material is a mixture of potassium carbonate and potassium bicarbonate, wherein potassium carbonate:potassium bicarbonate=1:1 ) According to the ratio of Ti / K2=2.0, mix the raw materials, put the pulverized raw materials into a high-temperature furnace for calcining, set the firing temperature to 900°C, the heating rate: 5°C / min, and the firing time to 4 hours, then press 3°C / min, down to room temperature. The fired product is pulverized by a hammer mill, and the pulverized material and the titanium-containing raw material are mixed according to a mass ratio of 1:2, and 3% potassium phosphate is added at the same time.

[0020] Put the uniformly mixed raw materials into a high-temperature furnace for calcination, set the calcination temperature to 1200°C, heat up at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com